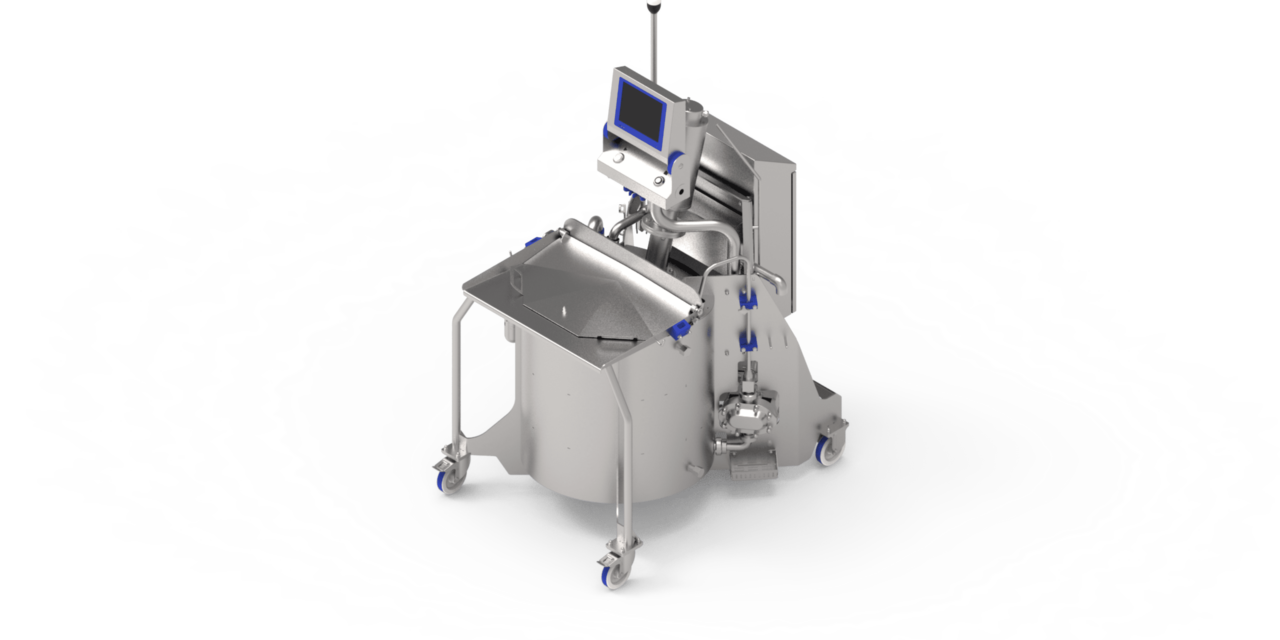

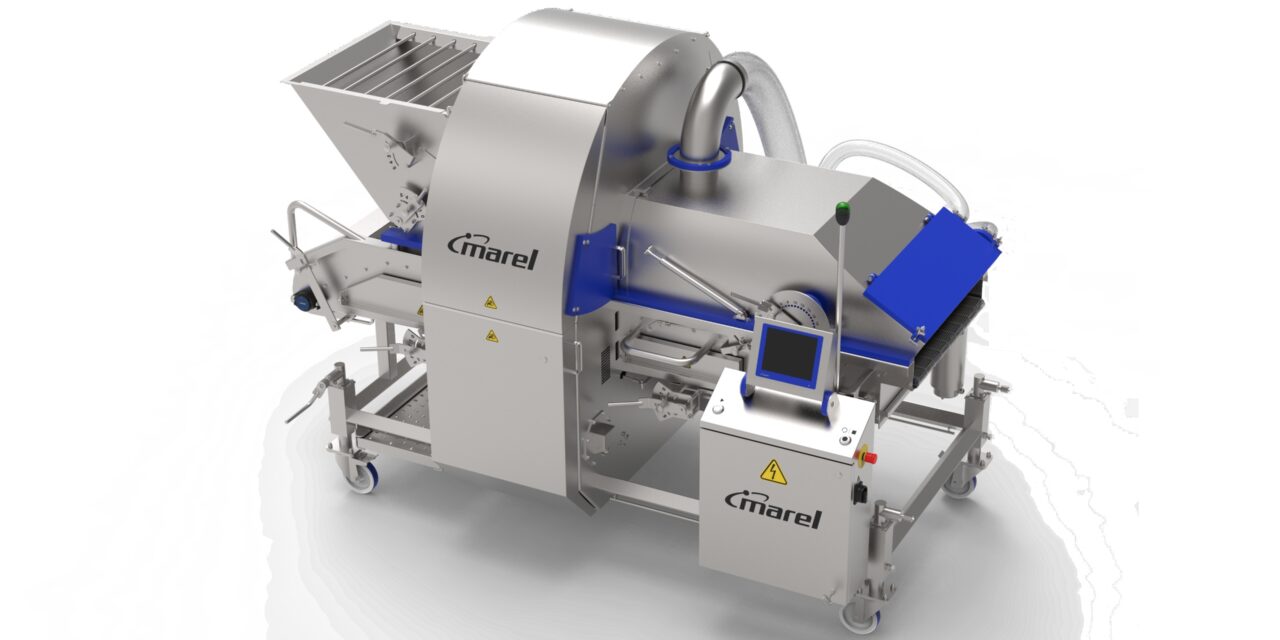

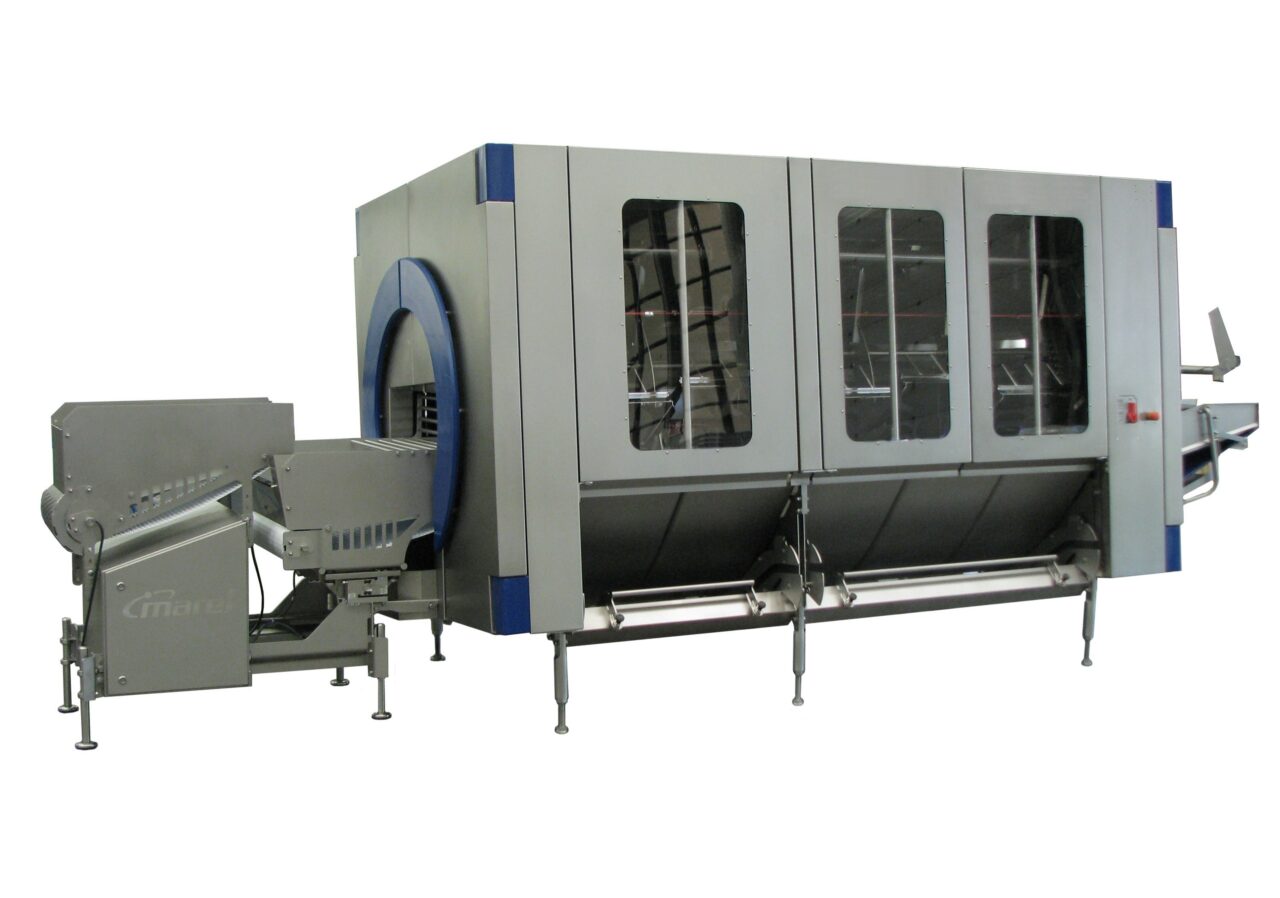

Marel ValueDrum

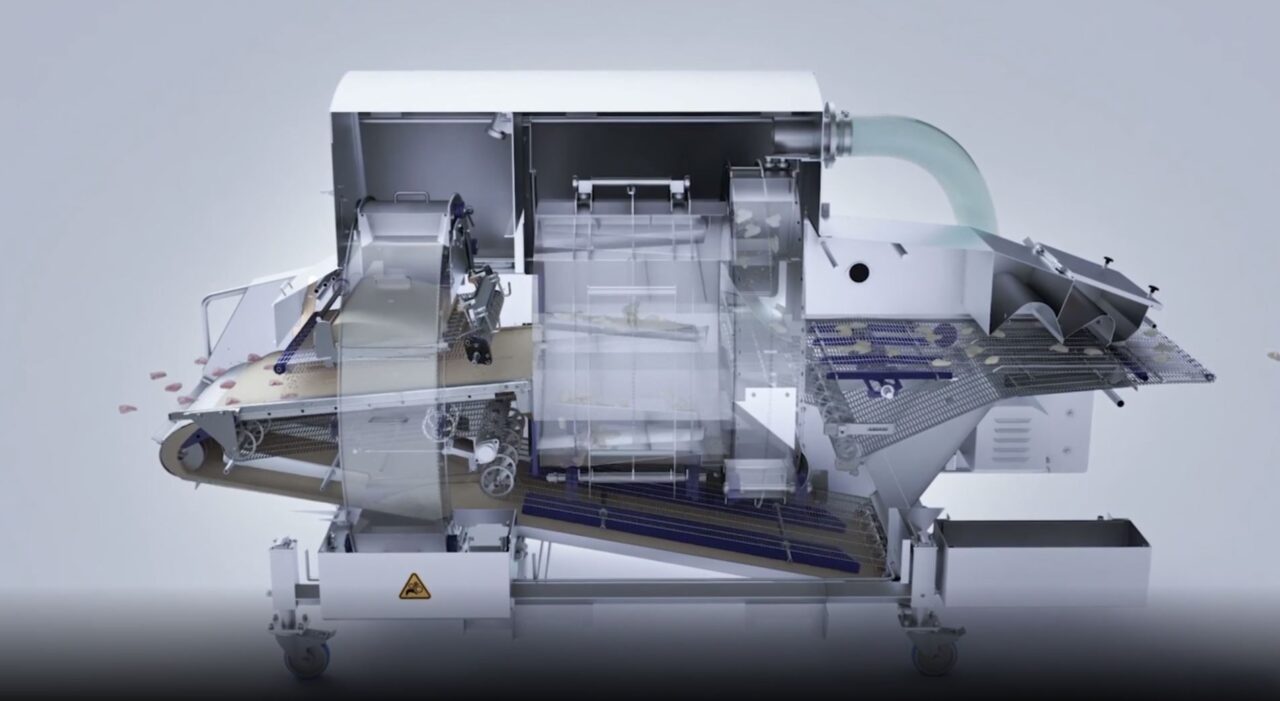

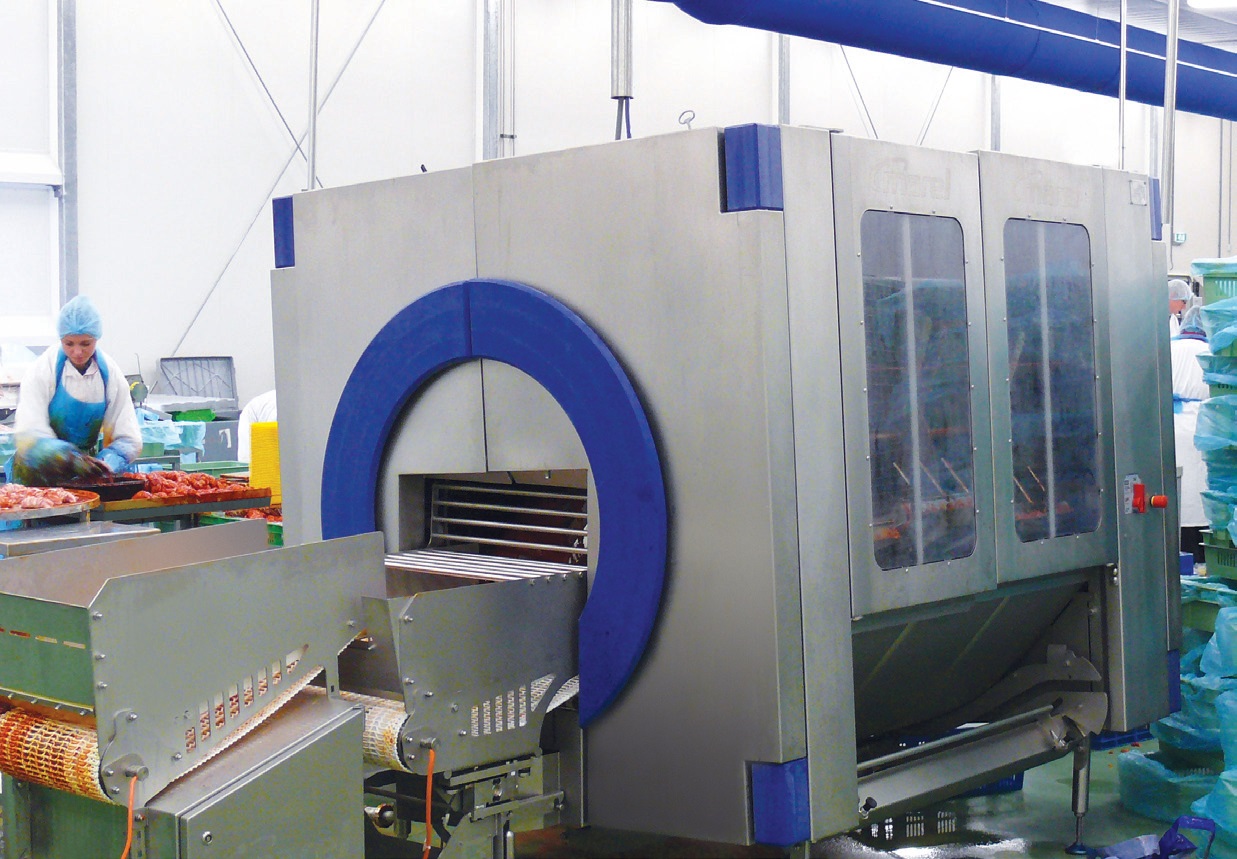

Unlike conventional tumblers which are loaded batch by batch and mainly by hand, ValueDrum features integrated inline production of coated or marinated fresh products. ValueDrum’s in-line principle of processing smaller portions with the possibility of applying specific massage components and the controlled method of adding different ingredients in a sequence, leads to a much more constant product quality.

Special Features

Highly accurate positioning