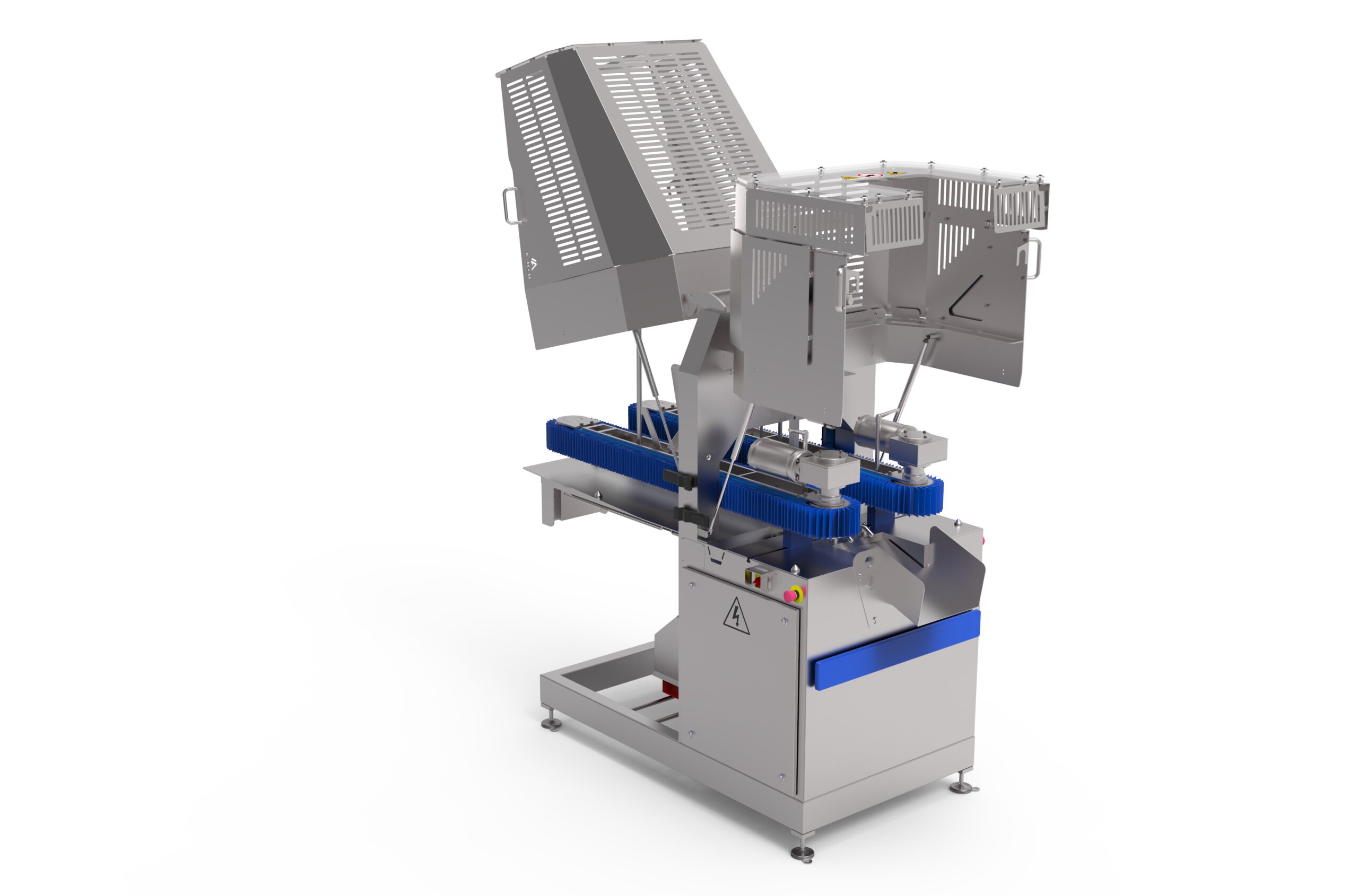

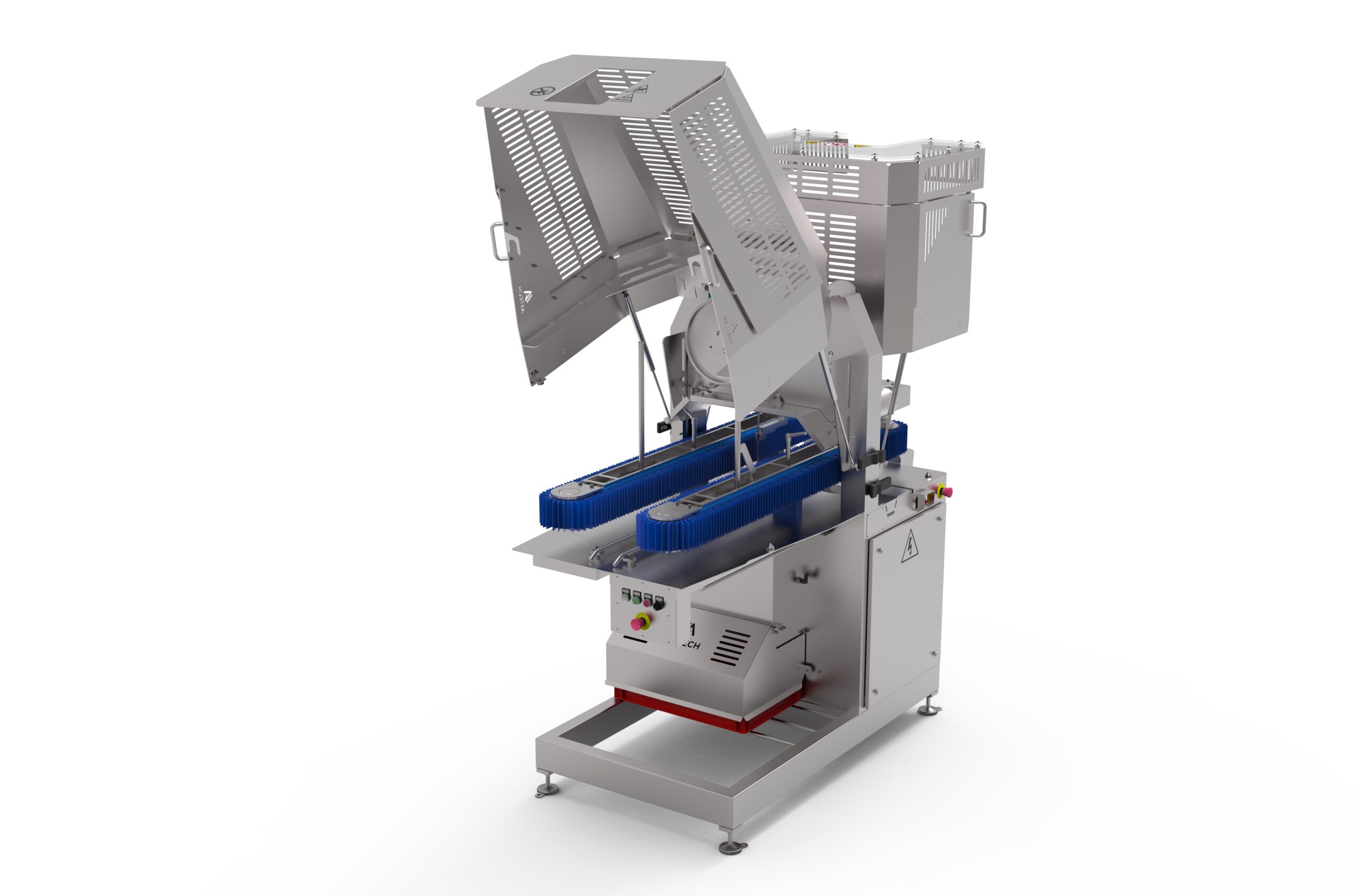

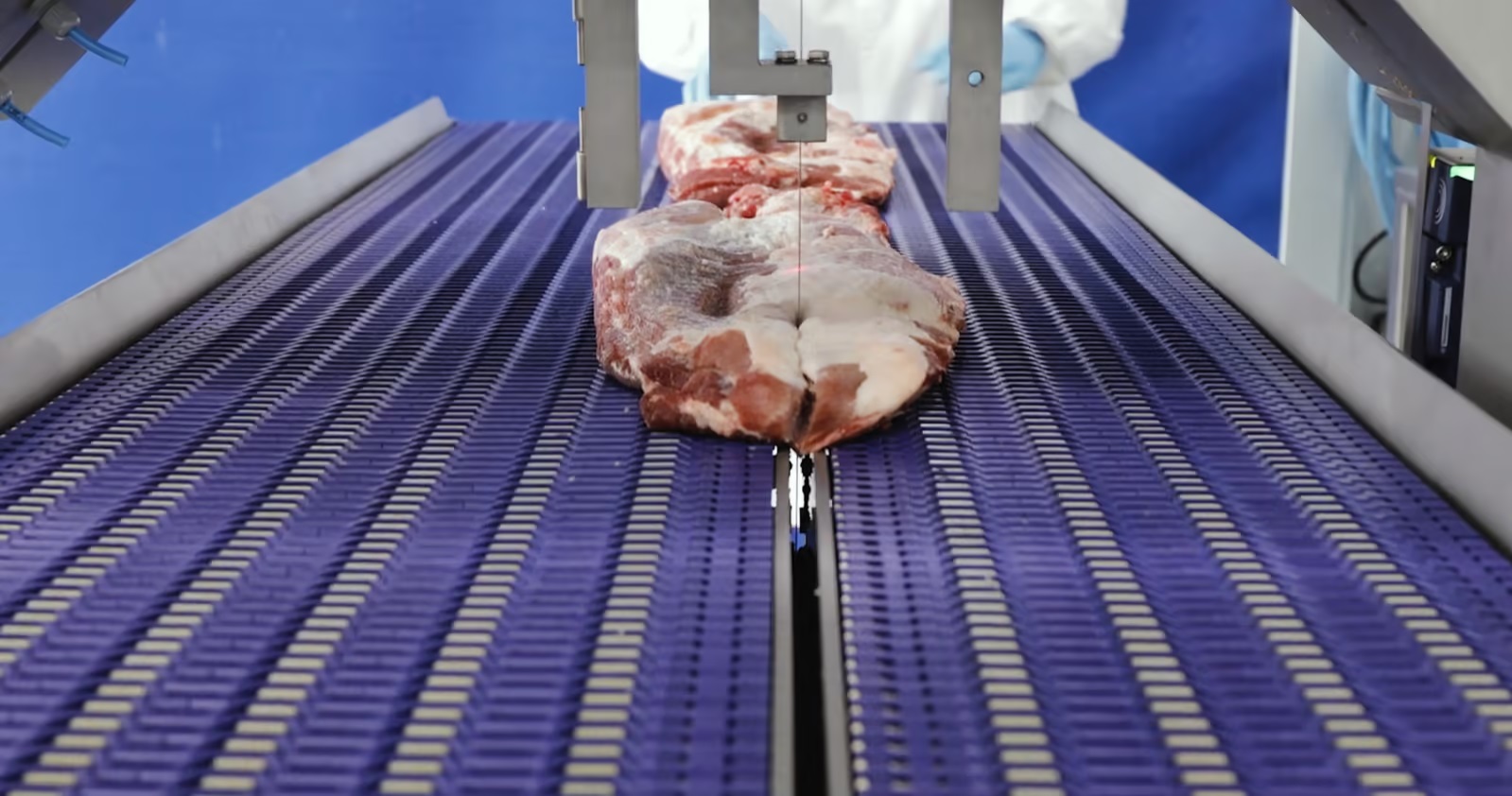

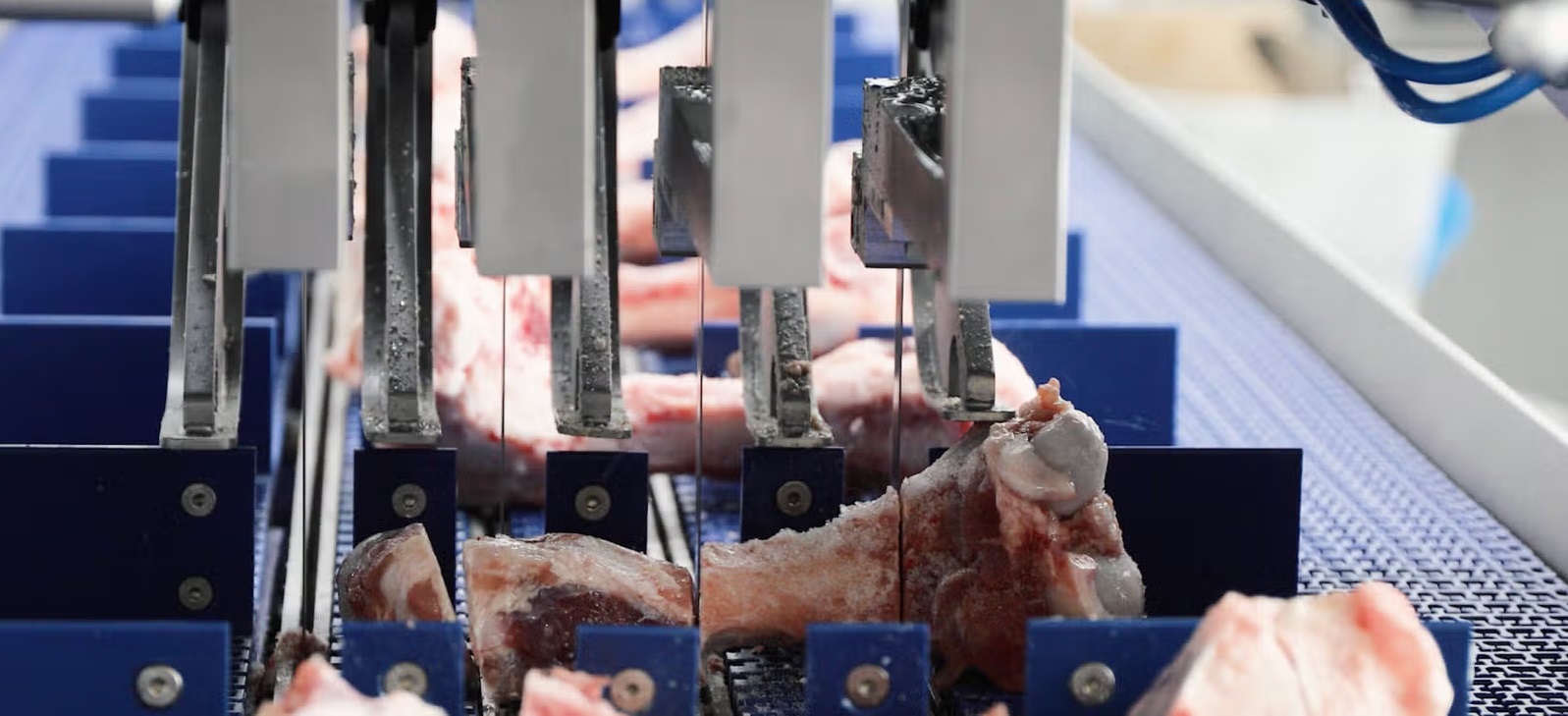

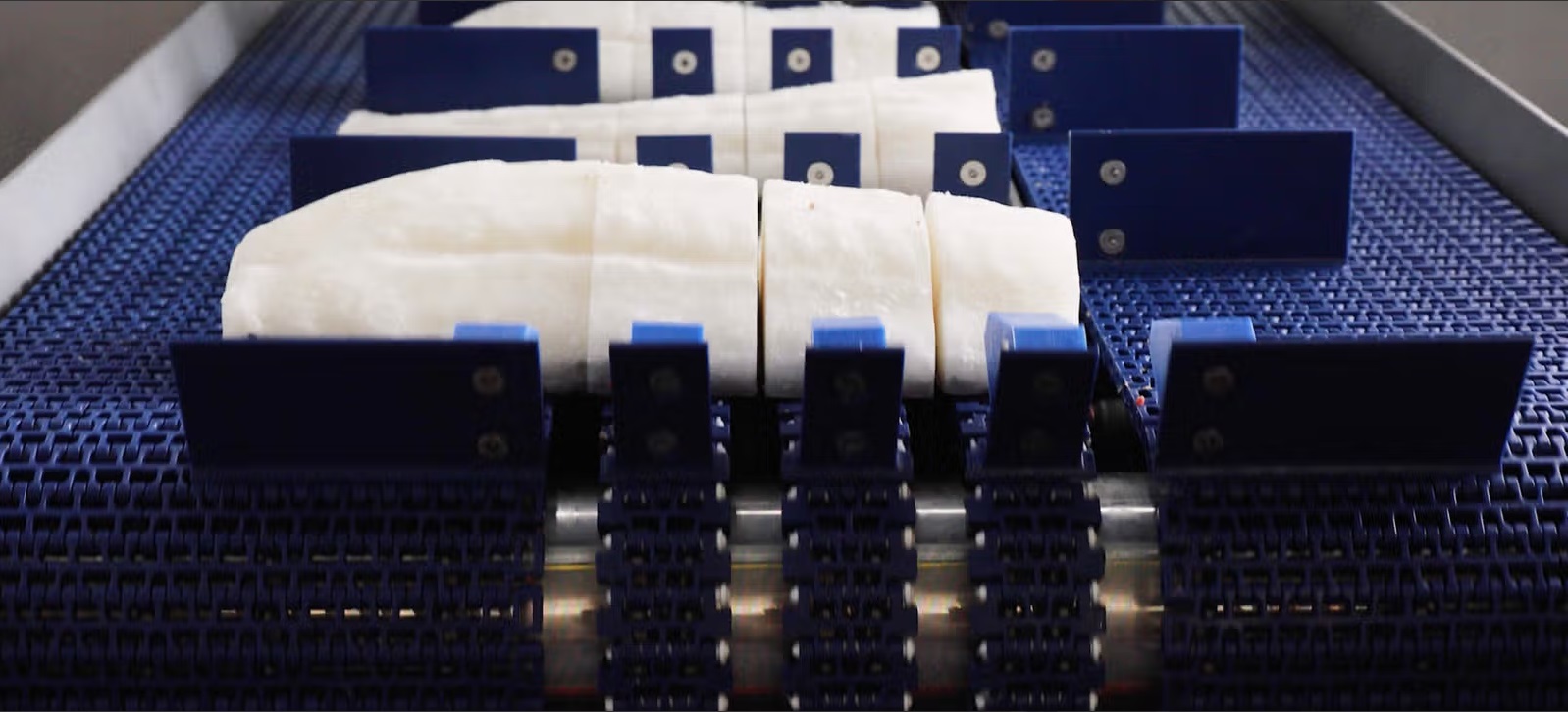

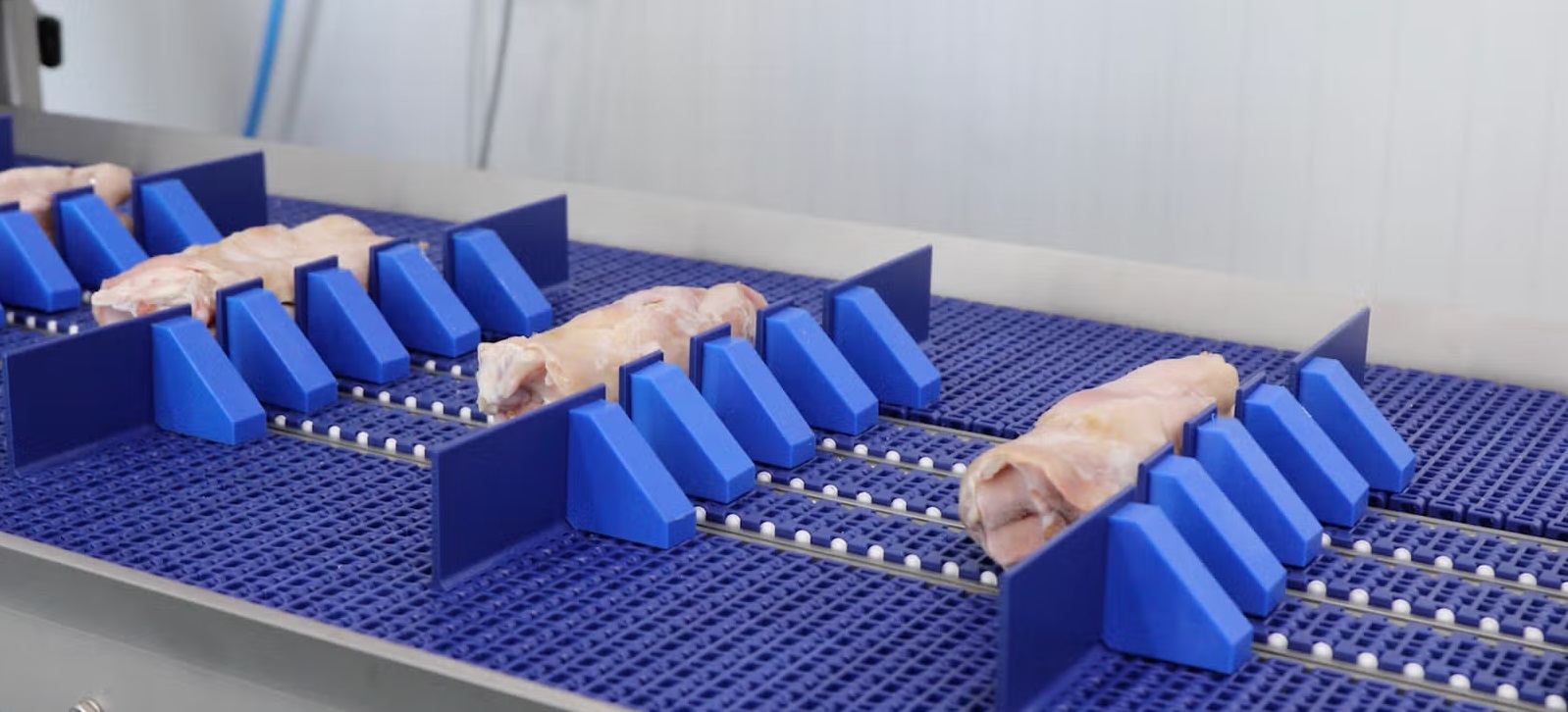

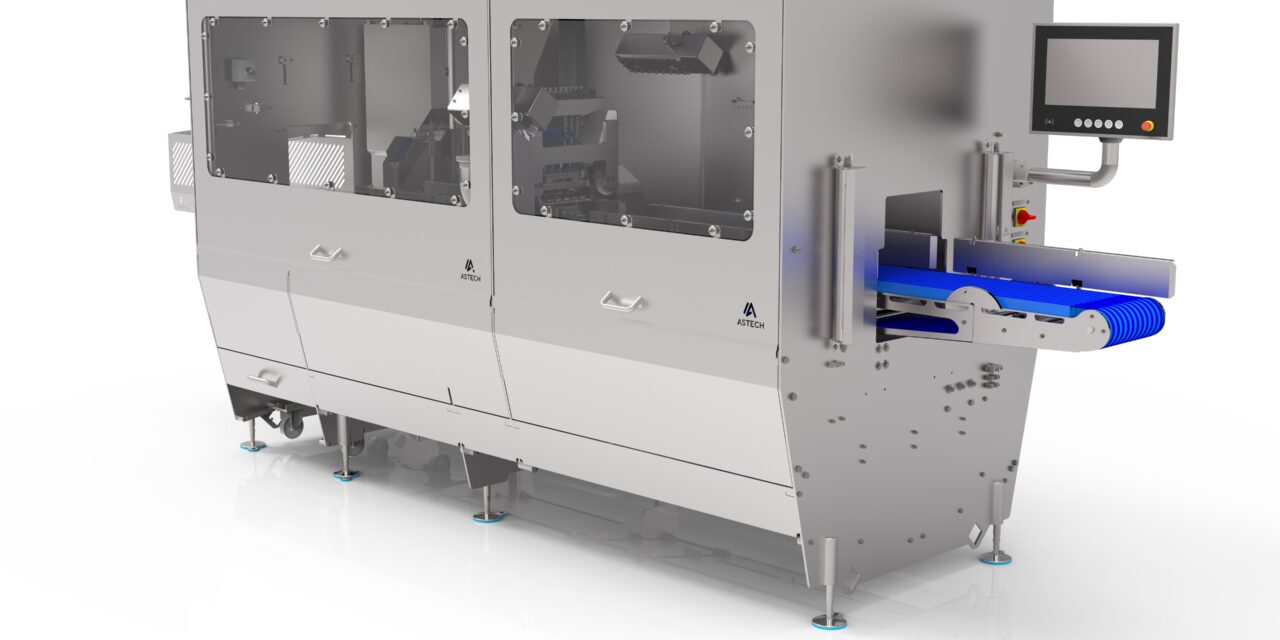

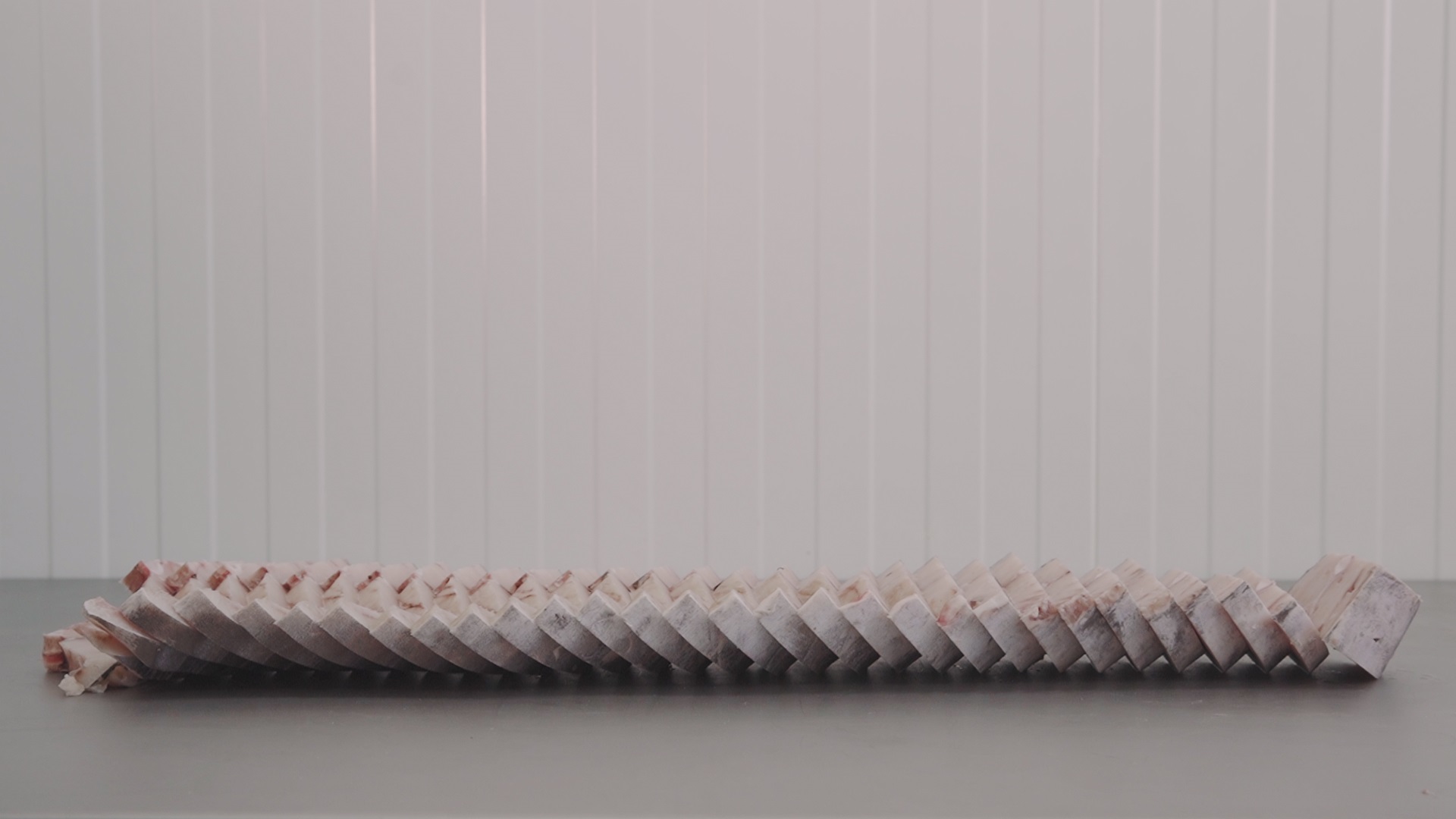

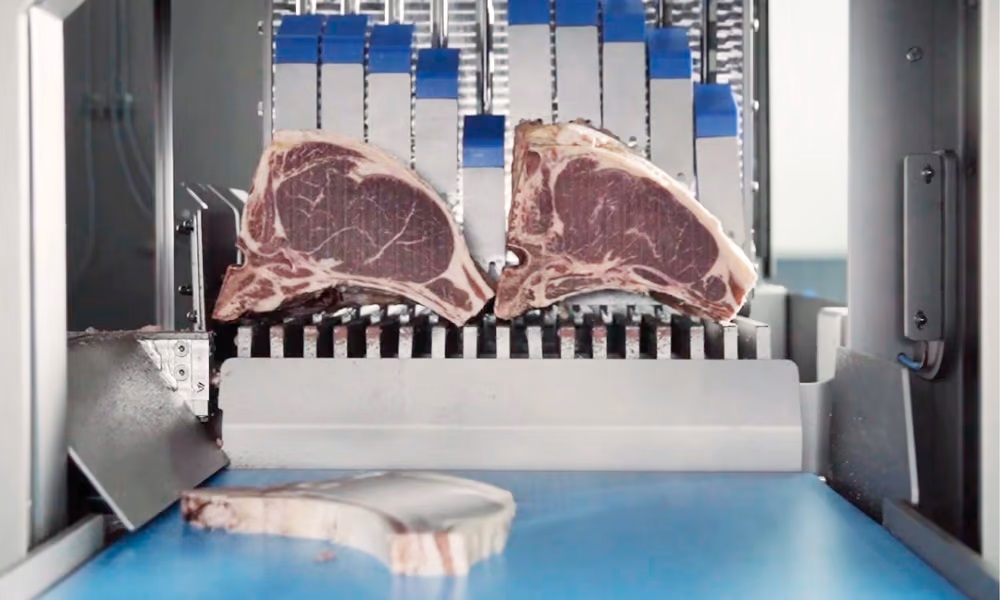

For the longitudinal cutting of products, Astech has designed the Continuous Cutter CC2. The machine makes a longitudinal cut (centered or uncentered) along a chosen product such as pig’s feet, beef legs, knuckles, blocks, etc. The CC-2 cutting machine is loaded manually and the continuous cutting is carried out using a bandsaw in a completely safe process.

Technical specifications

Additional information