High-speed cutting with extremely high throughput and continuously stands for. TREIF developed the FALCON evolution which achieves a massive increase in performance. The unbeatable speed is especially due to the far-sighted optimisation of the individual processes.

Special Features

- Forming system for boneless meat

- In-line weighing system

- Continuous loading – top weight results (4D camera system completely captures and calibrates the product)

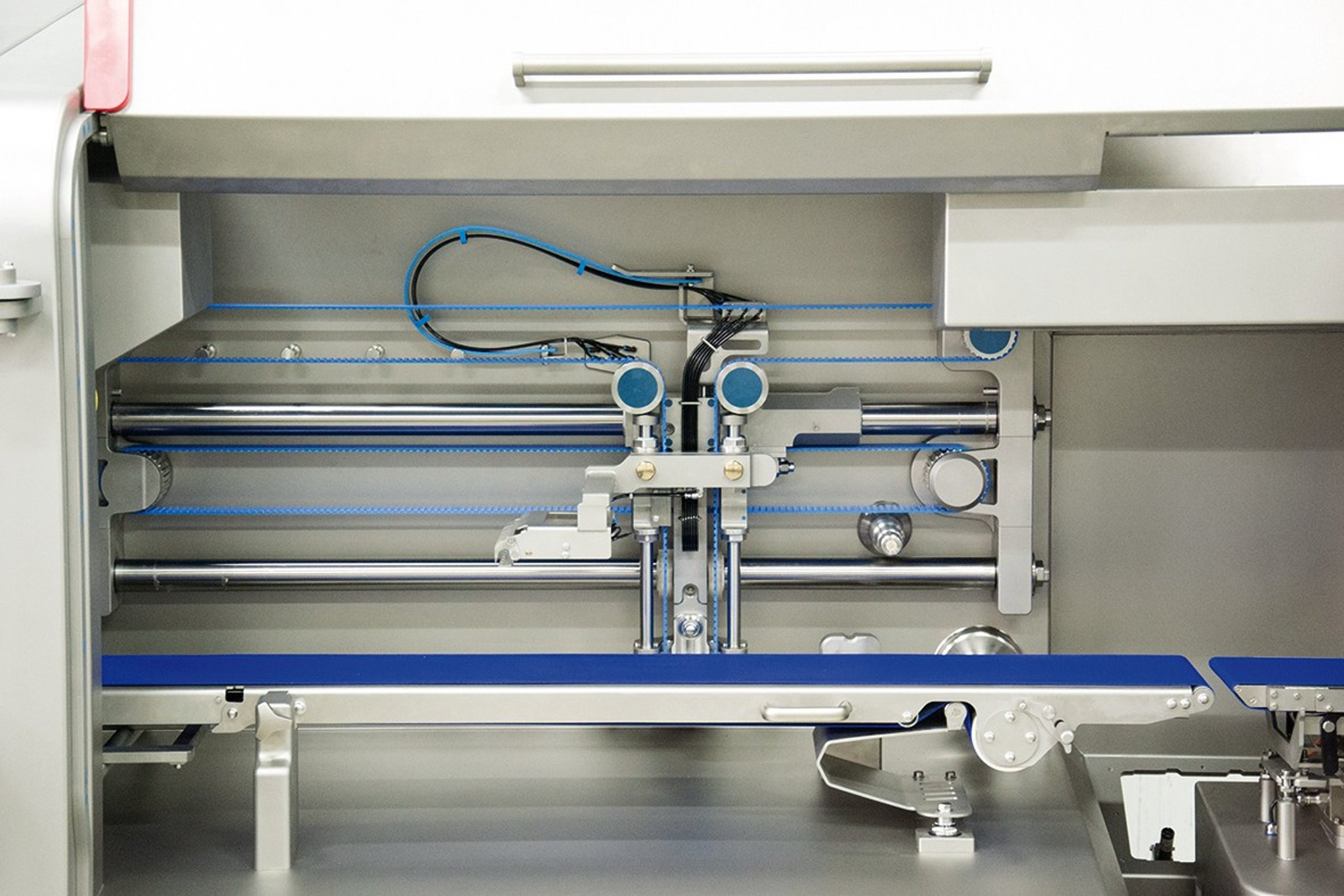

- Cutting system with a special Servo knife

- Fewer personnel hours through grouping unit for grouping the cut portions (optional)

- Ideal for cutting according to slice thickness or weight specification

- Portioning of a product in various weight categories at the press of a button

- TREIF robotic: fully-automatic sorting and placement process using robot technology

- Optimised process times during loading and cutting processes for increasing performance

- Safe cutting process through following retainer including product-contour guided blade control

Technical Specifications

| Max. output | 550 cuts per minute |

| Cross section of product (WxH) | up to 260×180 mm |

| Max. infeed length | gripped 800 mm |

| Housing dimensions (WxH) | 1767×2522 mm |

| Length with pre-belt without check weigher | 4422 – 4688 depending on model |

| Applications | up to -4 °C |

Additional information