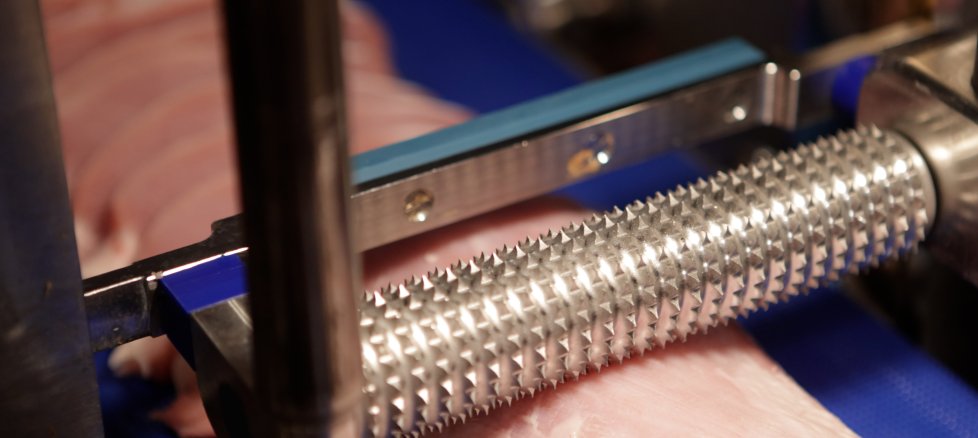

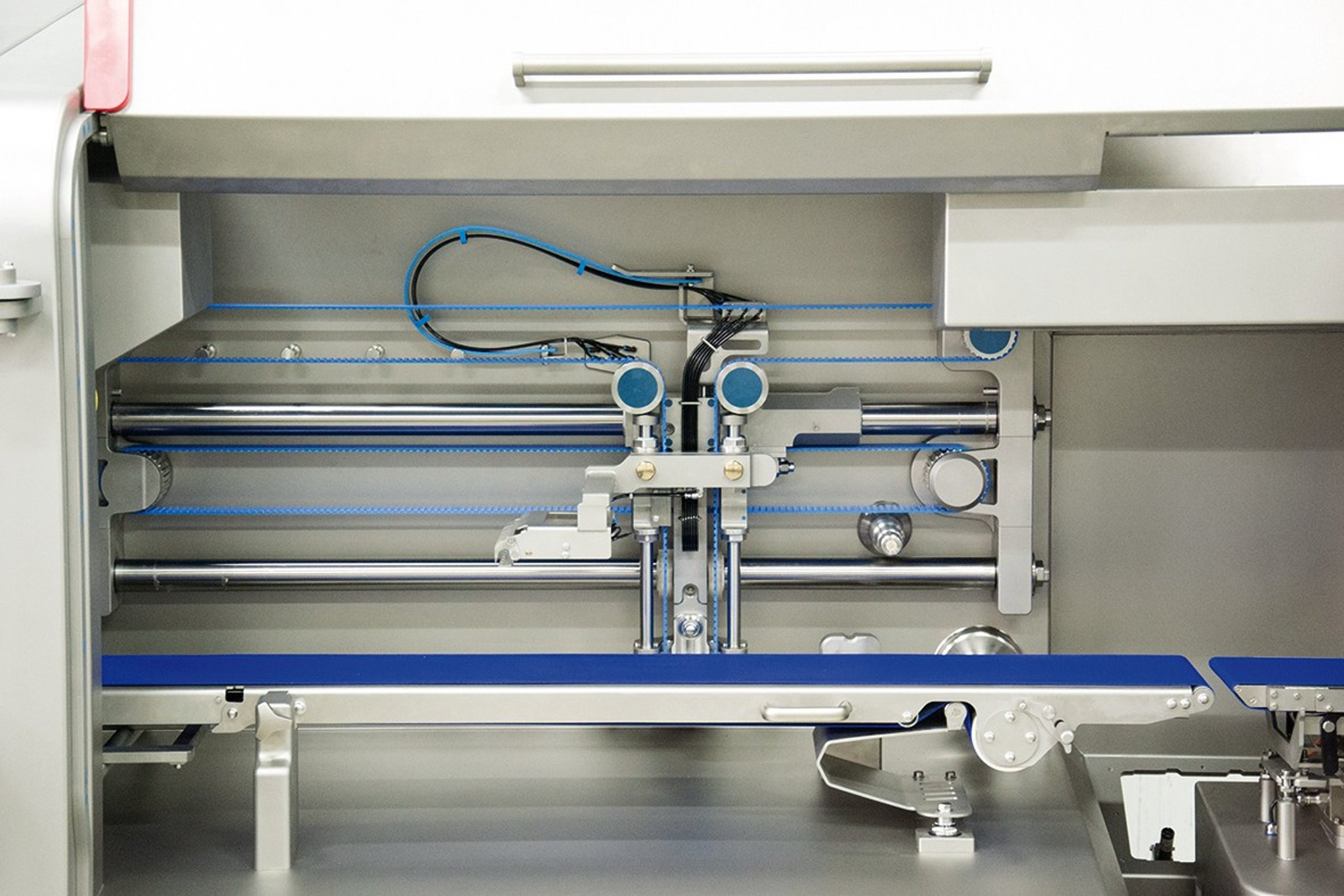

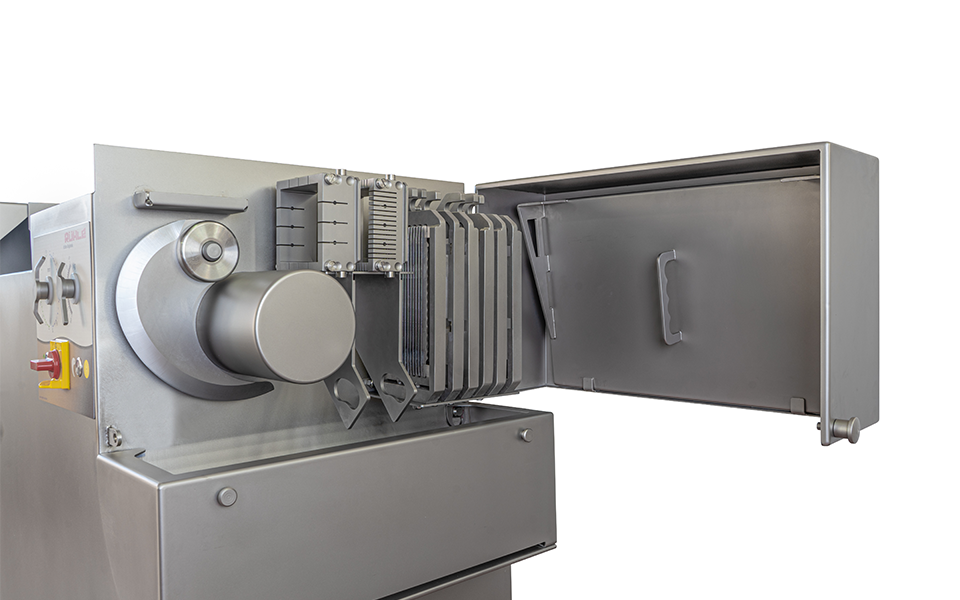

The industrial dicer TWISAN, consistently delivers optimal dicing results, both with frozen meat blocks and bulk material and also with fresh meat.

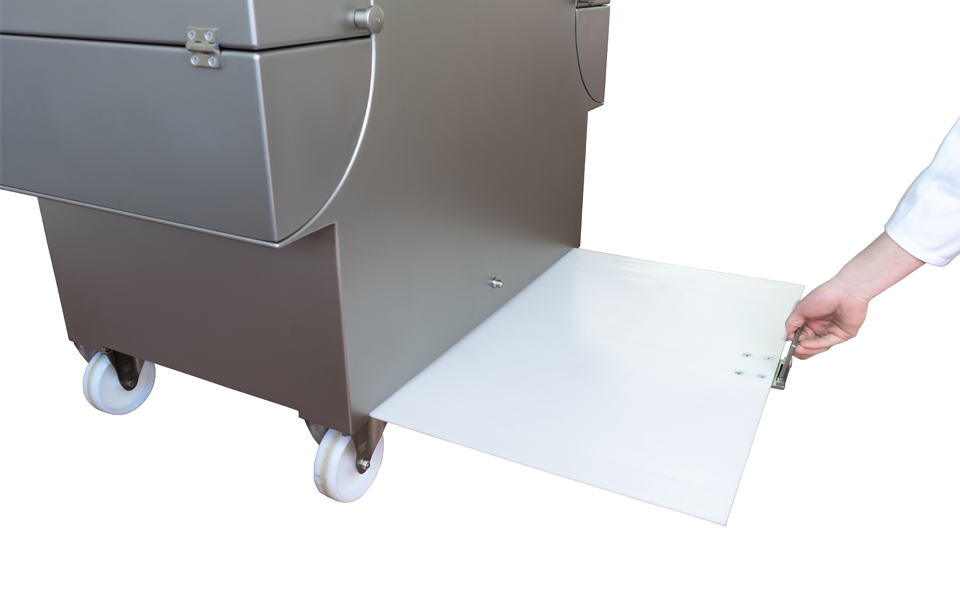

Regarding the fully automatic loading of the machine and discharging of cut products, there are numerous ways in which you can optimally tune the production process.

Technical Specifications

| Max. output |

4.5 tons/hour |

| Max. cut-off length |

1-75 mm |

| Max. blade speed |

400 cuts per minute |

| Cutting chamber size (WxH): |

150×150 mm |

| Max. infeed length |

620 mm |

| Housing dimensions: | |

| Length with conveyor belt/ with lift-tilt-device |

2345/ max. 3600 mm |

| Width with conveyor belt/ with lift-tilt-device |

4660/ max. 3000 mm |

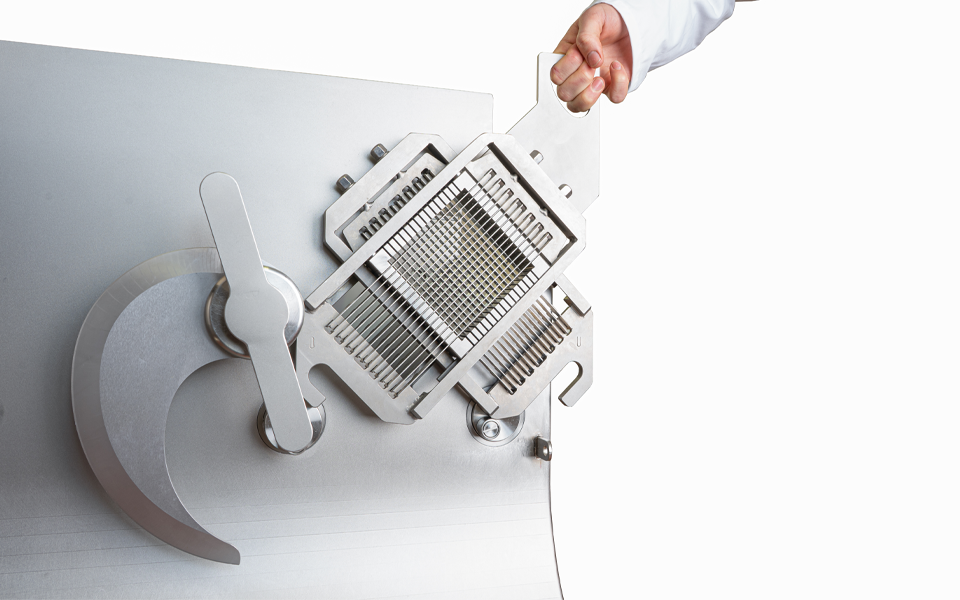

| Gridsets |

8/10/12/15/17/19/21/25/30/37,5 mm |

Additional information