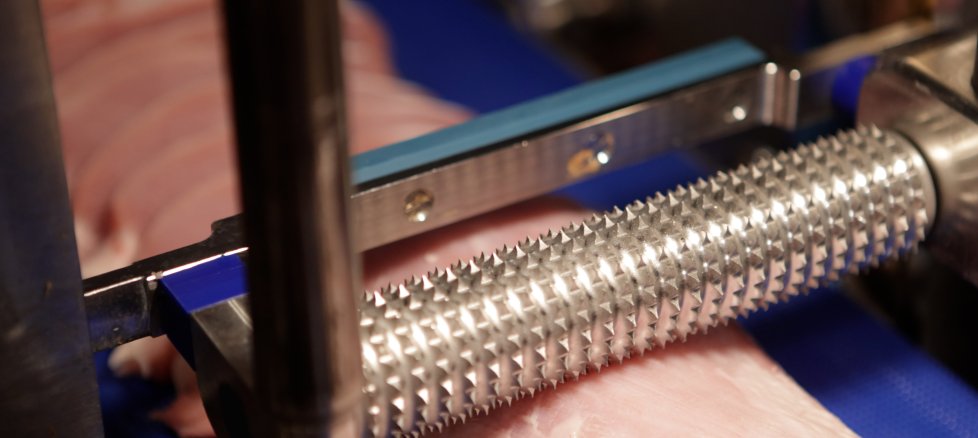

AVITOS confidently cuts frozen meat, such as bacon cubes or strips, at a product temperature of down to -18°C without any prior cutting.

Special features

- Cutting blocks of frozen meat, calibrated goods etc. at down to -18°C

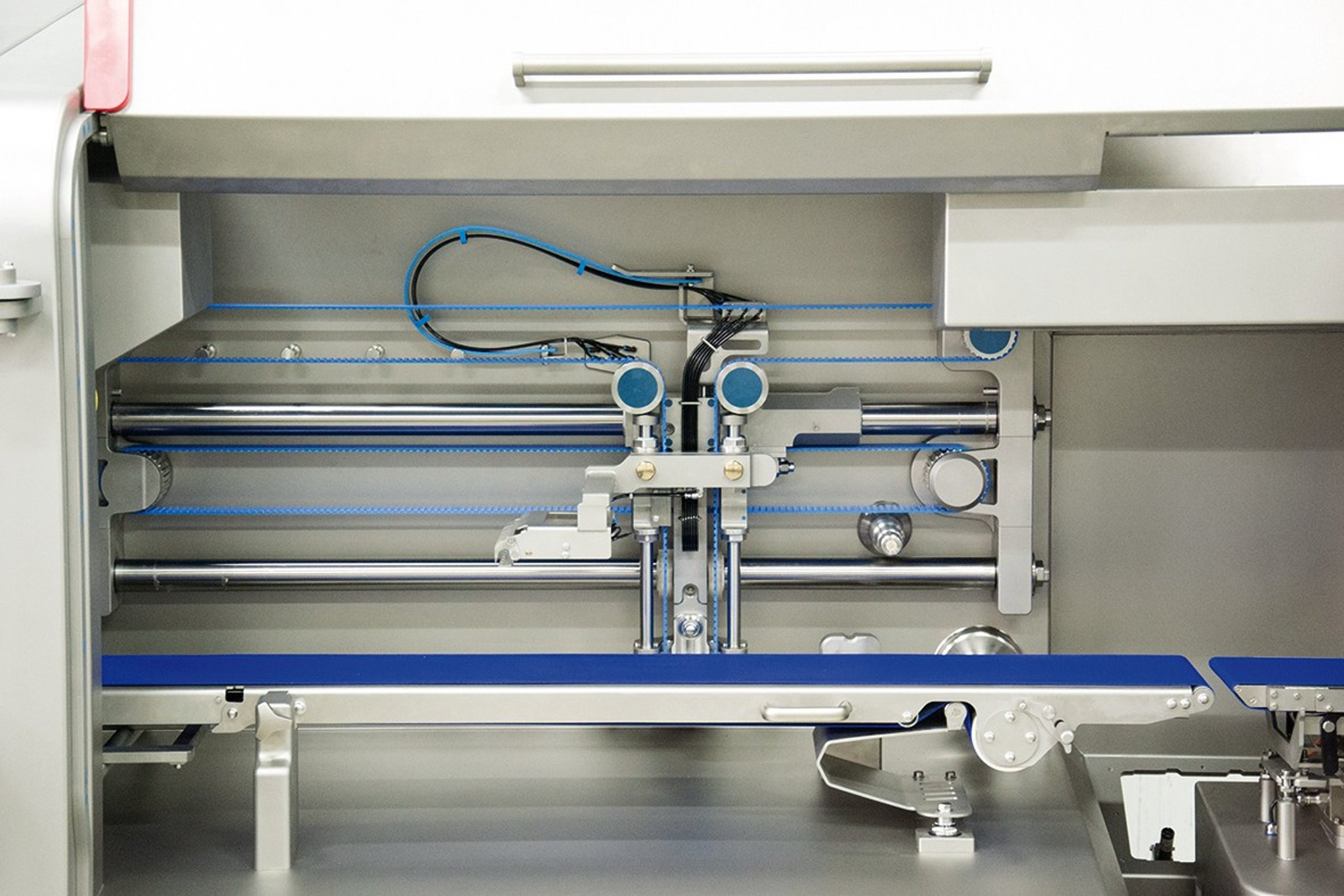

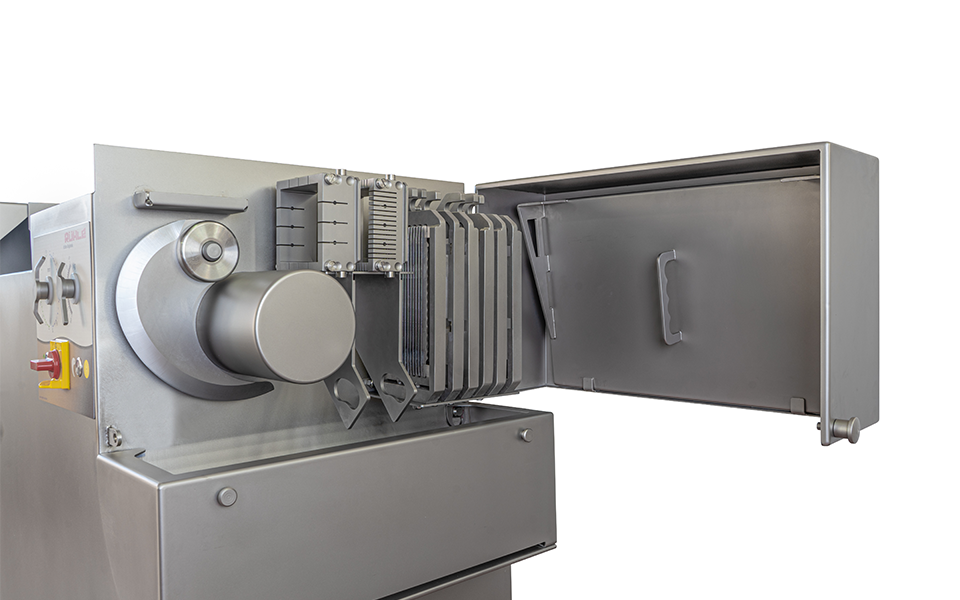

- Top cutting pattern/ optimal product guidance

- No pre-cutting: maximum efficiency and operator safety

- Loading via conveyor belt to hoppe r or manually

- No change of product temperature for the cutting process

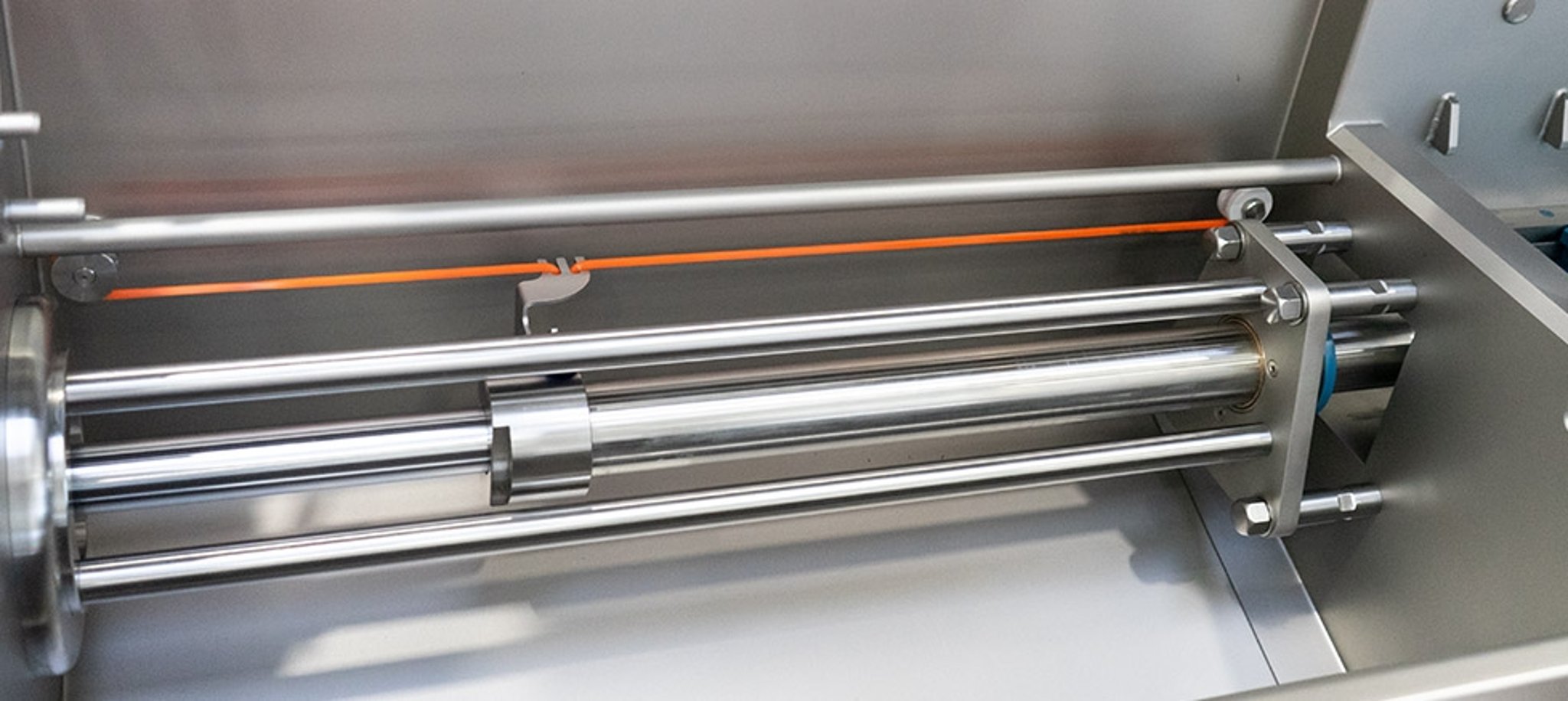

- Hygienic design

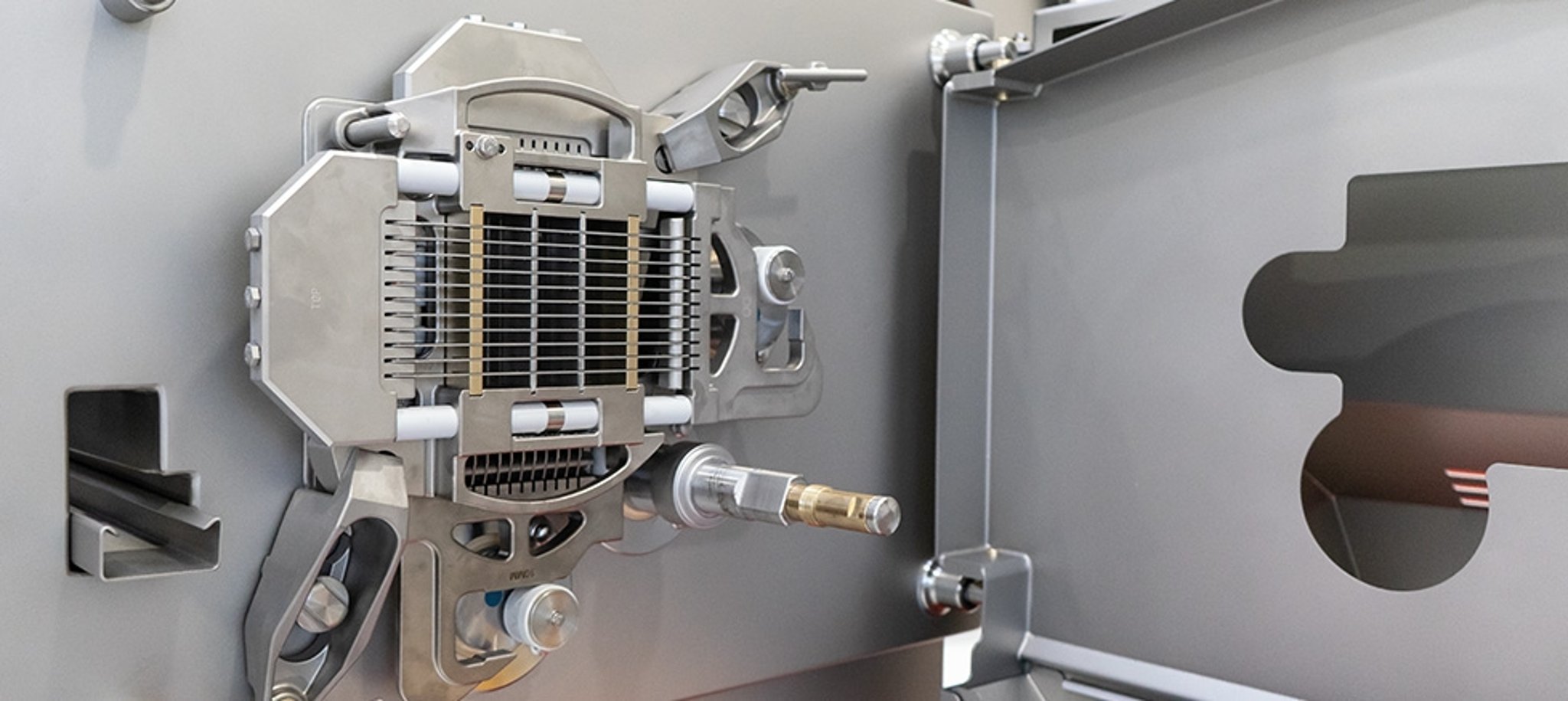

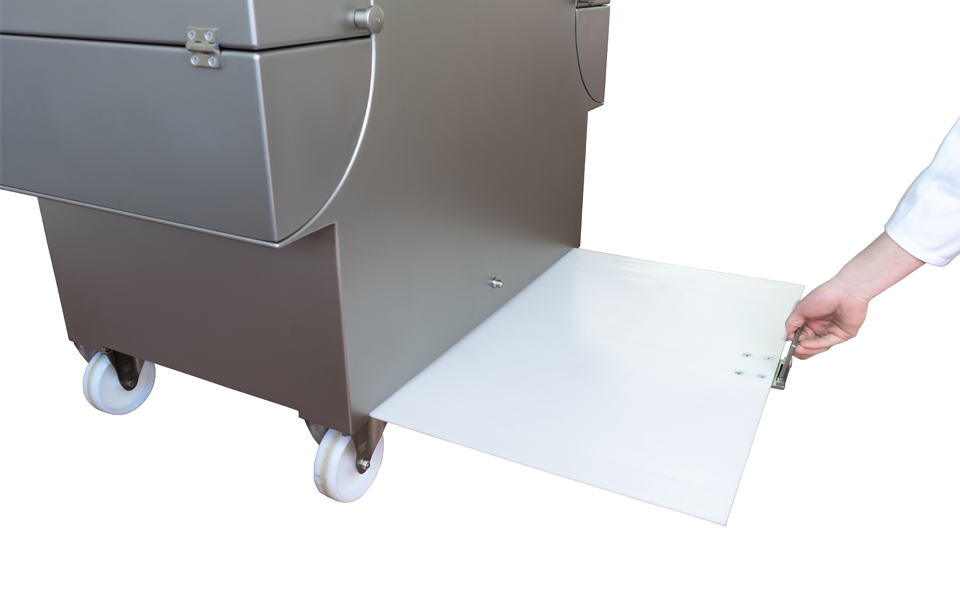

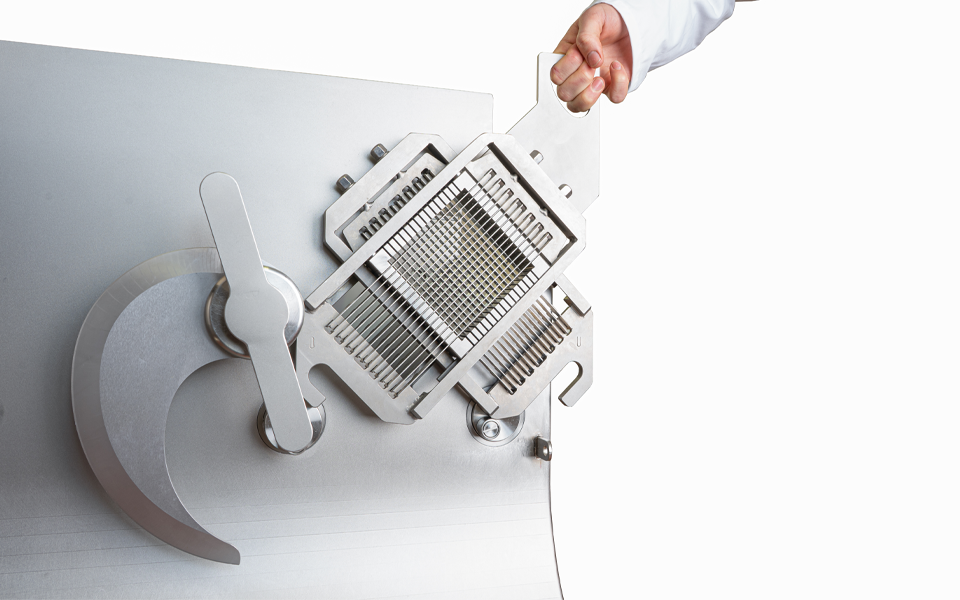

- Safe and simple change of the cutting tools due to tool changing cart

- Different discharge variants

- Rotatable display, USB port, remote maintenance

Technical Specifications

| Max. output | 2.0 tons per hour |

| Cutting chamber size (WxH): | 210×620 mm |

| Max. cut-off length | 620 mm |

| Cross-section of product (WxH) | 120×150 – 200 mm |

| Housing dimensions | |

| Standard length | 3511 mm |

| Width with conveyor belt/ with manual loading: | 5241/2691 mm |

| Height with conveyor belt/ with manual loading | 2415/2221 mm |

| Applications | up to -18°C |

Additional information