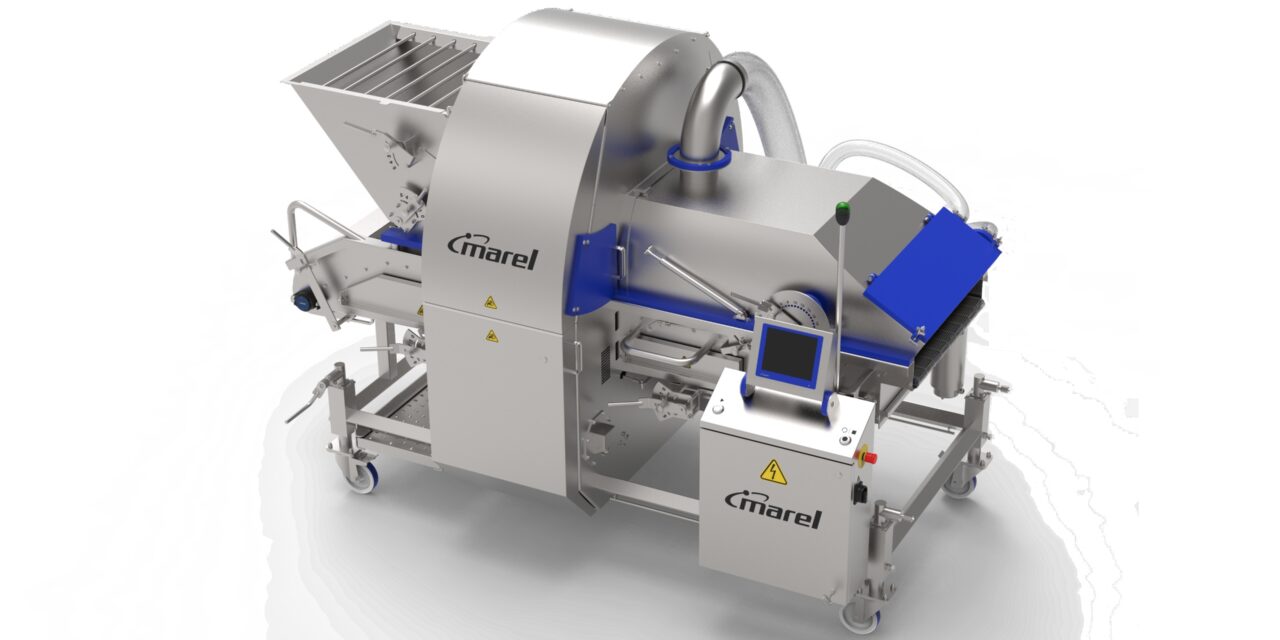

Coating machine – Marel RevoCrumb

The RevoCrumb produces perfectly coated products with optimum crumb distribution over all sides of the product.

Special Features

Additional information

The RevoCrumb produces perfectly coated products with optimum crumb distribution over all sides of the product.

Special Features

Additional information

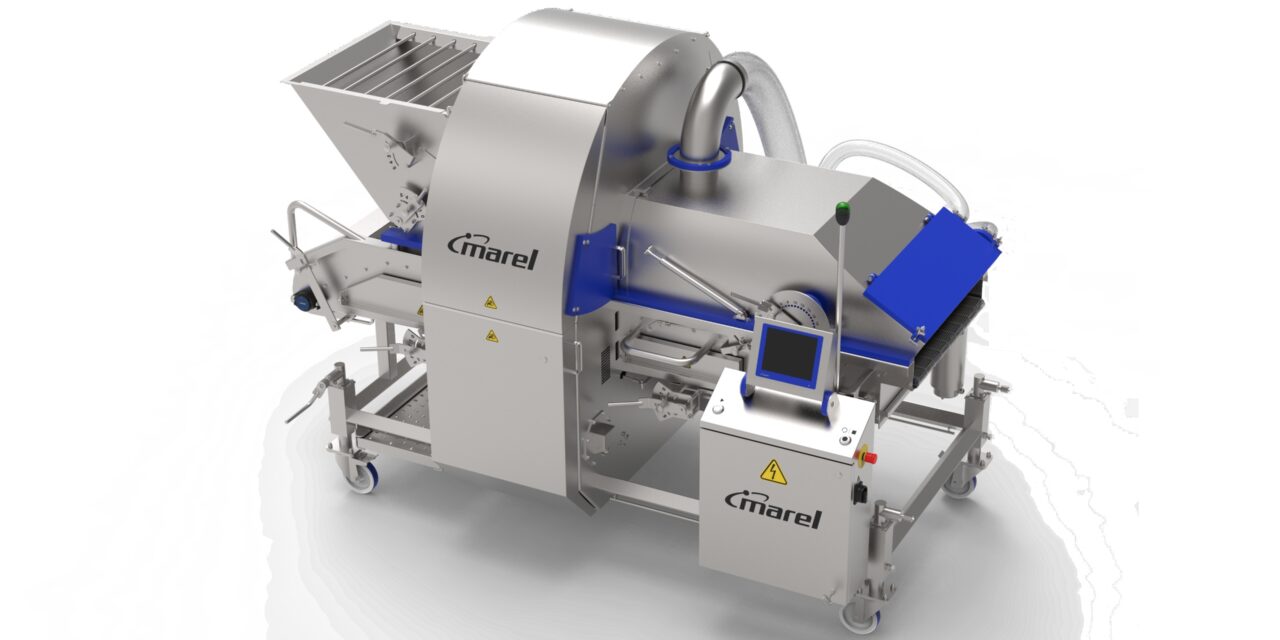

The RevoBreader is a multi-purpose, flexible machine that offers a flatbed mode and drum mode in one enclosure.

Special Features

Additional information

The Deslimer CT 1612.10 rinsing system efficiently rinses off slime, blood and bacteria from salmon, trout and other species similar in weight and texture.

CT 1612.10 CT 16.12.30 15 – 30 fish/min 40 – 60 fish/min 2,7 kW 3,3 kW 28 litres/min 48 litres/min ~500 kg ~650 kg

Special Features

Technical Features

Productivity

Power

Water consumption

Weight

Additional information

The CT 1636.20 fish fillet washer is suitable for preparing fish fillets before packing or cooling.

20-40 fish/min 32 l/min 7 kW 2300x1020x1600 mm 160 kg

Special Features

Technical Features

Productivity

Water consumption

Power

Dimensions (LxWxH)

Weight

Additional information

The salt and spice dispenser CT 1403.25 is suitable for fish fillets. The machine can handle salt, sugar/salt mixtures and various spices.

up to 40 fish/min 0,5 – 4 kg 50 mm ~50 kg 0,65 kW ~210 kg

Special Features

Technical Features

Productivity

Fillet range

Max. fillet height

Gross tank volume

Power

Weight

Additional information

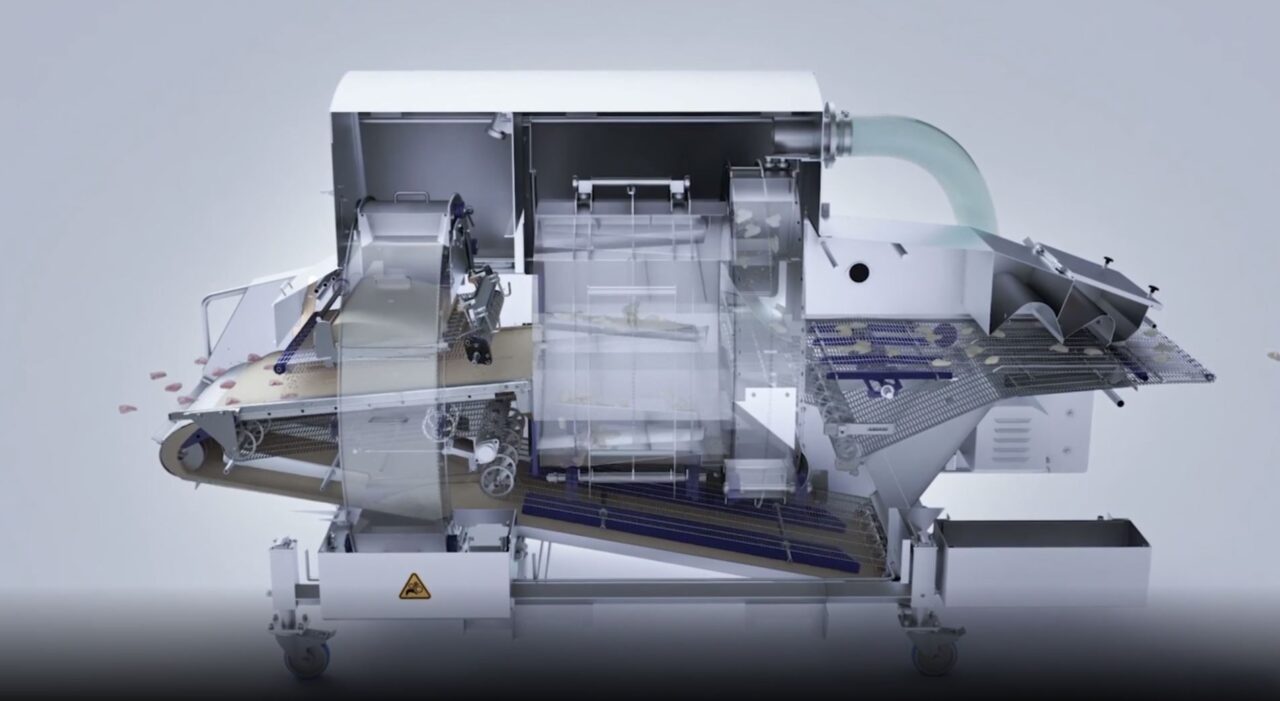

The Platino uses a unique technology to flatten products. The Platino method puts less pressure on the product by massaging it over a shorter period of time than other flattening equipment. This results in a high-quality bite, texture and taste. The massaging effect leaves the product more pliable which results in increased and faster brine or marinade absorption during tumbling. Suitable for boneless, non-frozen poultry, the machines deliver portions that maintain both their quality and shape after flattening.

Platino 400 Platino 800 2250x1045x1450 mm 2250x1450x1450 mm 400 mm 800 mm 1000 +/- 50 mm 1000 +/- 50 mm

Special Features

Technical Specifications

Versions

Dimensions (LxWxH)

Belt width

Belt height from the floor

Additional information