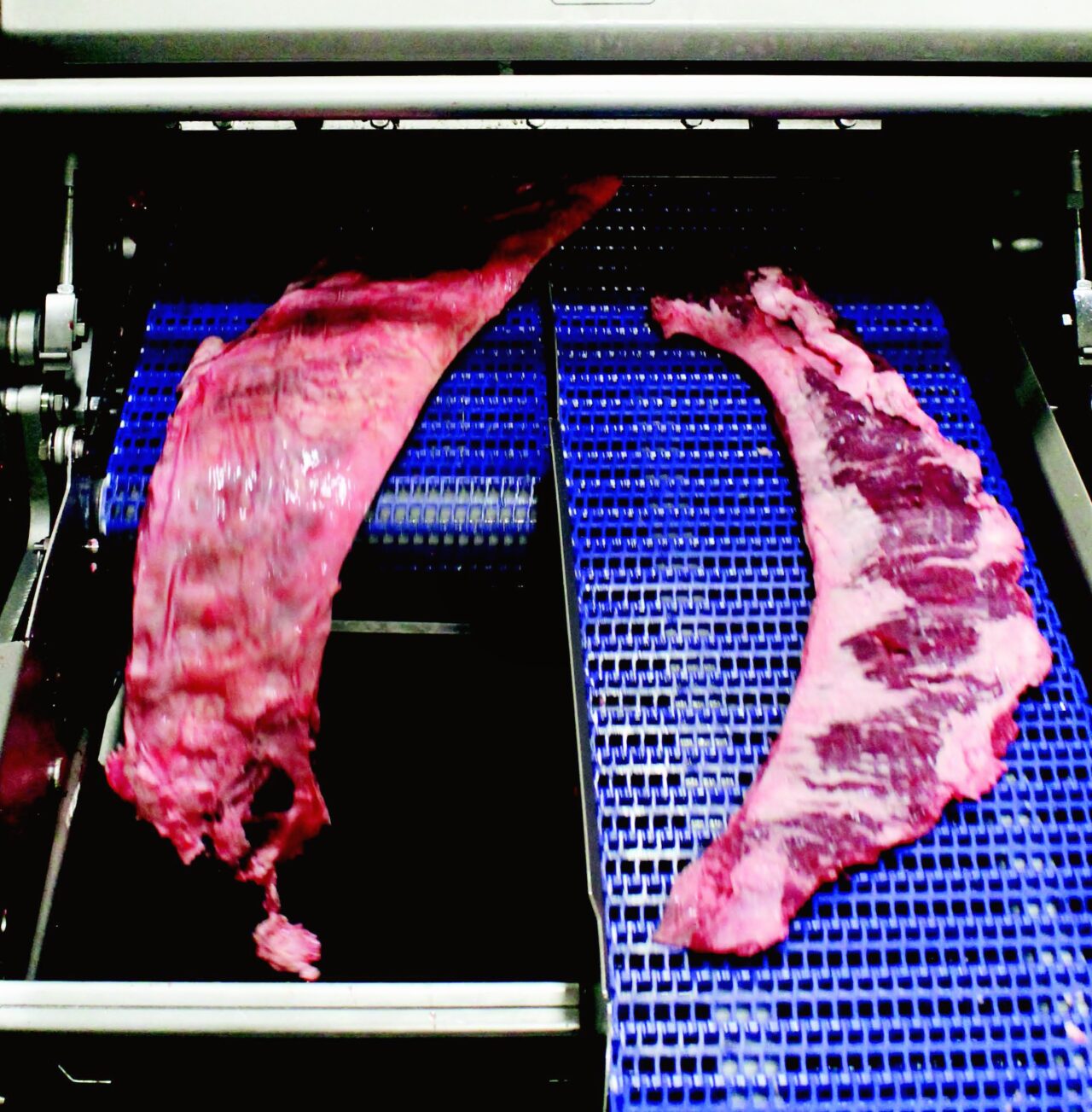

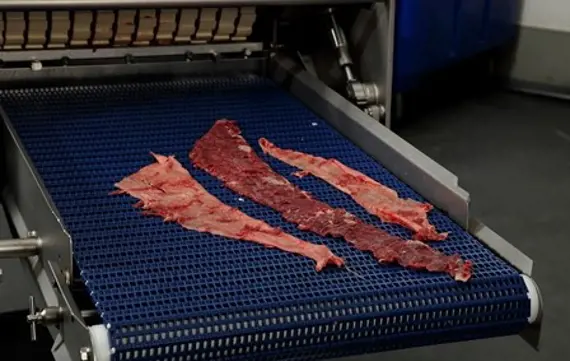

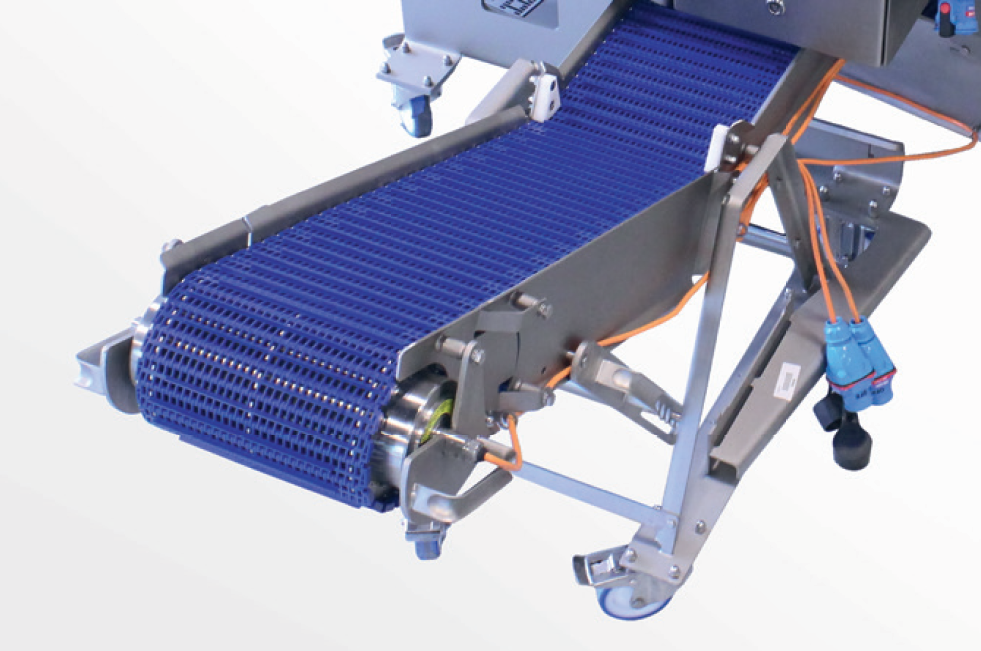

The Townsend SK 14-410 conveyorized skinner has been specifically designed to work on membrane removal in meat applications and it can be configured accordingly to ensure the highest yields and throughput possible while providing reliable skinning results.

Special features

Additional information