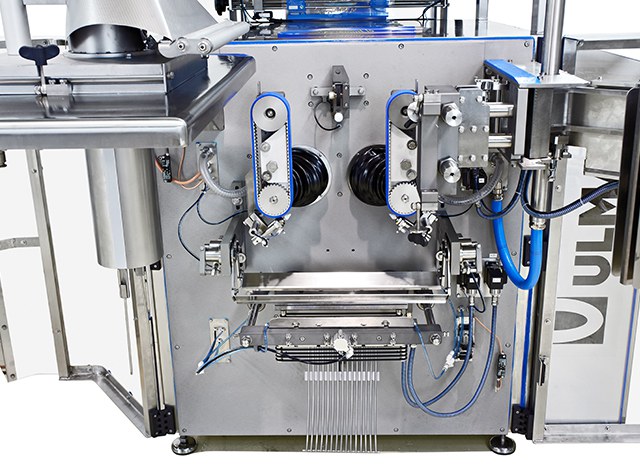

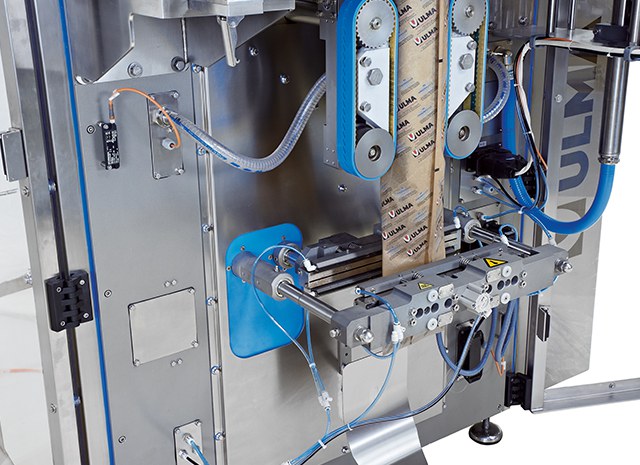

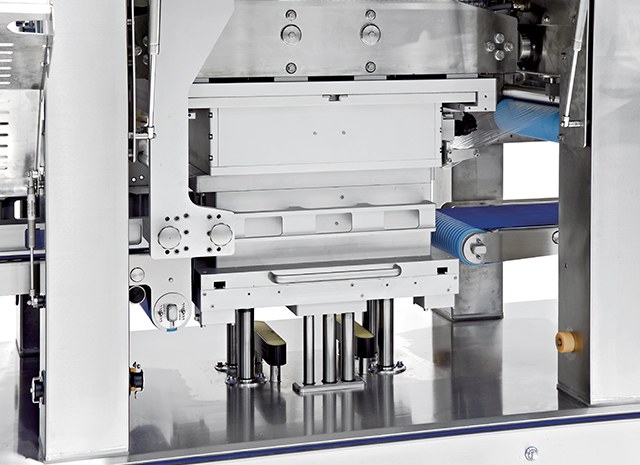

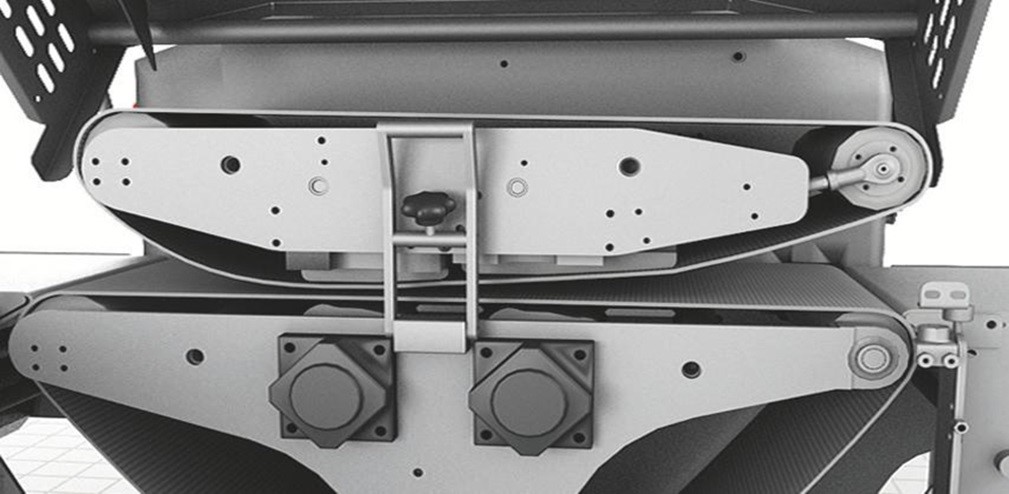

Vertical packaging machine (VFFS) which makes a three sealing pack. . High performance intermitent vertical machine for medium-high speed applications. 50-70 packs per minute.

ULMA’ s new family of vertical machines has been devised with and for customers. The optimised work performance and new features of the machine help to obtain the best production rates with the highest quality container.

Special features

- Hermetic design, prepared for harsh environments and demanding cleaning processes

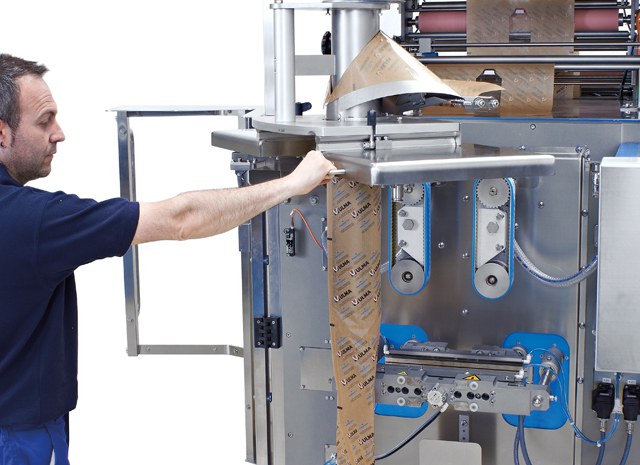

- Ergonomic design

- Possibility of changing format on one side: practical, safe, ergonomic and simple

- Control by 10″ industrial PC touch screen

- Easy to use for the machine operator: simplified daily adjustments without tools.

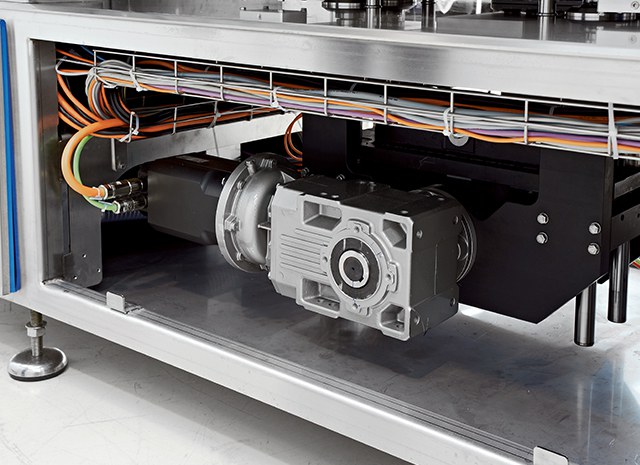

- Low maintenance costs

Additional information