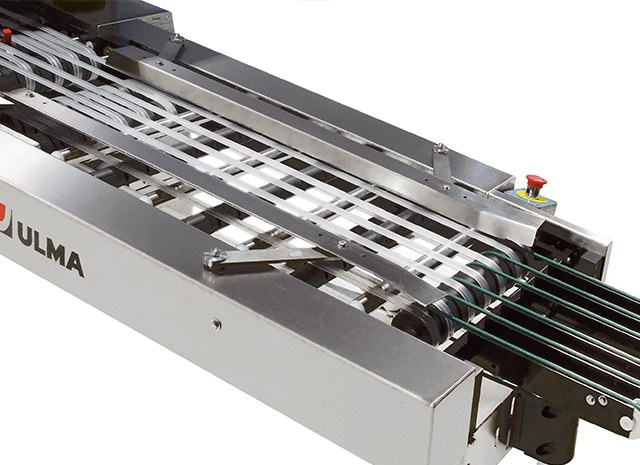

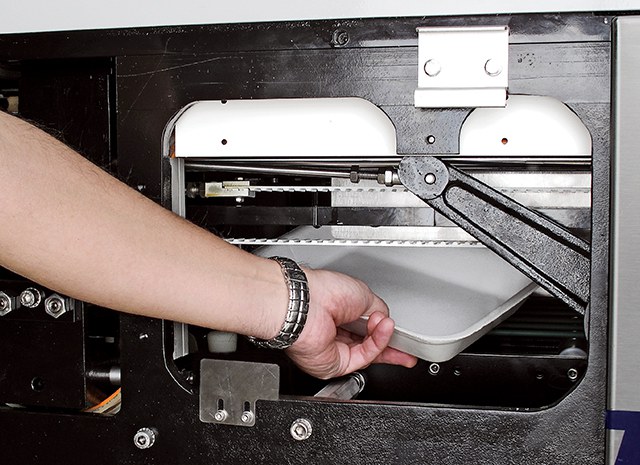

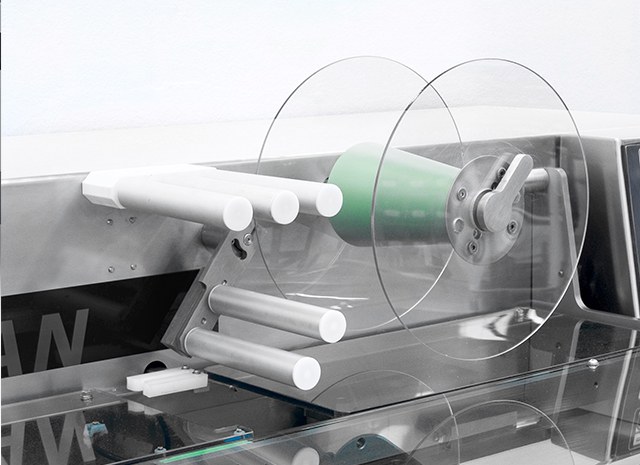

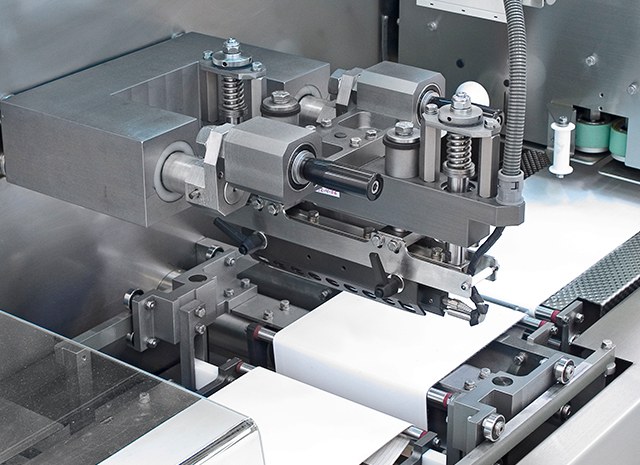

Horizontal Flow Wrapper (HFFS) that makes a totally hermetic and leak proof three sealing pillow pack for meat and poultry packing in trays. Specifically designed to work with stretch shrink films.

Special features

- Flexible electronic machine to wrap products up to 280 mm (11″) wide and 180 mm. (7″) high

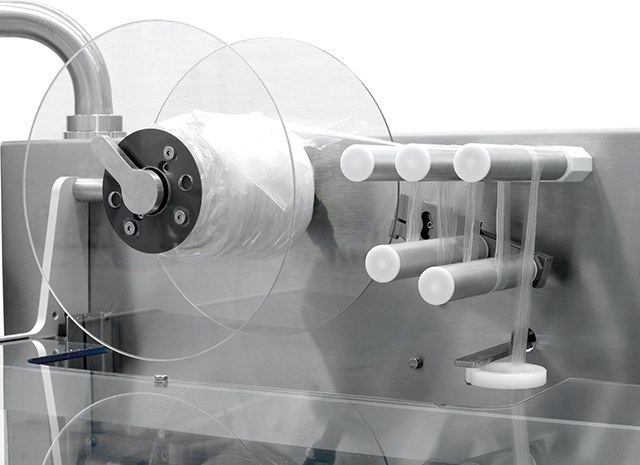

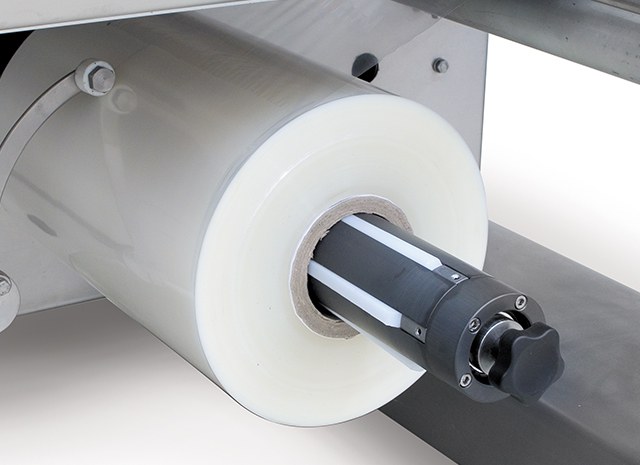

- Printed and non printed films

- UPC control (ULMA industrial PC) with 15″ touch screenpanel.

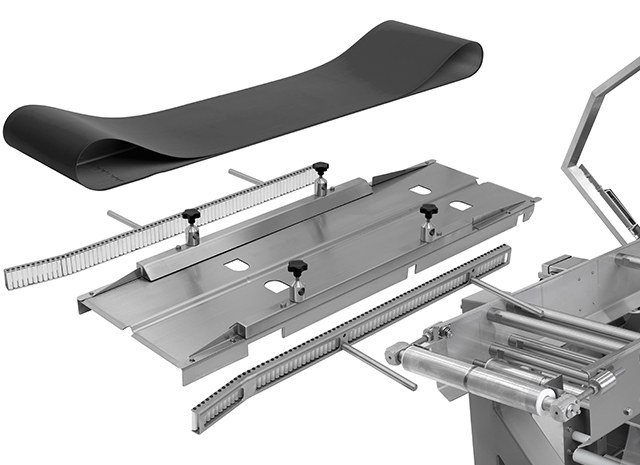

- Minimum product changeover time

- Fresh food oriented design for easy cleaning and optimum machine sanitation

- Protection IP65 (or higher)

- Wash down construction automatic feeding system

- The FS 400 system includes a wide range of hot air and hot water shrink tunnels that provide to the case-ready packs the required optimum package appearance

Additional information