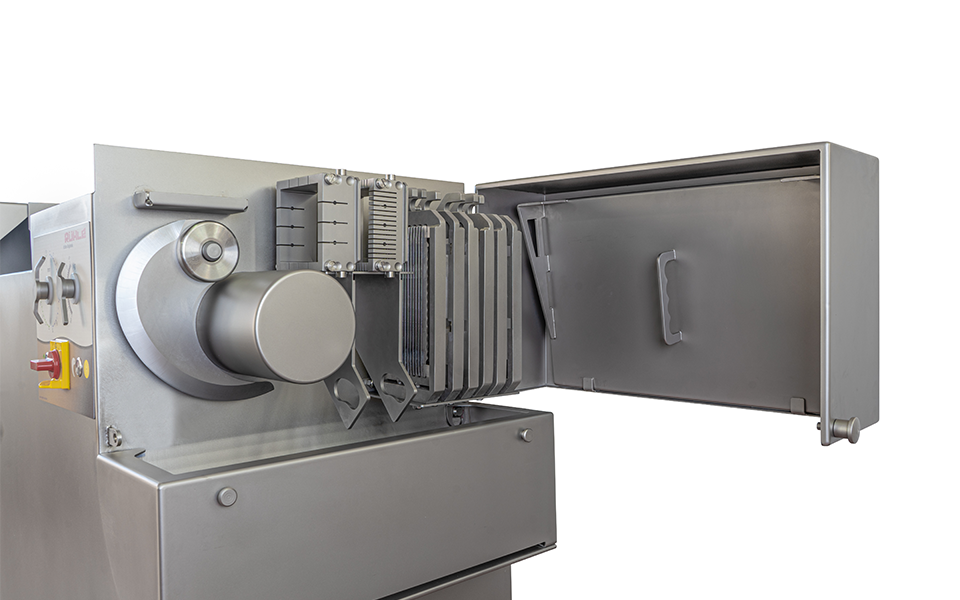

Cutting machine suitable for cutting strips, dices and portions.

Special features

- Angled shaft

- Lateral pre-compacting

- Stabilizers for sliced goods

- Pressure- sensitive pre-compacting

- Multiplex

Technical specifications

Dimensions:(LxWxH):

1070/1900 x 690/890 x 1040 mm

Machine weight:

245 kg

Performance:

max. 1700 kg/ h

Dimensions of shaft (LxWxH):

350 x 100 x 100 mm

Section length:

0,5-60 mm

Sections:

200 per minute

Cutting temperature:

-5°C – +80°C

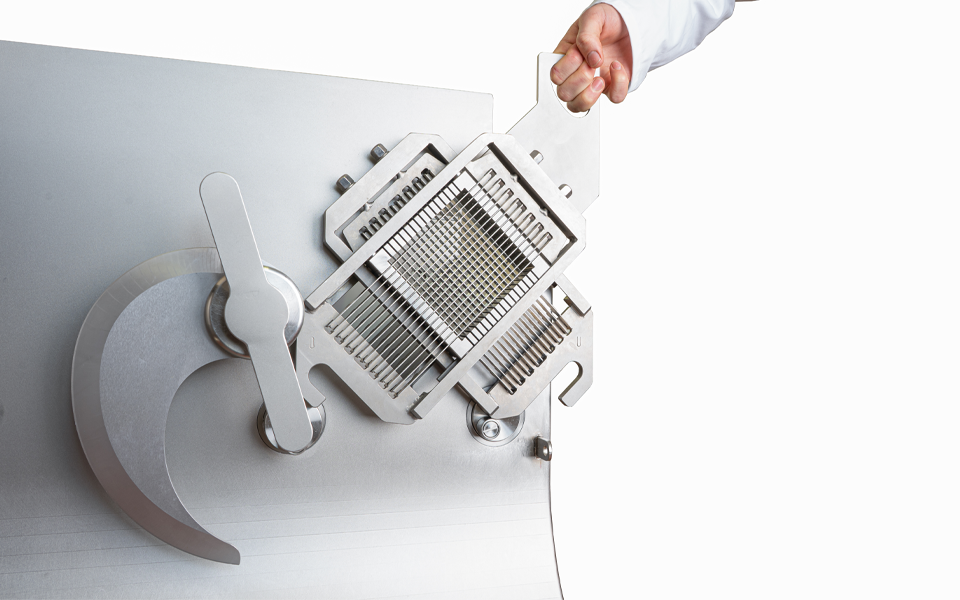

Standard grid sizes:

3, 5, 6, 8, 10, 12, 15, 16, 20, 24, 30, 50

Additional information