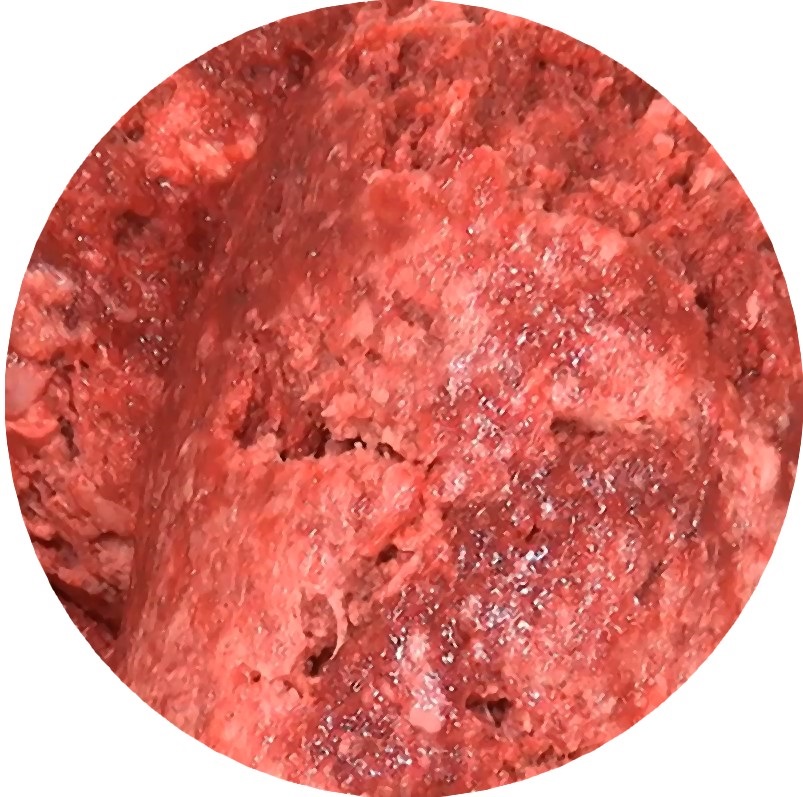

Lima’s DSP DSPM range of machines are specially designed to separate meat from hard bones, such as pork bones, to produce high quality structured meat with optimal performance and low calcium content. A specific filter with slots has been designed for this range of deboners to produce a high quality structured meat with technological characteristics close to ground meat. Specifically, the SM model range is equipped with a pre-breaking arm system which enables to feed the hopper with raw materials of big dimension without having to pre-cut them. Lima offers 14 different DSP models from 300kg/h (600lbs/h) to 15.000kg/h (33.000lbs/h)

Special features

Additional information