Batter Mixer – Marel Active Mixer

This semi-automatic mixer takes powder and water and turns it into a liquid, homogeneous mixture, which can be tempura or a lower viscosity batter.

Special Features

Additional information

This semi-automatic mixer takes powder and water and turns it into a liquid, homogeneous mixture, which can be tempura or a lower viscosity batter.

Special Features

Additional information

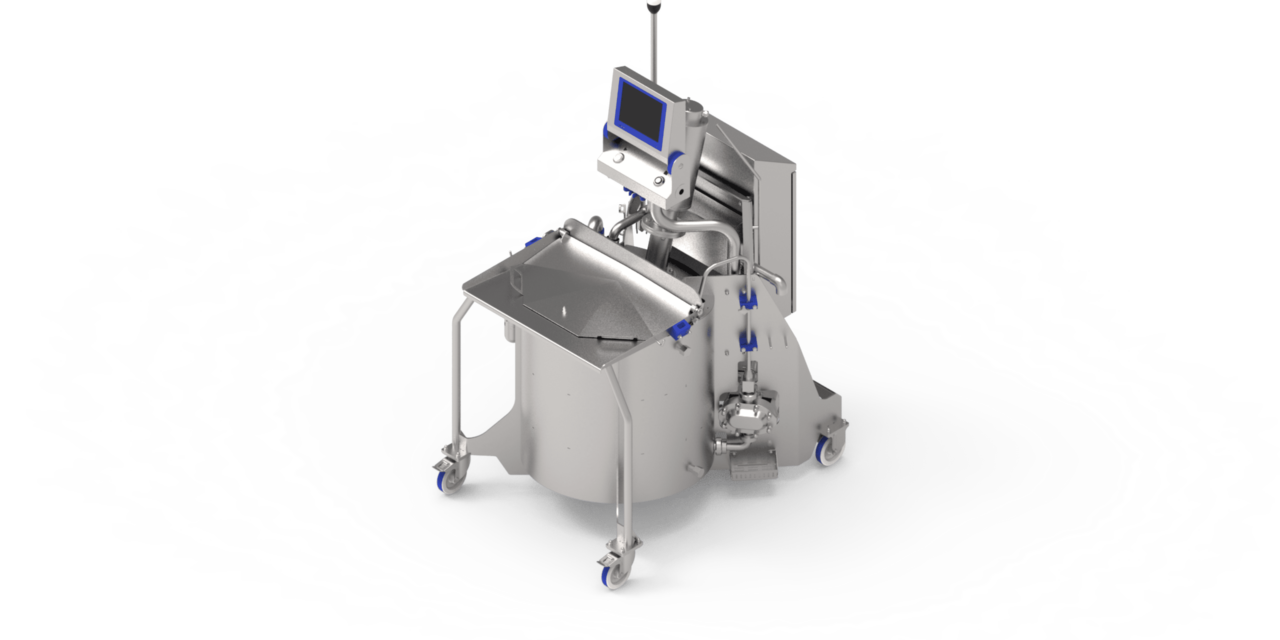

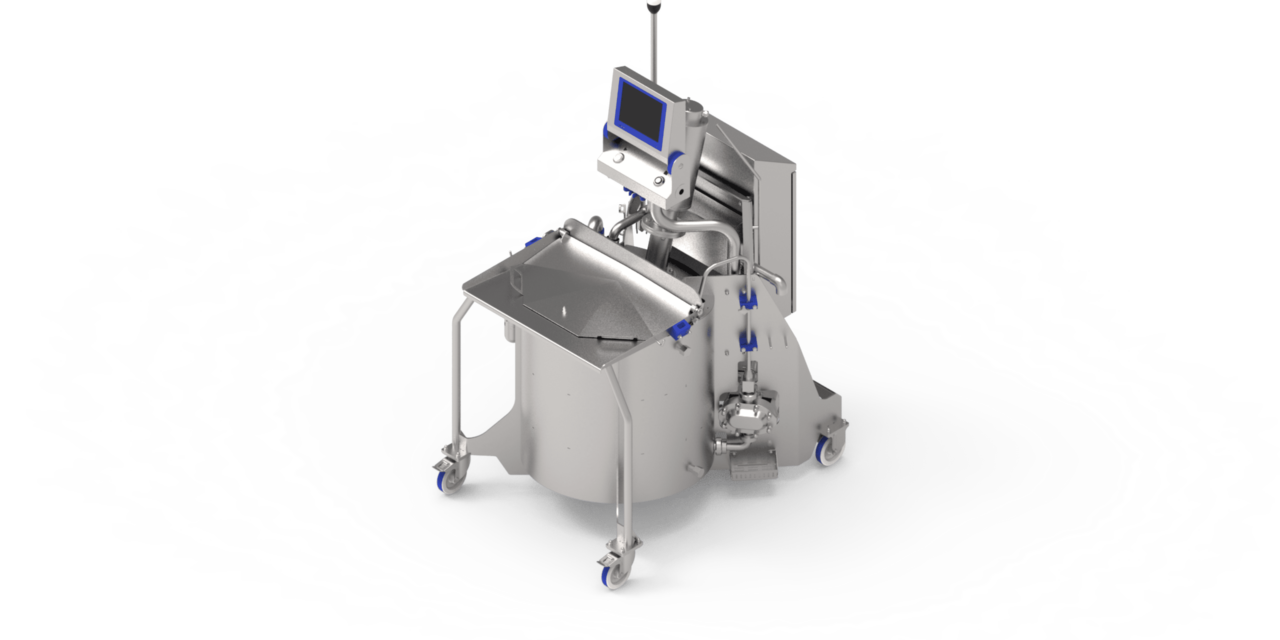

Vacuum machine 600 liters suitable for tumbling, mixing, marinating.

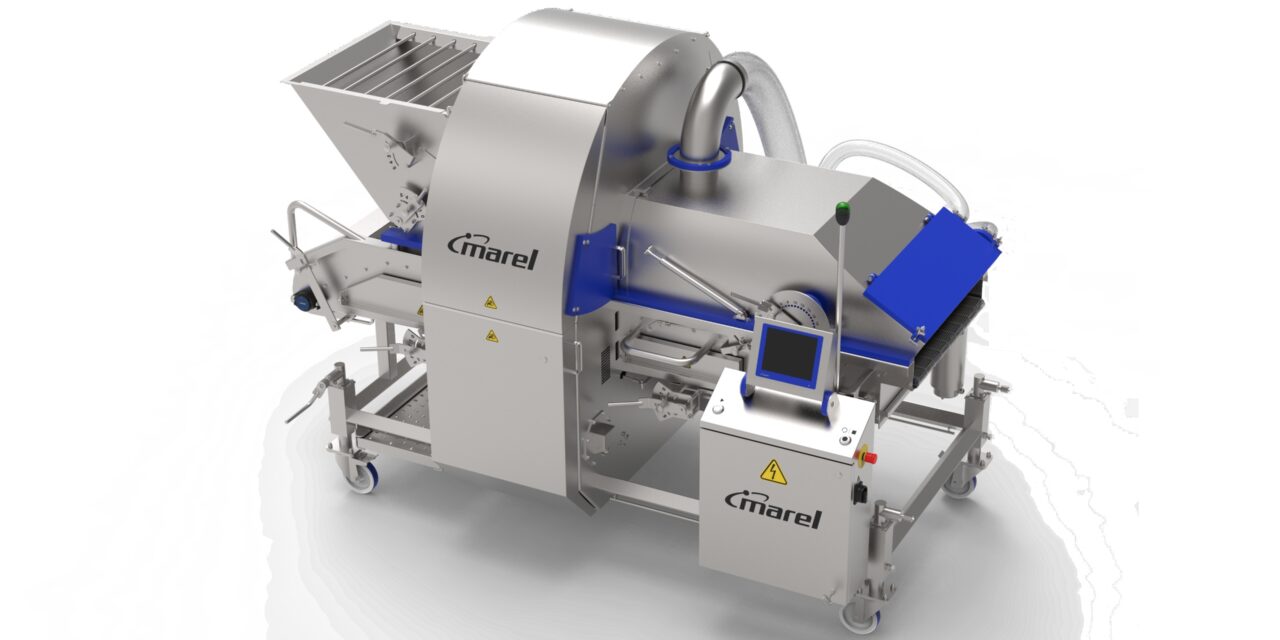

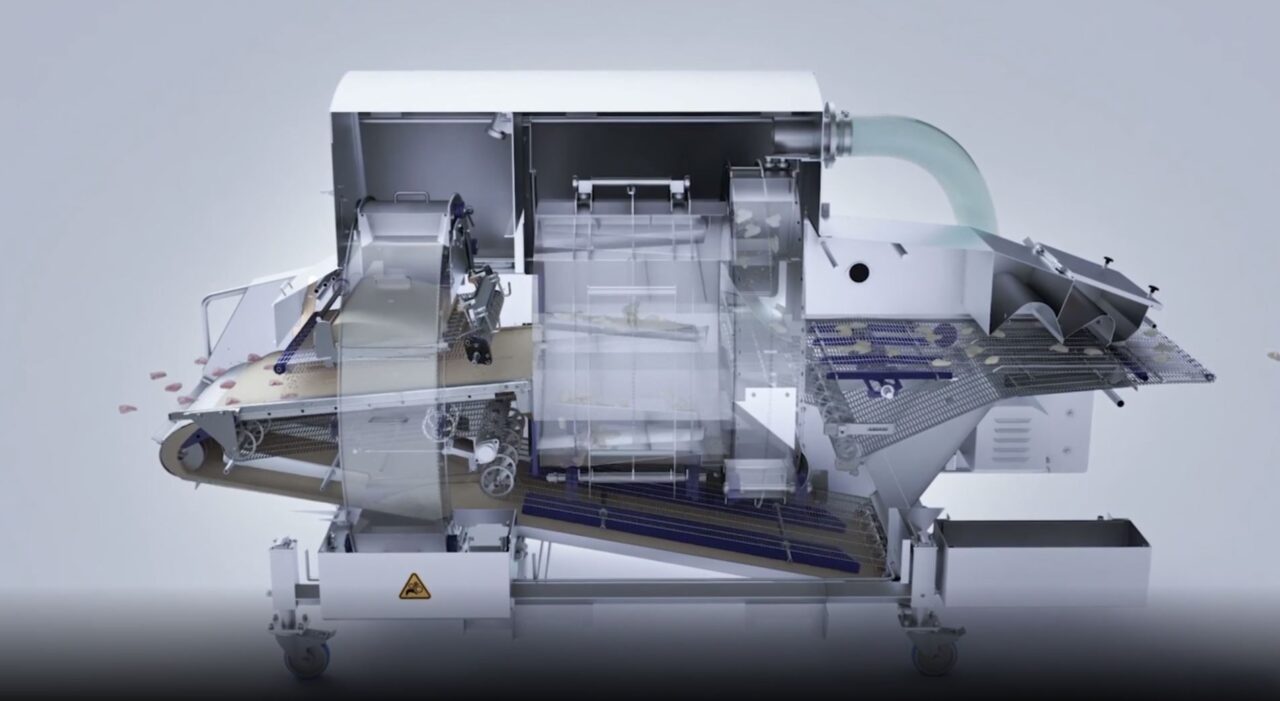

The active batter applicator of Marel creates an even and consistent wet coating. When products enter the machine, they transfer onto a bed of batter rather than directly onto a belt. This unique way of transporting the products through the machine ensures the underside is completely coated and belt marks virtually eliminated.

Special Features

Additional information

Vacuum machine 900 liters suitable for tumbling, mixing, marinating.

Vacuum machine 1500 liters suitable for tumbling, mixing, marinating.

Vacuum machine 1500 liters suitable for tumbling, mixing, marinating.

| Dimensions (LxWxH) |

2180x1630x1960 mm |

| Payload |

950 kg |

| Tank speed |

2-20 rpm |

| Weight |

1170 kg |

| Power |

5,4 kW |

The Active Flour Applicator applies a fine coating of flour to products with a smooth surface creates a good adhesive layer that better absorbs batter and other coatings.

Special Features

Additional information

The RevoCrumb produces perfectly coated products with optimum crumb distribution over all sides of the product.

Special Features

Additional information

The RevoBreader is a multi-purpose, flexible machine that offers a flatbed mode and drum mode in one enclosure.

Special Features

Additional information

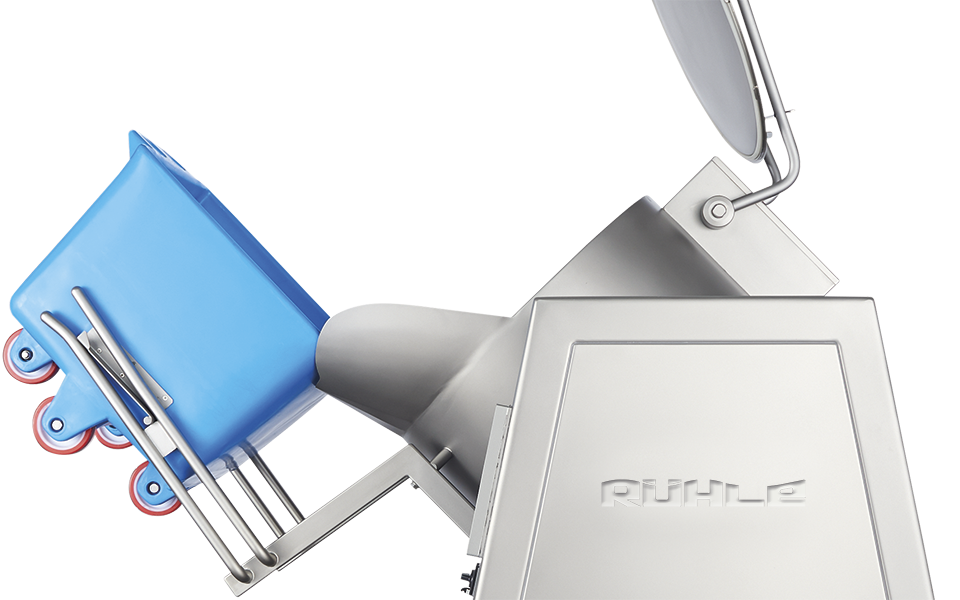

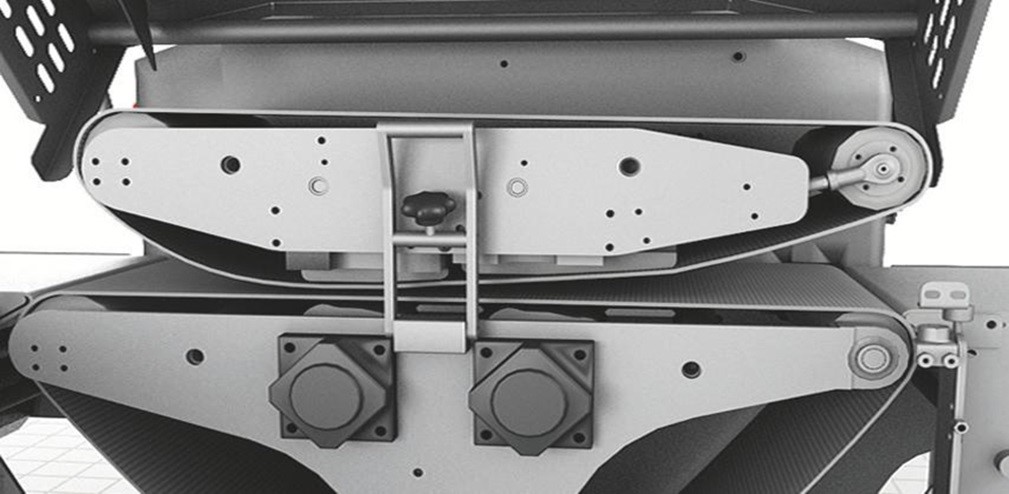

The Platino uses a unique technology to flatten products. The Platino method puts less pressure on the product by massaging it over a shorter period of time than other flattening equipment. This results in a high-quality bite, texture and taste. The massaging effect leaves the product more pliable which results in increased and faster brine or marinade absorption during tumbling. Suitable for boneless, non-frozen poultry, the machines deliver portions that maintain both their quality and shape after flattening.

Platino 400 Platino 800 2250x1045x1450 mm 2250x1450x1450 mm 400 mm 800 mm 1000 +/- 50 mm 1000 +/- 50 mm

Special Features

Technical Specifications

Versions

Dimensions (LxWxH)

Belt width

Belt height from the floor

Additional information