As a specialist for industrial cheese dicing, the CASAN 200 is extremely tough and thus offers security in production. The machine is loaded fully automatically. Two Euroblocks can be fed in lying on top of one another. The opening of the cutting chamber is generously dimensioned with 240 mm. There are numerous possibilities for the feeding and discharge of products.

Special features

- High production reliability for orientation to industrial demands

- Compact Design

- Operation possible from both sides of the machine thanks to the rotatable display and hopper changeover

- Automatic discharge of product left-overs via residue channel (patented) with left-over material return to the cutting chamber

- Automatic feed pressure control: Considerable energy savings compared with conventional systems and more gentle on the product

- Top cutting pattern thanks to sensor-based cutting technology (TREIF patent)

- Data transfer via USB stick

Technical Specifications

| Max. output |

3000 kg/hour |

| Max. cut-off length |

1–50 mm |

| Processing quantity |

500 cuts/minute |

| Cutting chamber size (WxH): |

200×120 mm |

| Max. infeed length |

550 mm |

| Housing dimensions (LxWxH) |

3894x2850x2183 |

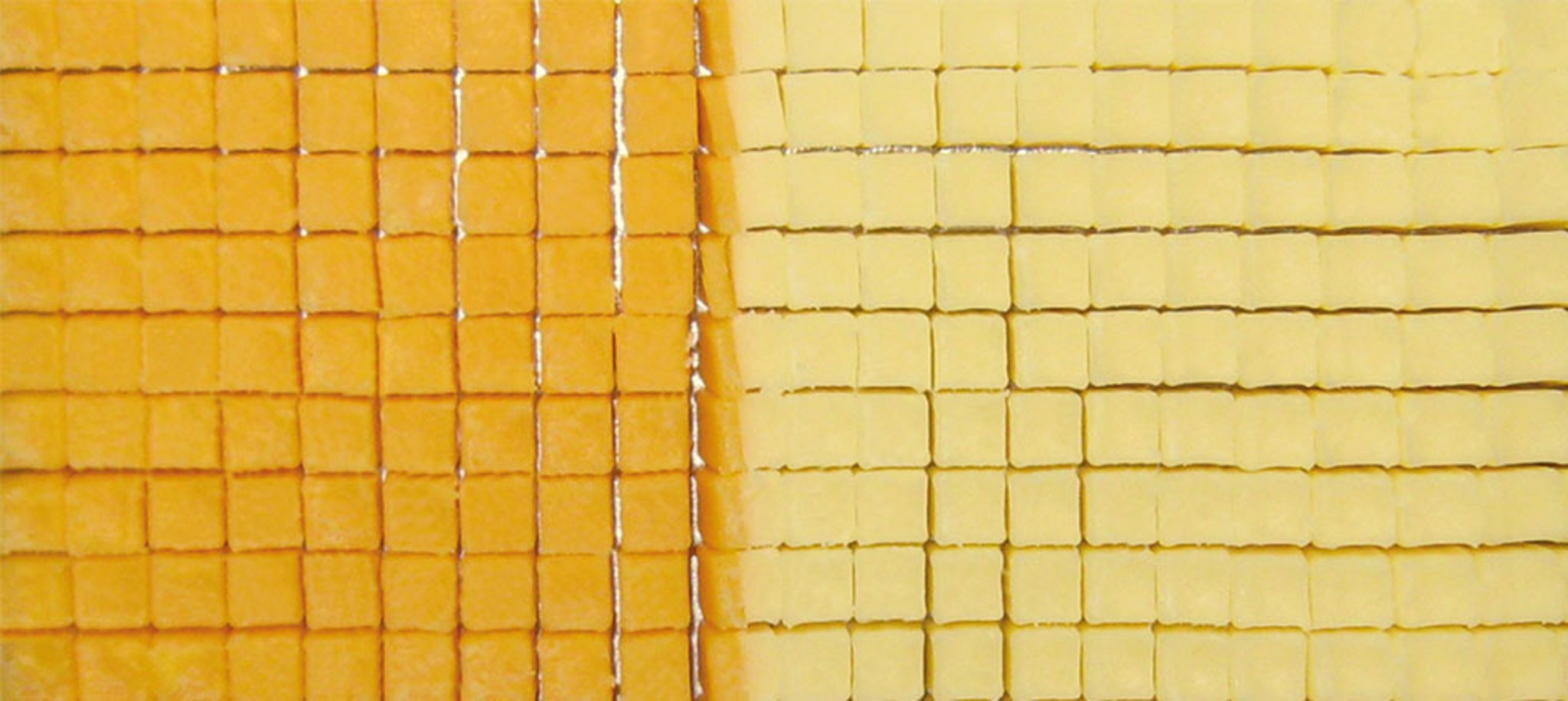

| Gridsets |

5/6/8/10/12/15/17/20/24/30/40/60 mm |

Additional information