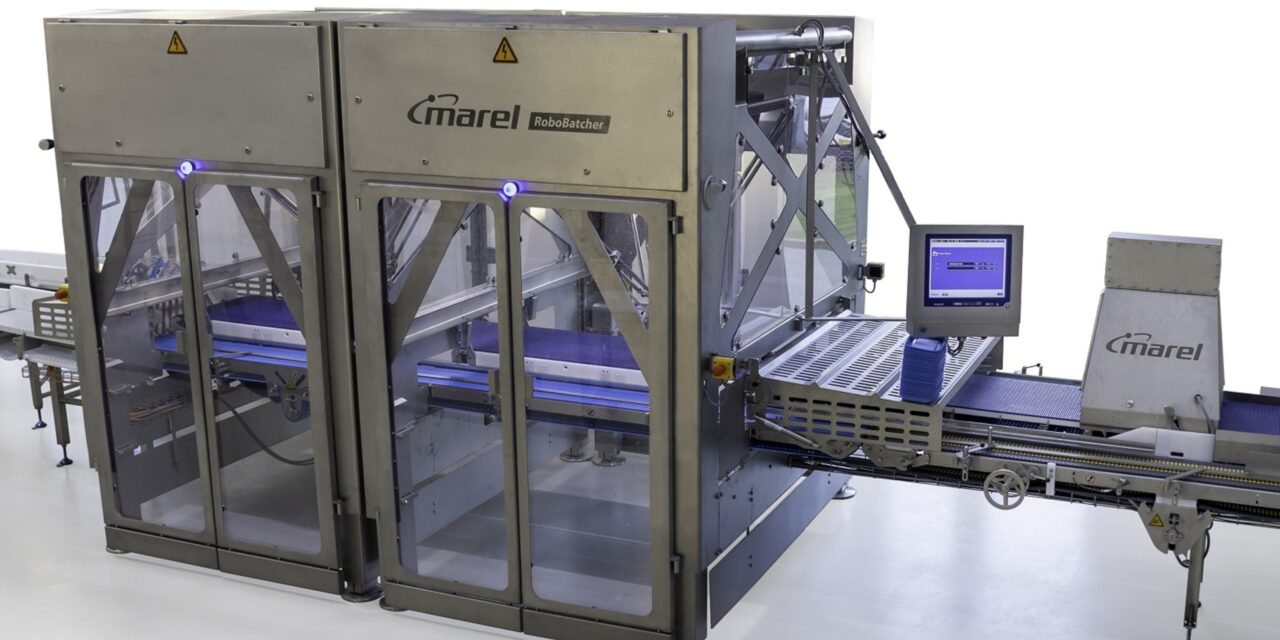

Marel RoboBatcher

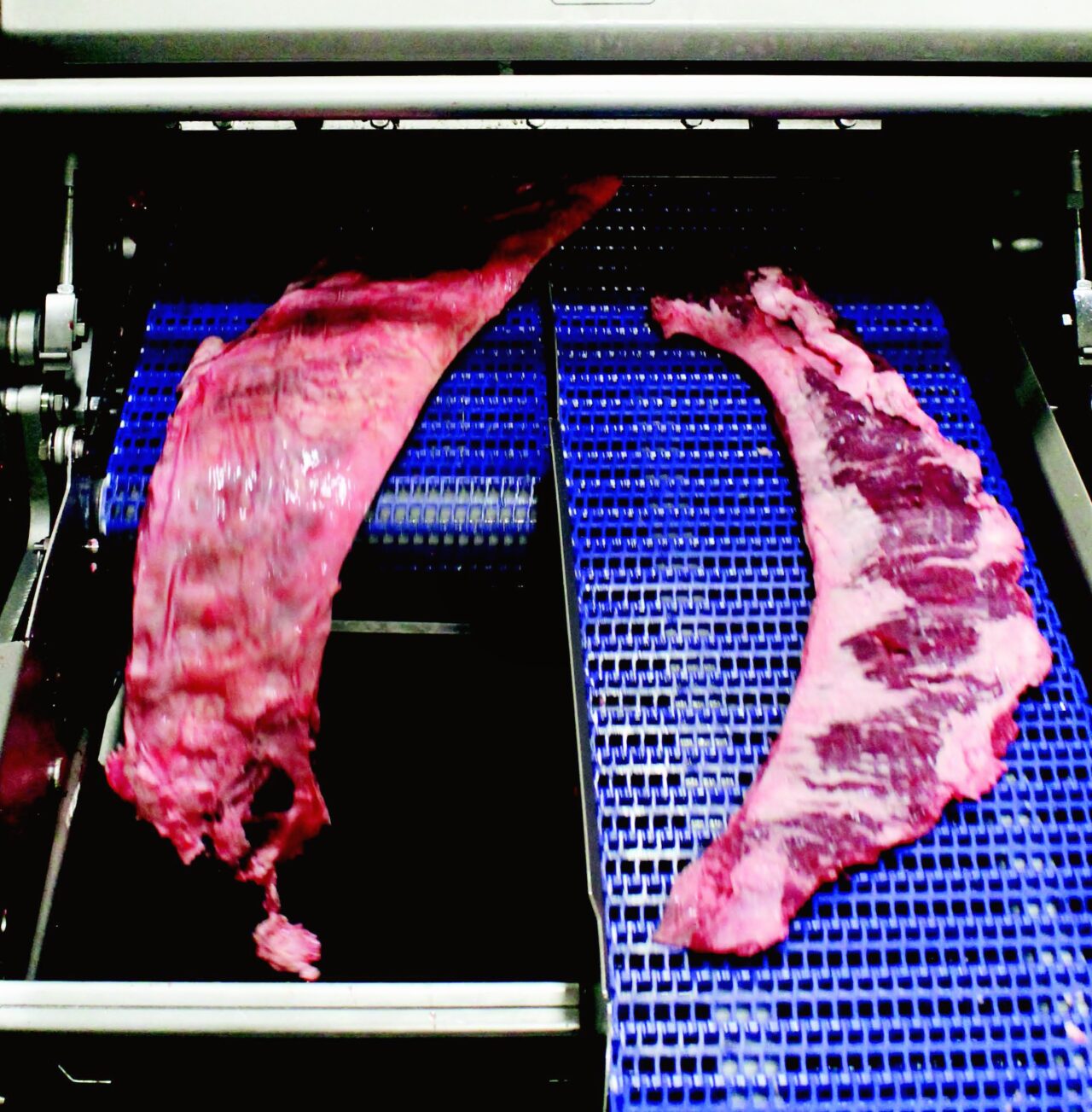

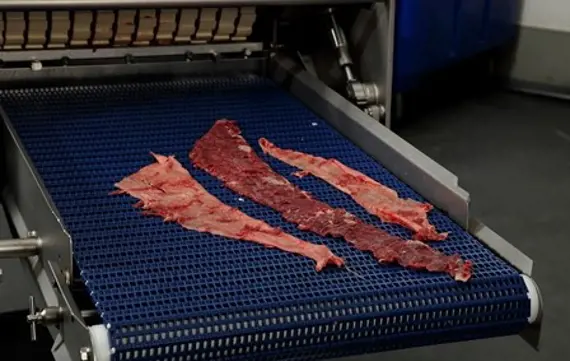

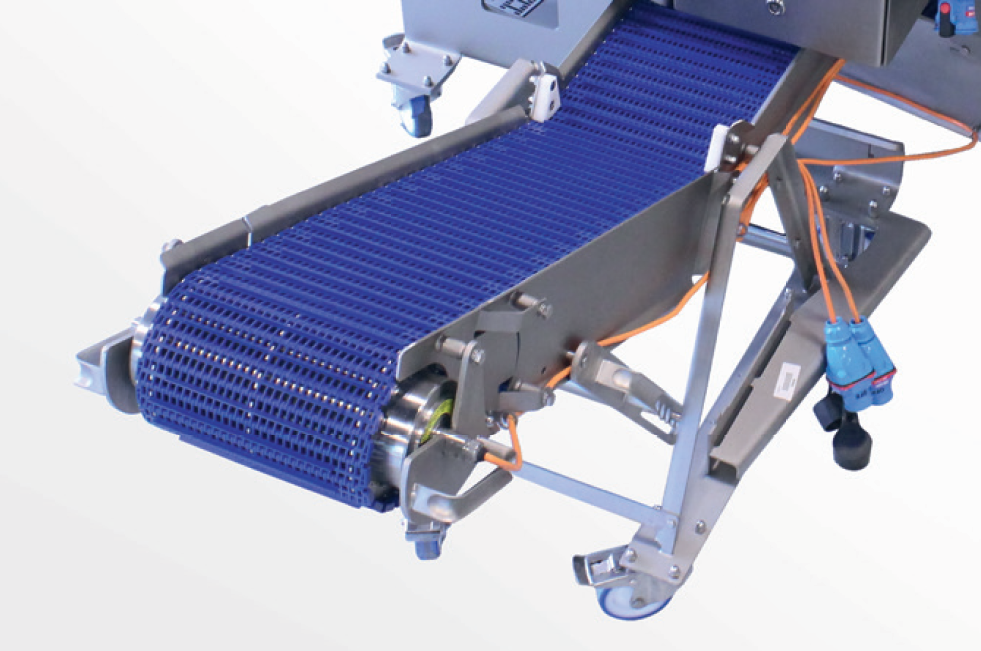

Innovation robotic technology combined with state-of-the-art batching software to pack trays to a fixed-weight virtually eliminating giveaway. Meat, poultry and fish products are scanned and weighed on the RoboBatcher Flex. Robotic arms select pieces using these precise measurements to pack each tray to the pre-programmed fixed-weight and style. Any pieces out of spec can be by-passed, improving quality control and yield.

Special Features

Additional information