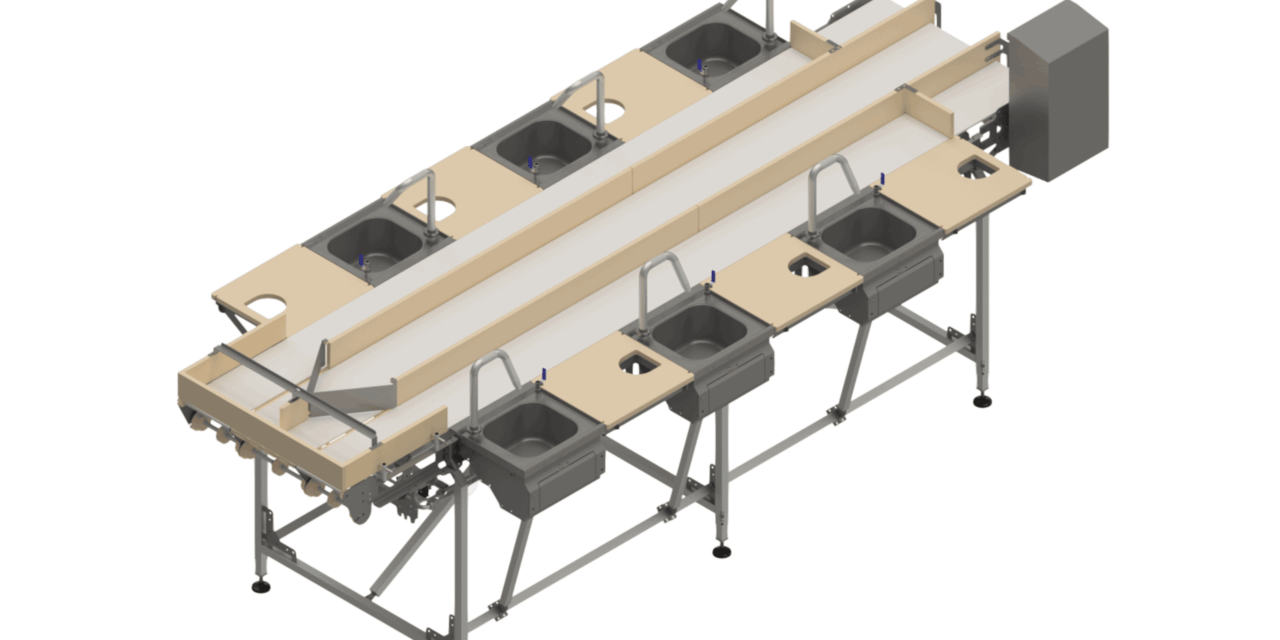

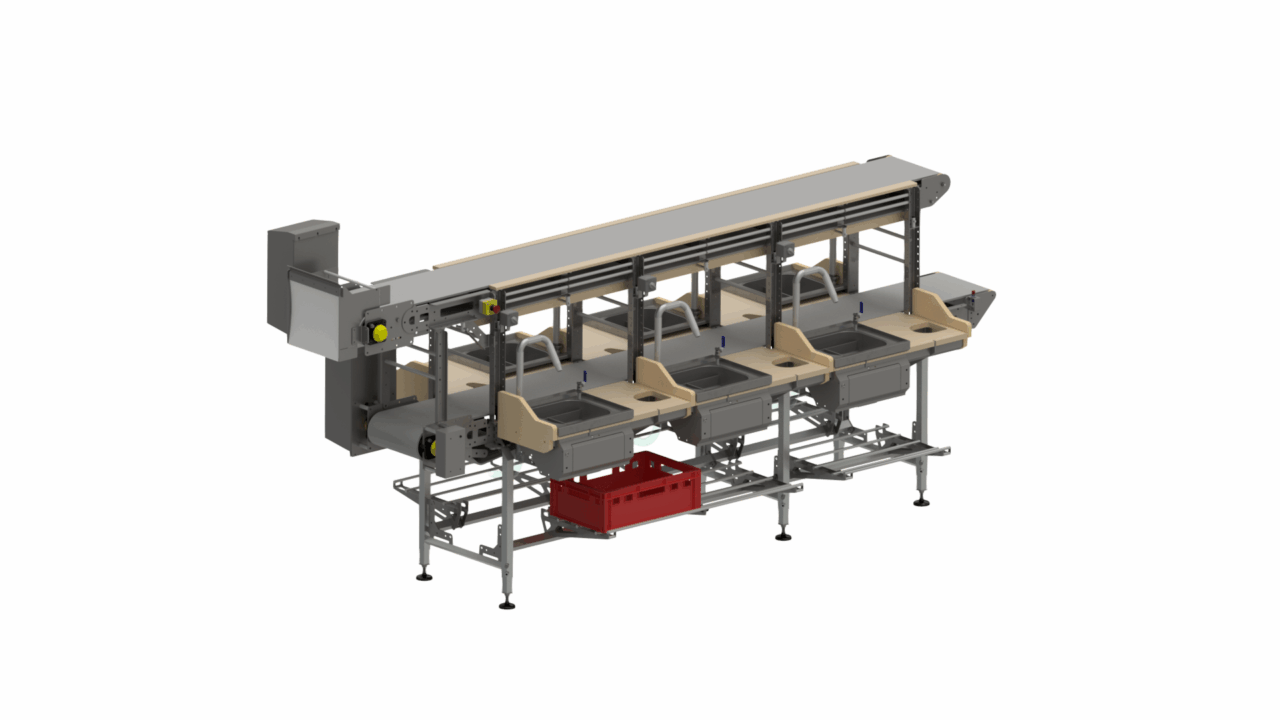

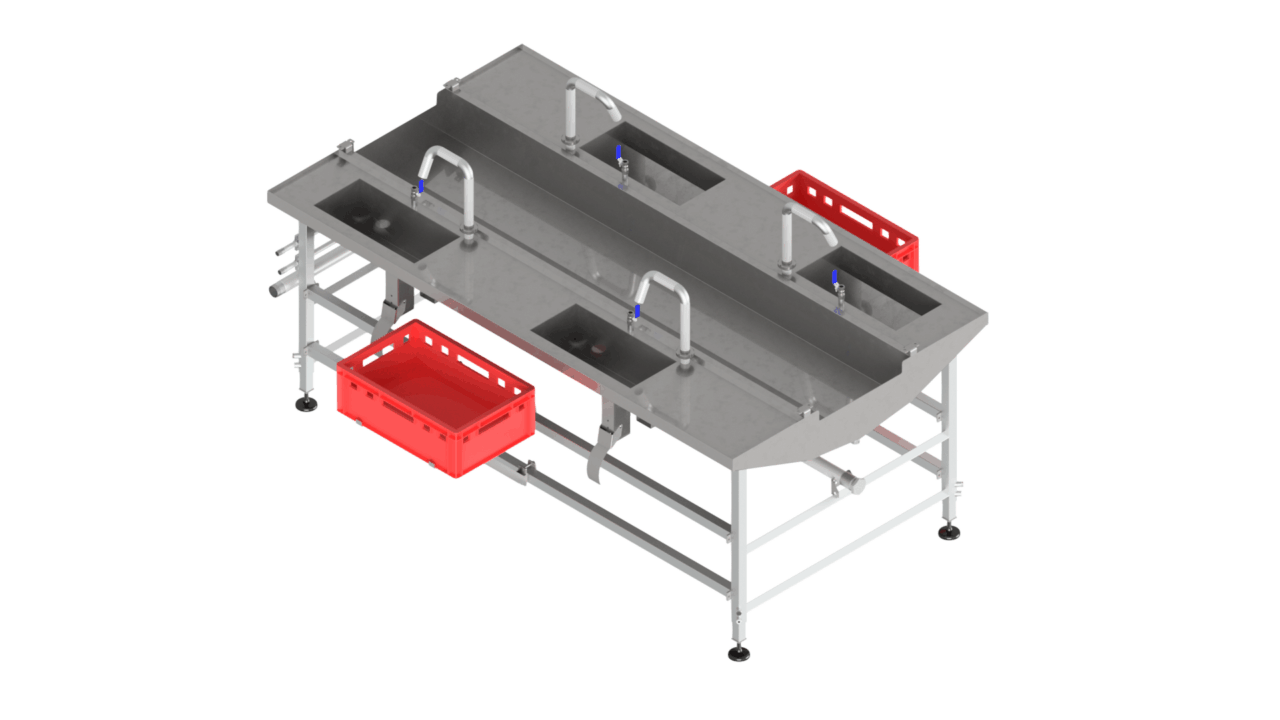

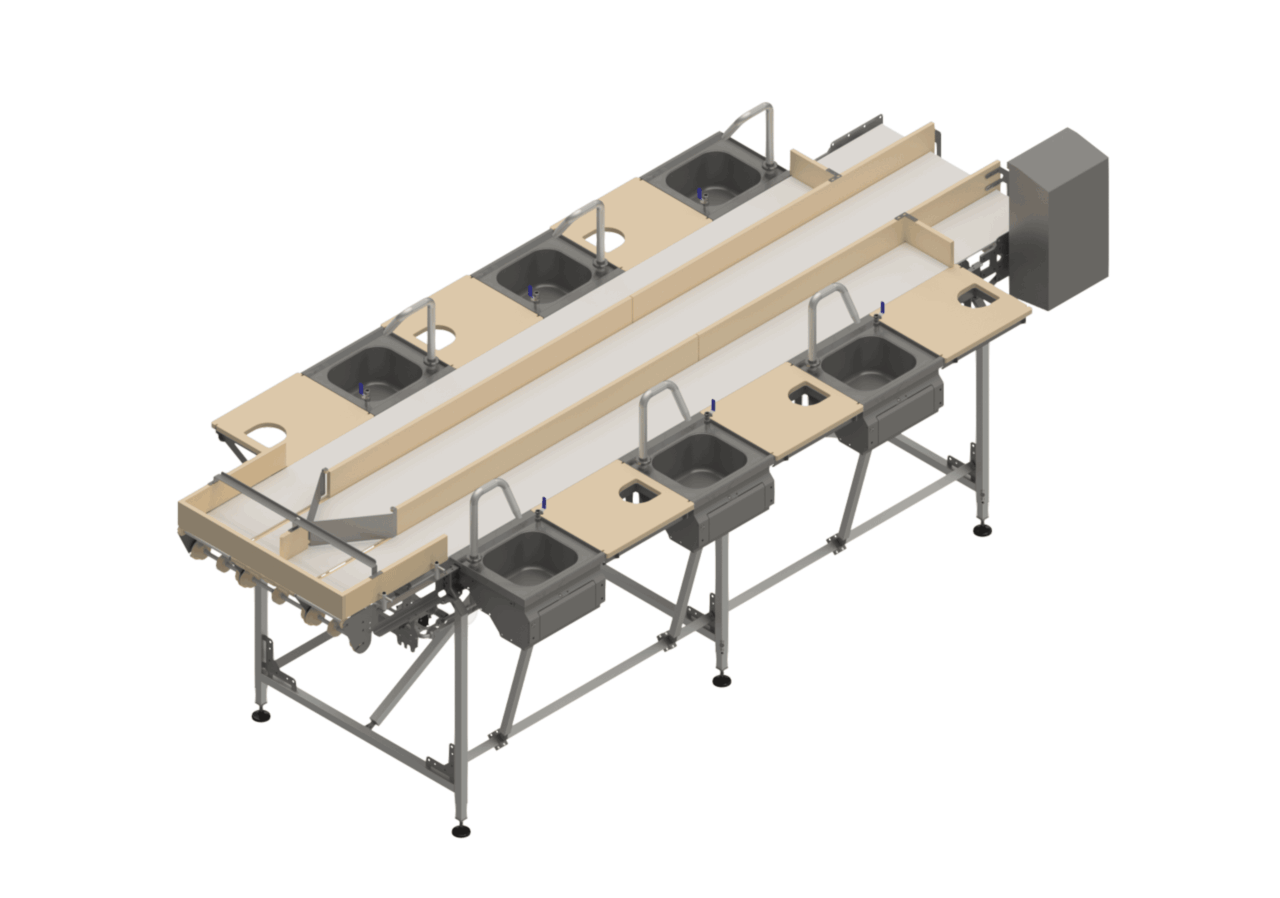

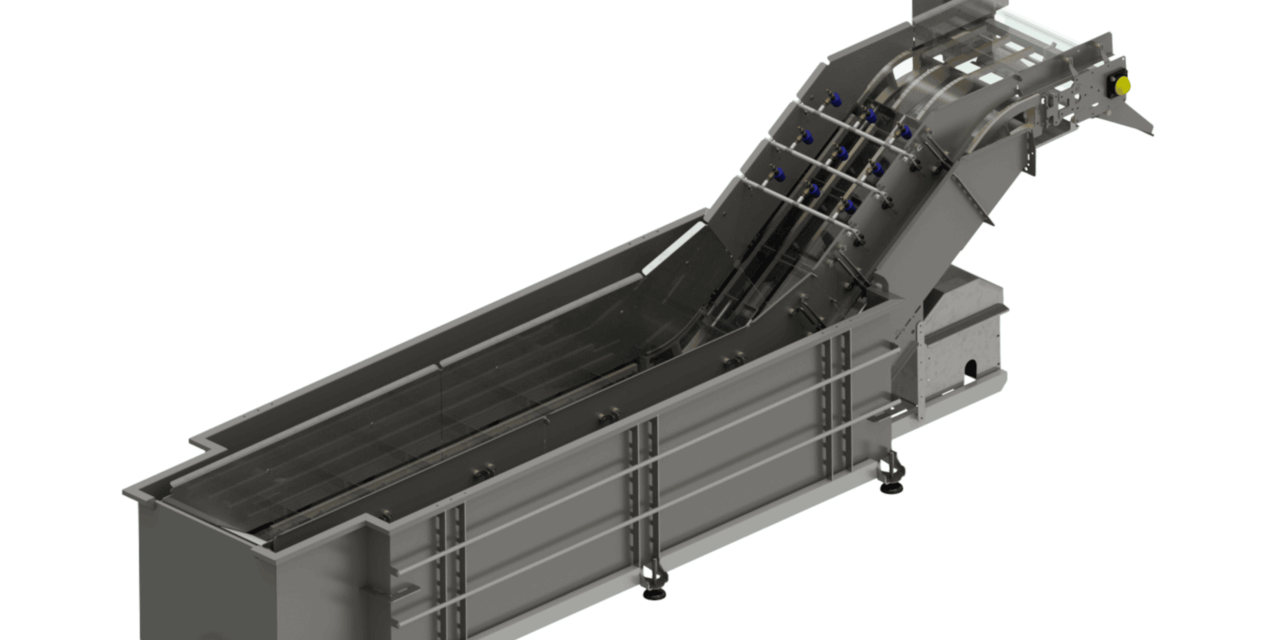

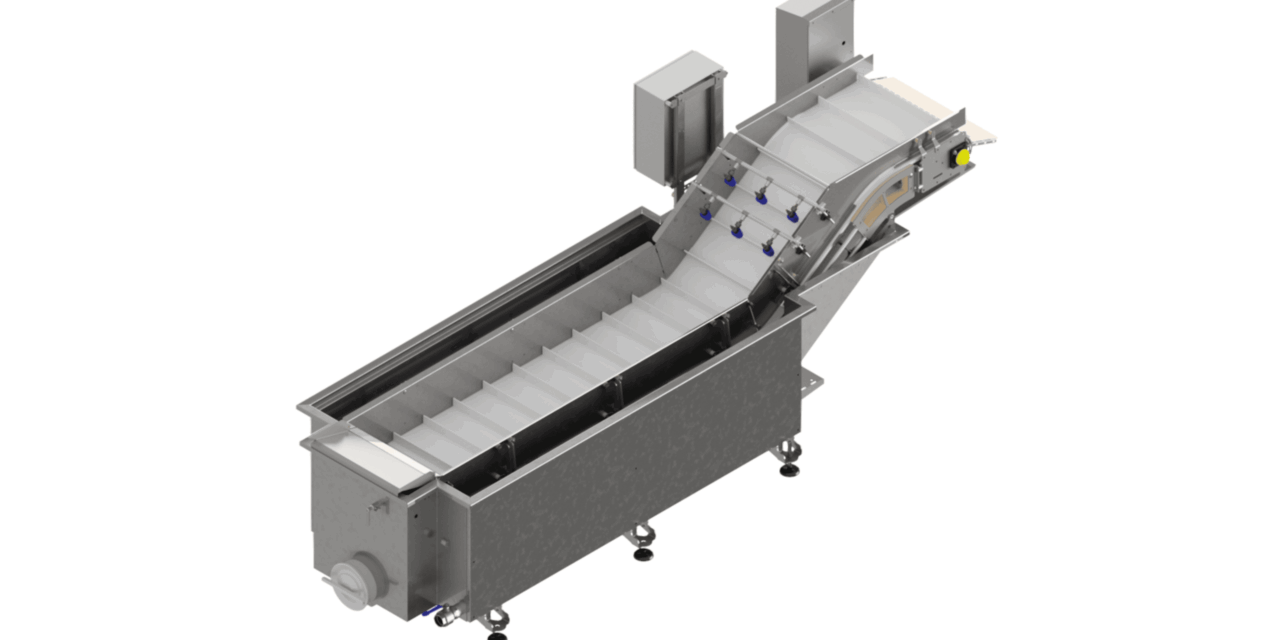

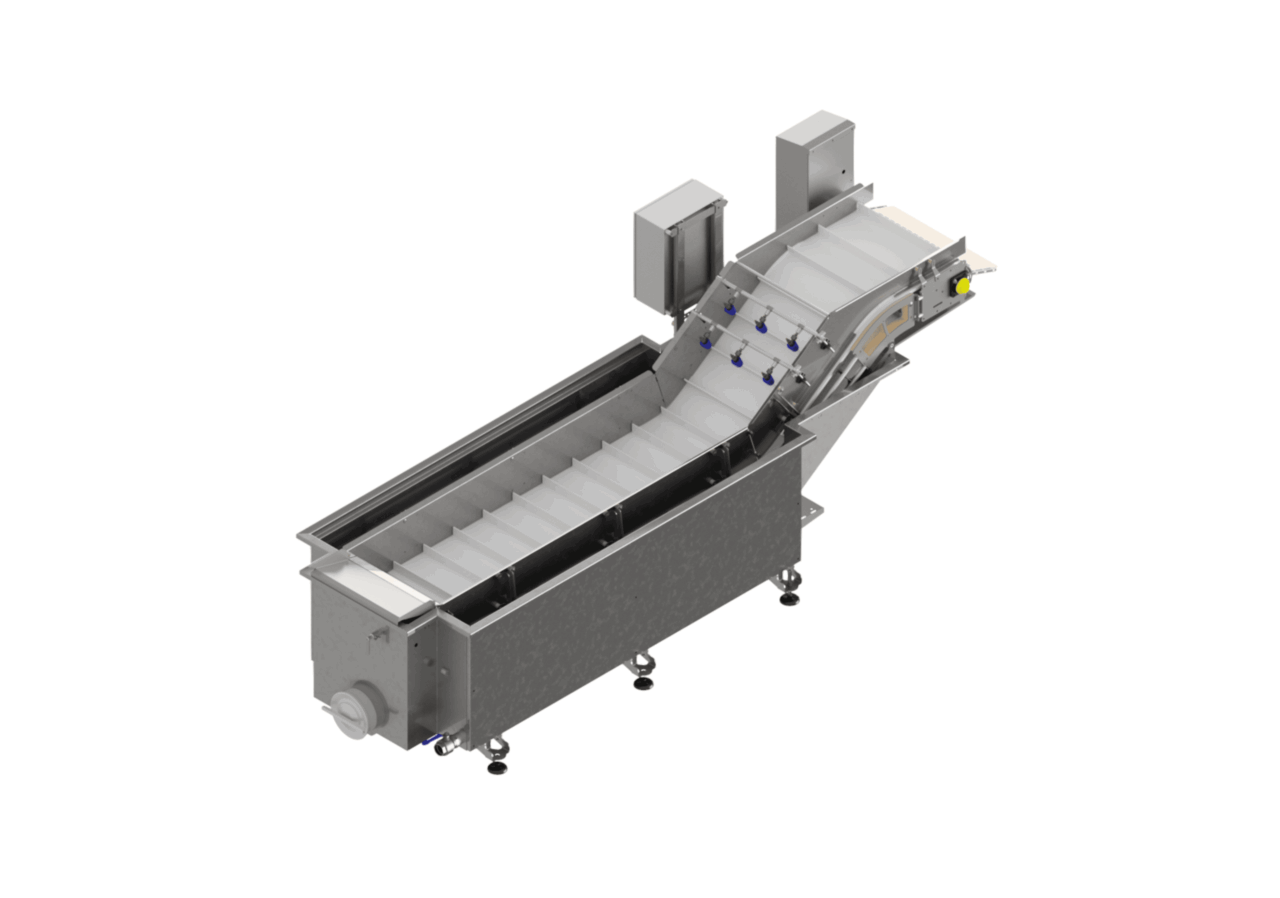

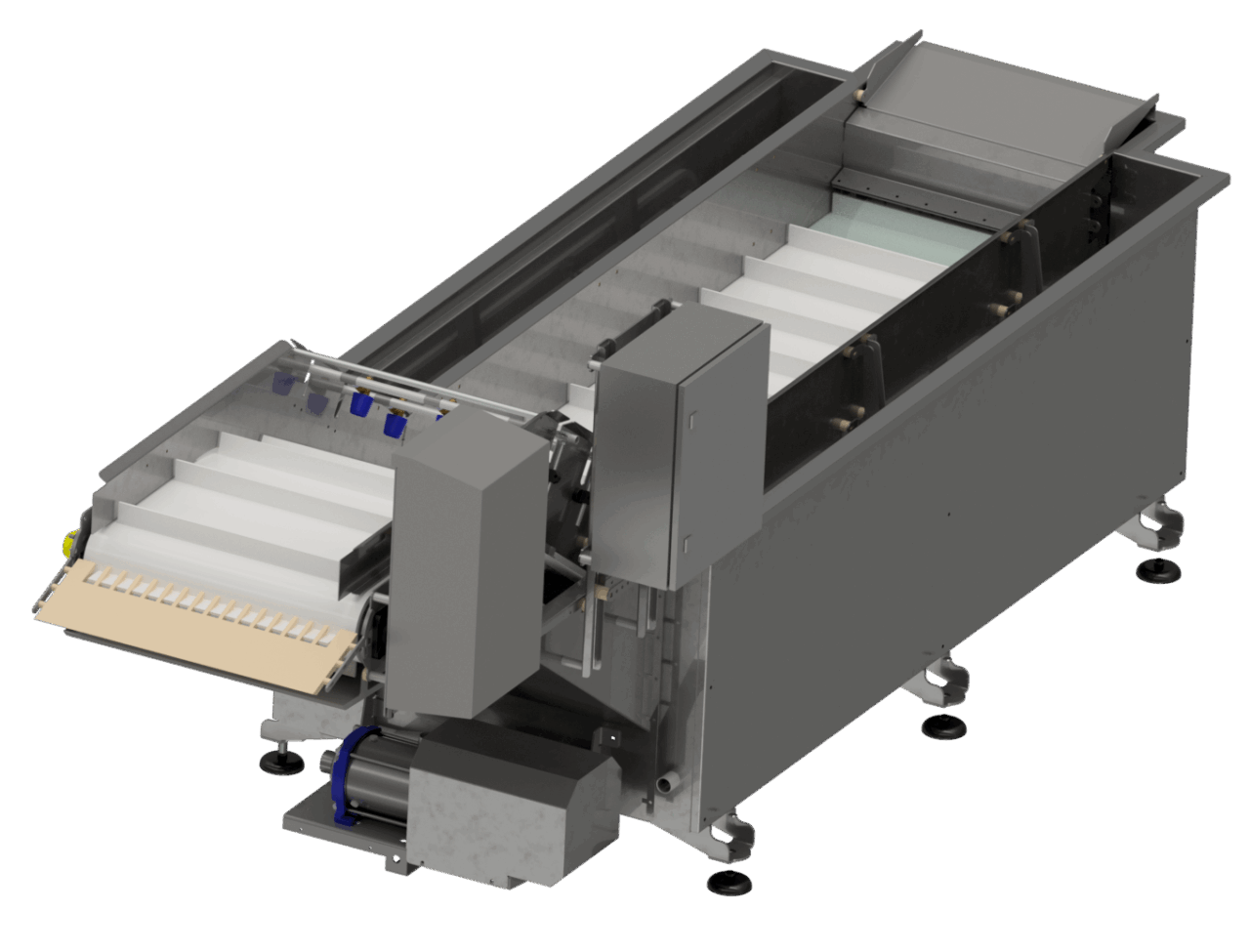

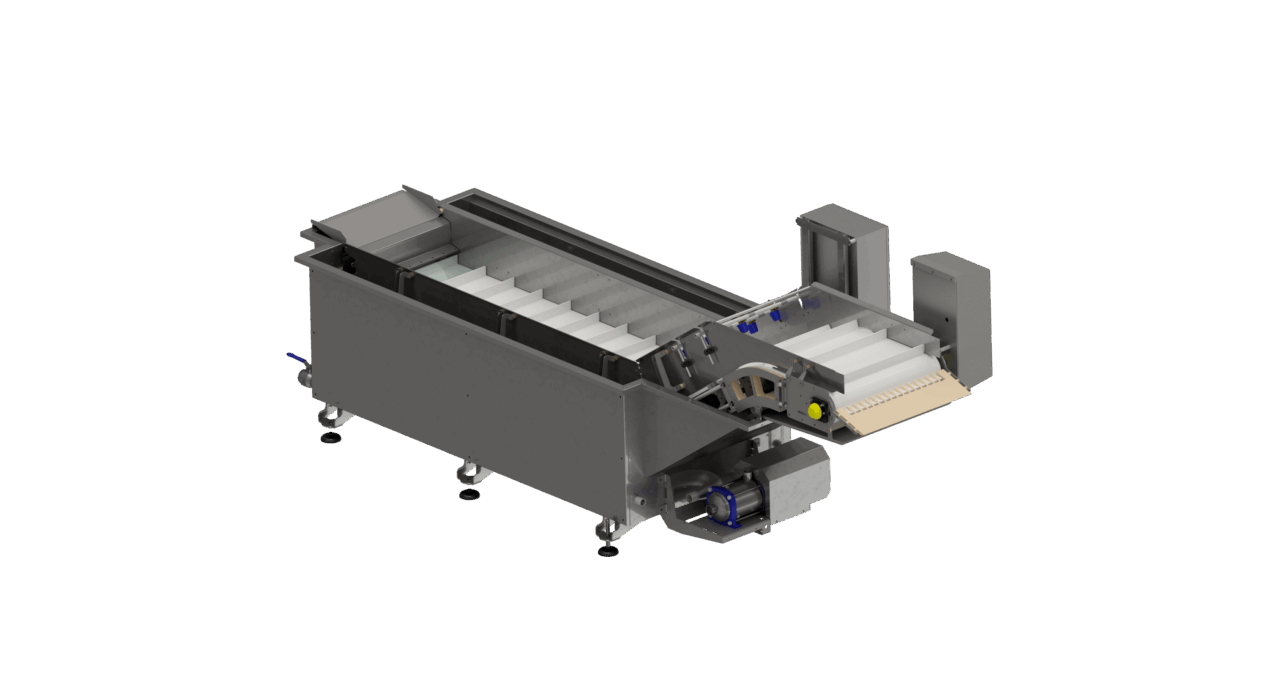

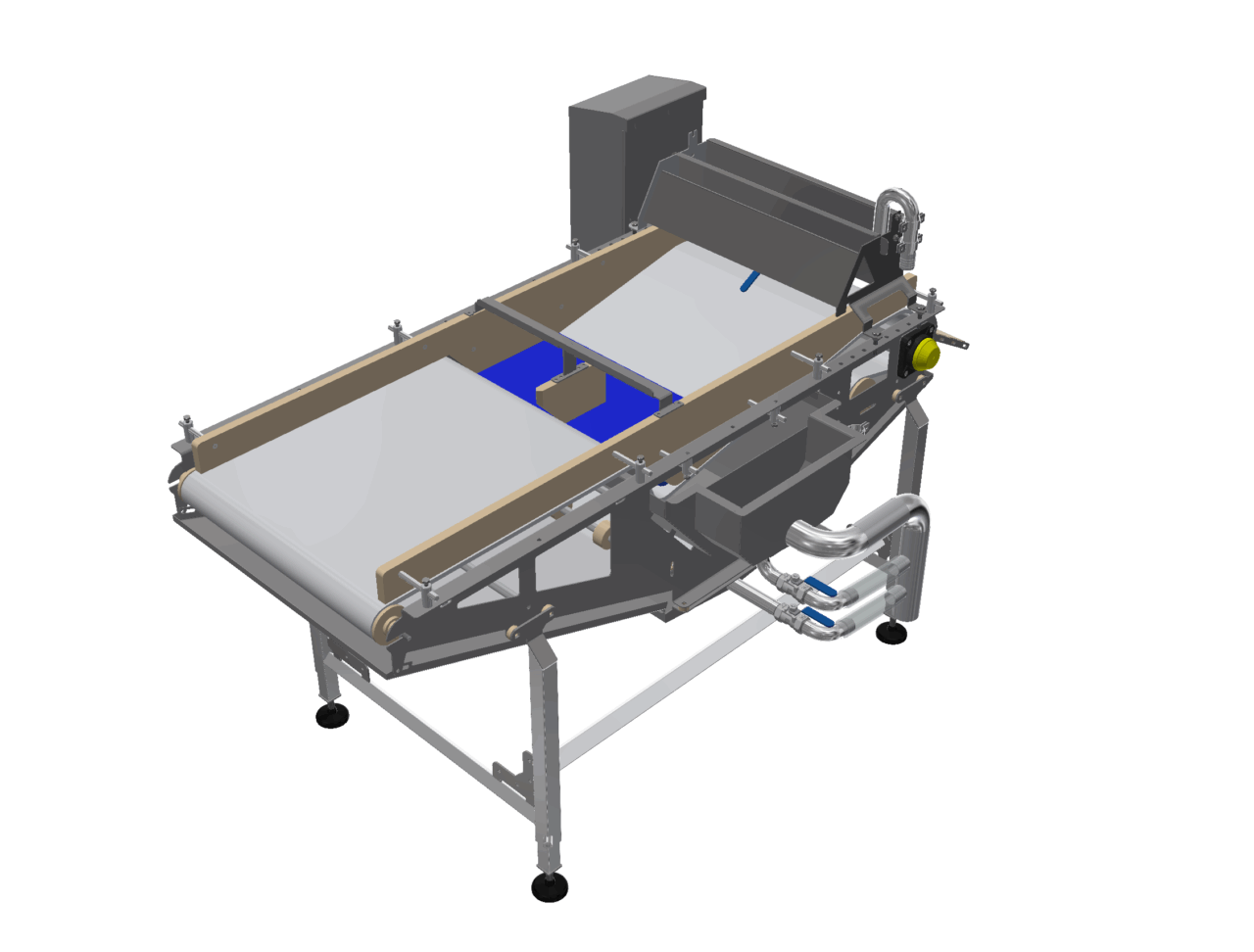

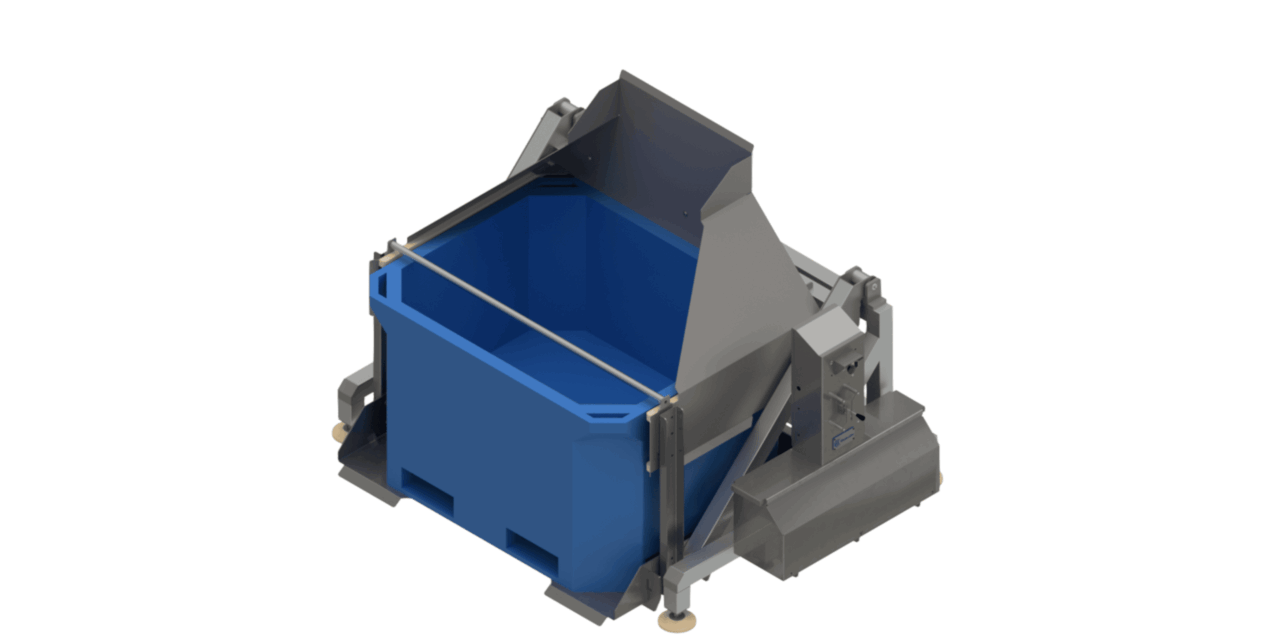

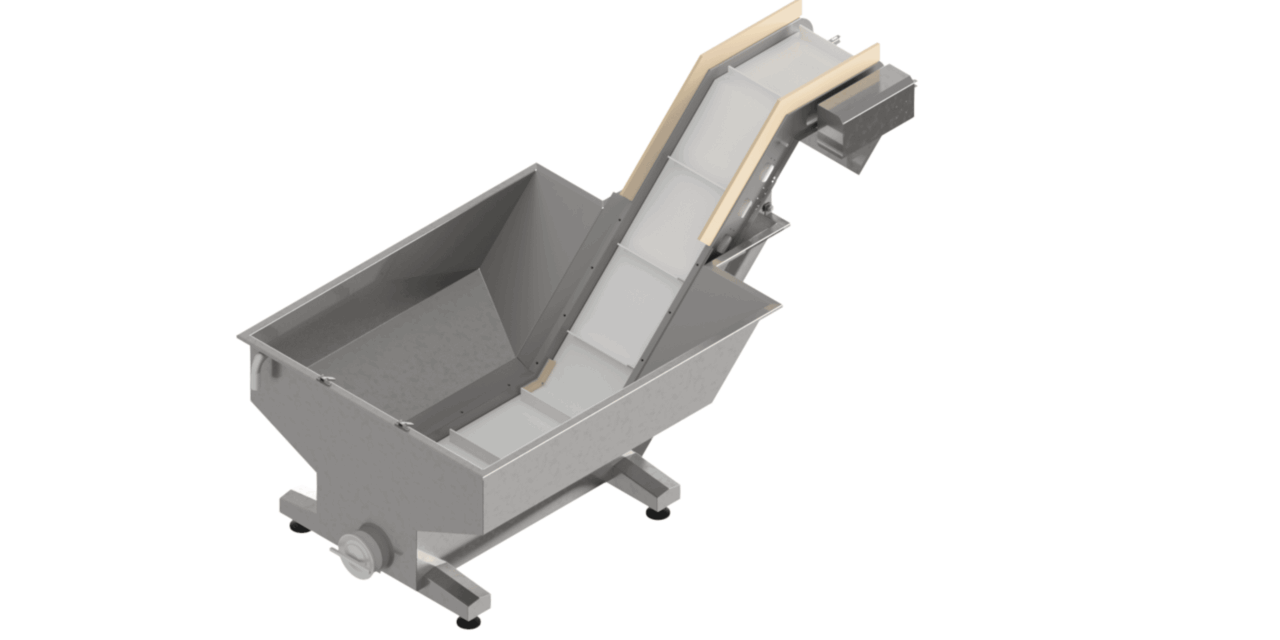

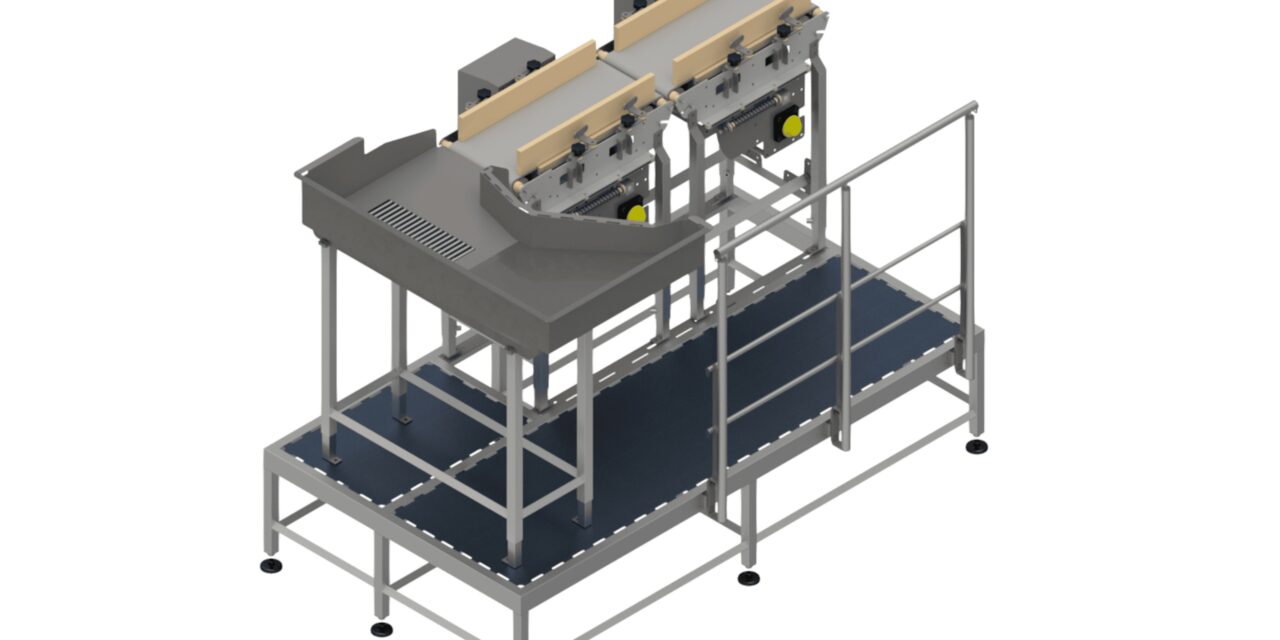

The Makelis defrosting system is suitable for defrostiong crushed fish/cephalopod blocks. It is contolled automatically from a control panel. The system defrosts the products as it immerses them in running water of a specific temperature. Each fish or cephalopod, when defrosted, falls to the bottom of the defroster and onto the conveyor belt. In this way, the product is transported out of the defroster and is ready for further processing.

Special Features

- Manufactured completely from stainless steel AISI 304

- Fitted with water pump for water circulation

- Air blowing system for blowing air inside the water

- Can defrost blocks at -25 C

- Outfeed convetor belt with flaps and speed requlator

- Water heating by electric element

- Temperature regulation with electronic instrument

- Opening for cleaning

- Joint for retracting the conveyor belt

- Hydraulic lifting of the belt

- 2” outlet valve

All the machines and the constructions of Makelis are customized to each individual need.