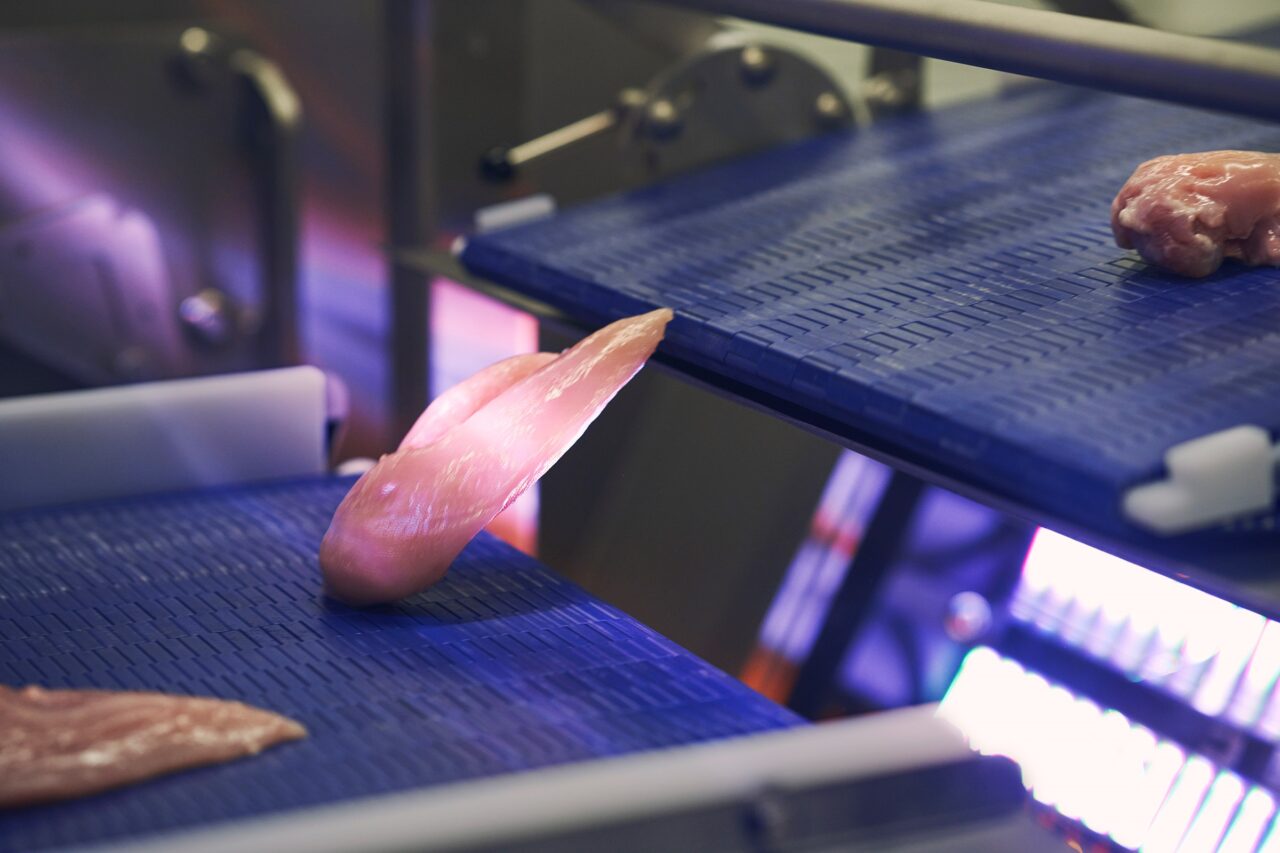

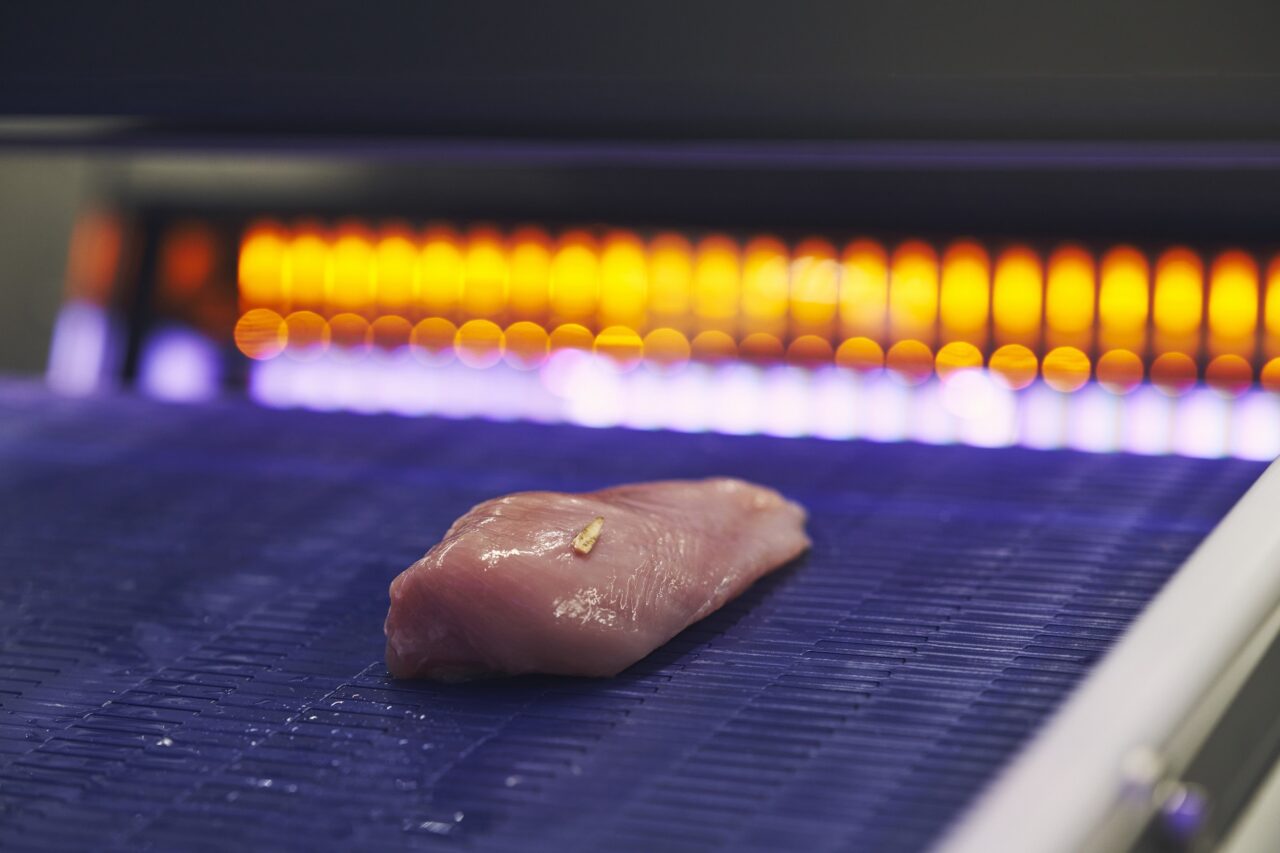

Detection of soft foreign contaminants. Spectra performs a near 360° surface poultry breast fillet scanning, detecting and discarding fillets containing surface contaminants with great effectiveness and precision.

Special Features

Additional information