The degutting systems from Makelis are made entirely of stainless steel and food-grade plastic materials. Depending on the demand and production requirements, each degutting system is designed and manufactured individually.

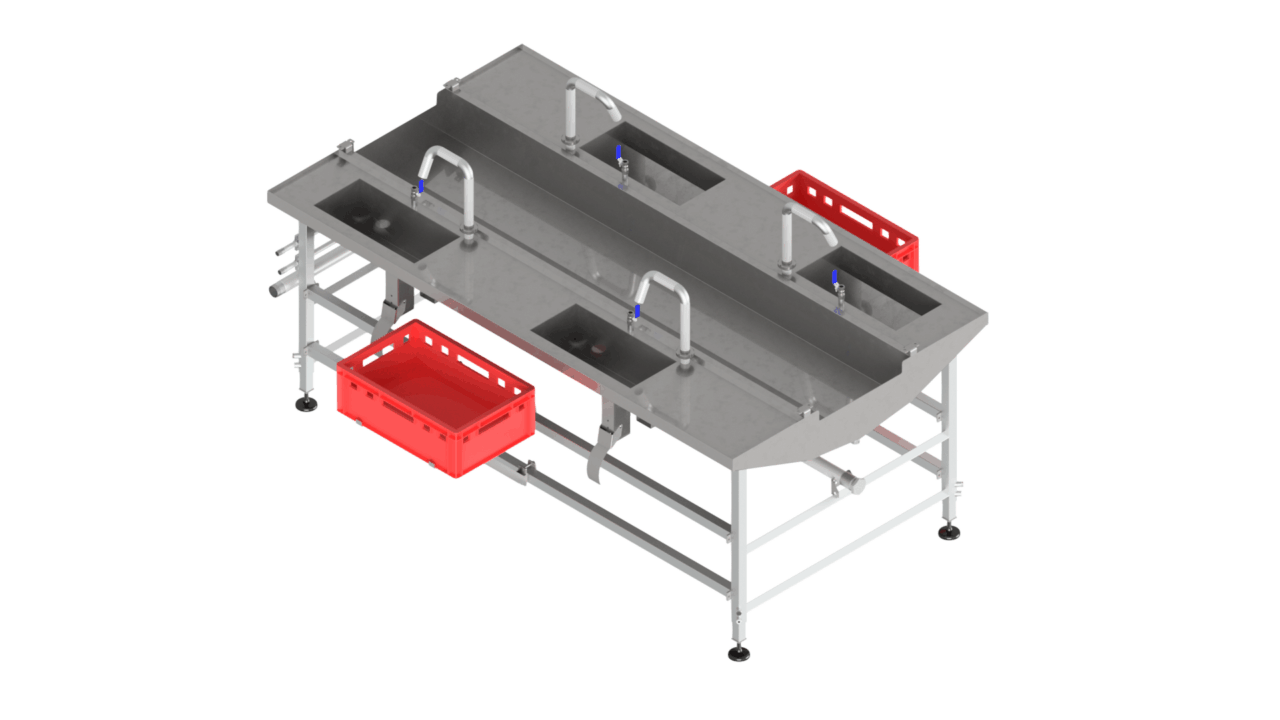

Model with central tank

The fish are placed in a central basin with water and each side has work stations.

Upon receiving the fish, each worker places the fish in the special nozzle and by pressing a button at knee height, activates the vacuum system. In this way, the entrails are removed from the fish.

Each station has a tap with running water, a sink, a processing bench and a vacuum nozzle.

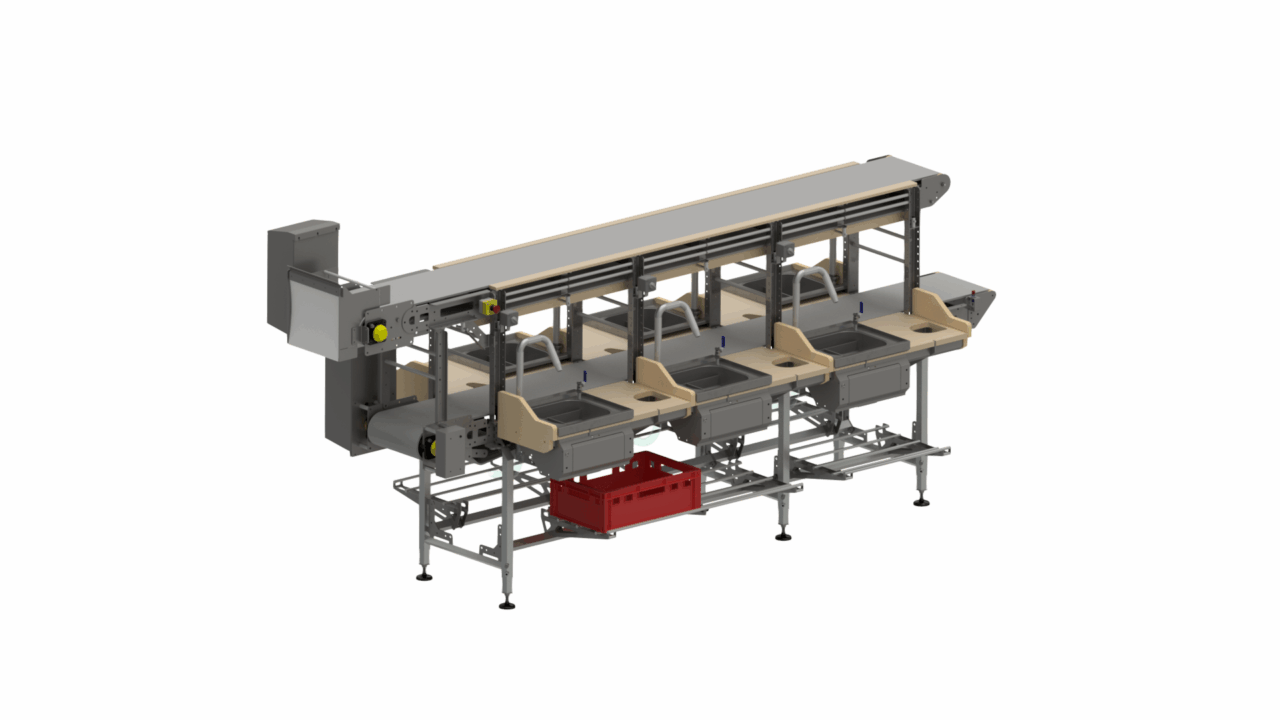

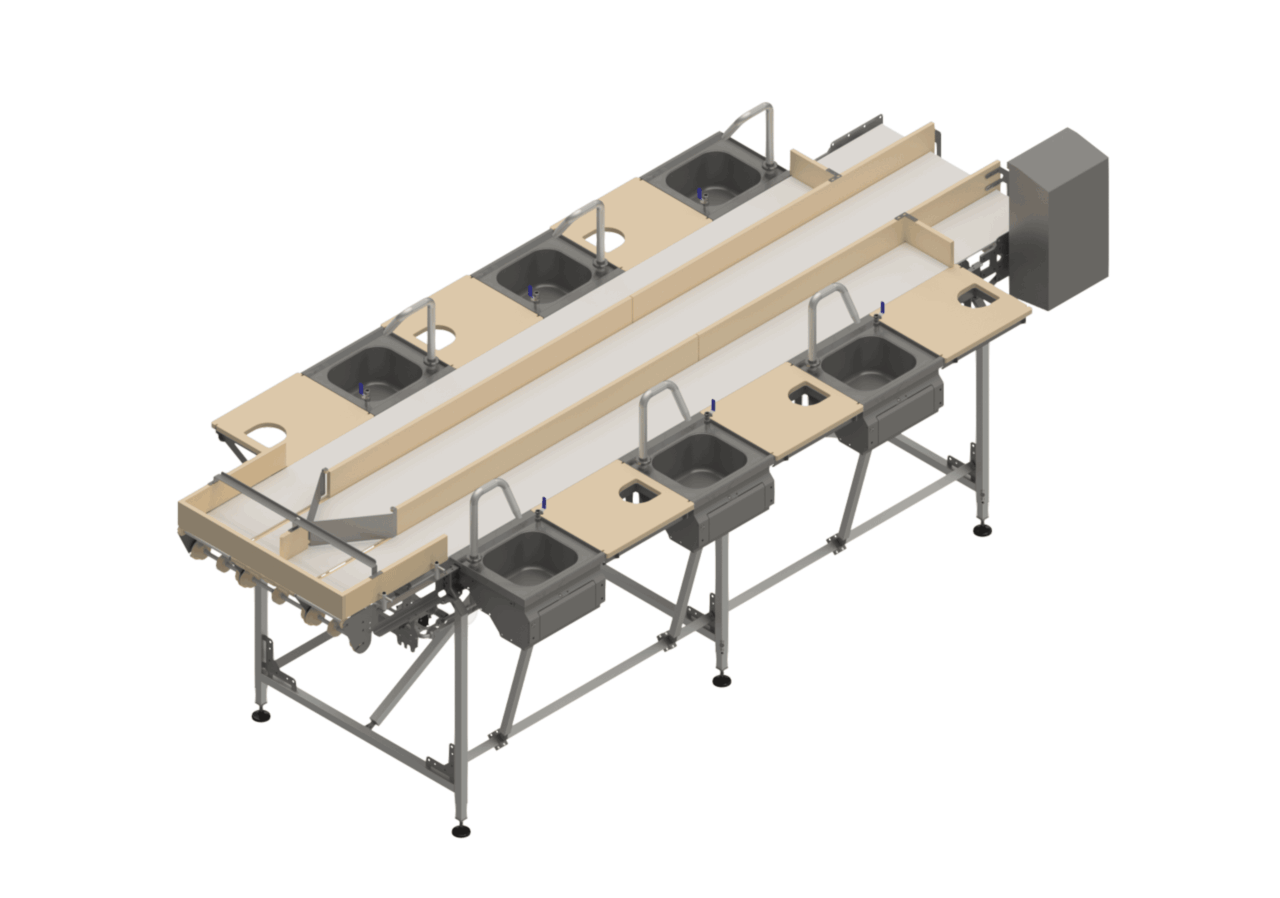

Model with conveyor belt system

The system features a belt connected system suitable to receive the fish in a main area and forward them automatically in front of the working areas.

Each side consists of plastic tables with sinks, vacuum nozzles and water taps. The operators receive the fish, then they manually gut the fish with the vacuum nozzle, then washes the fish with the use of the water tap and the sink and in case that they remove pieces with a knife they put them inside the crates with the use of a hole. After the processing is done the operator manually positions the finished fish in the center of the conveying system to automatically forward it outside of the system.

Special Features

- Manufactured from stainless steel AISI304 and plastic materials suitable for the food industry

- Electrical control panel

- Vacuum pump of high performance

- Control system of the pump for energy saving

All the machines and the constructions of Makelis are customized to each individual need.