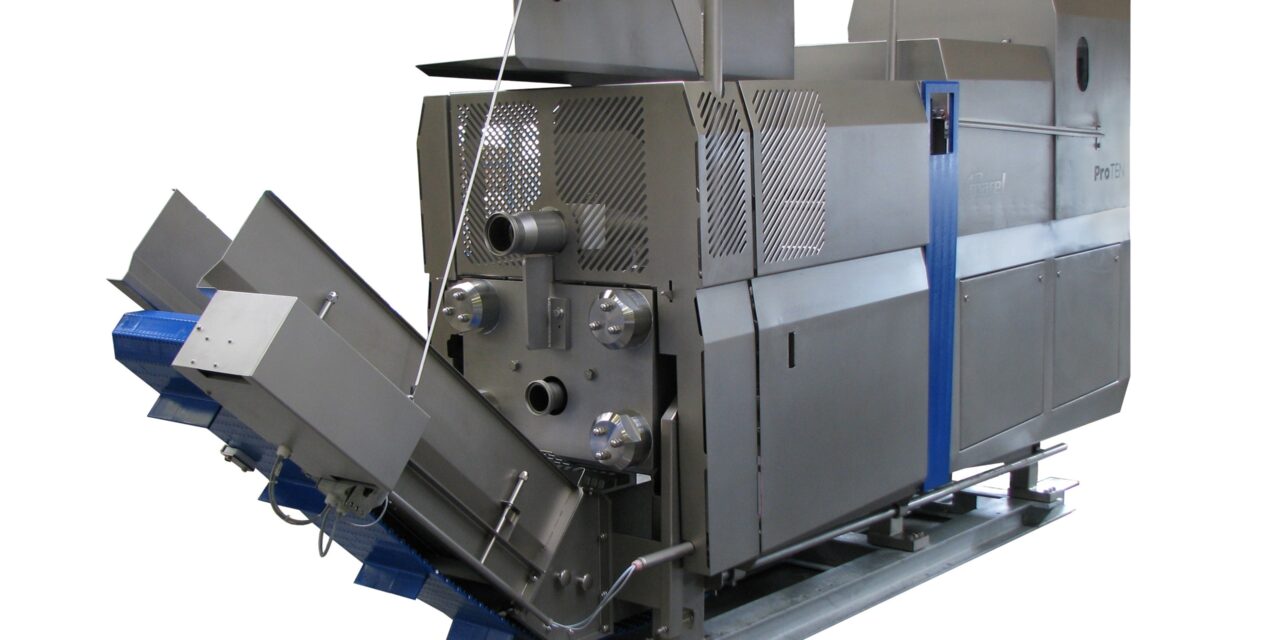

The Townsend AT 21-620 automated trimmer is suitable for processing meat.

2627x1016x1895 mm 16,5 kW 771 kg

Special Features

Technical Specifications

Dimensions(LxWxH)

Power

Weight

Additional information