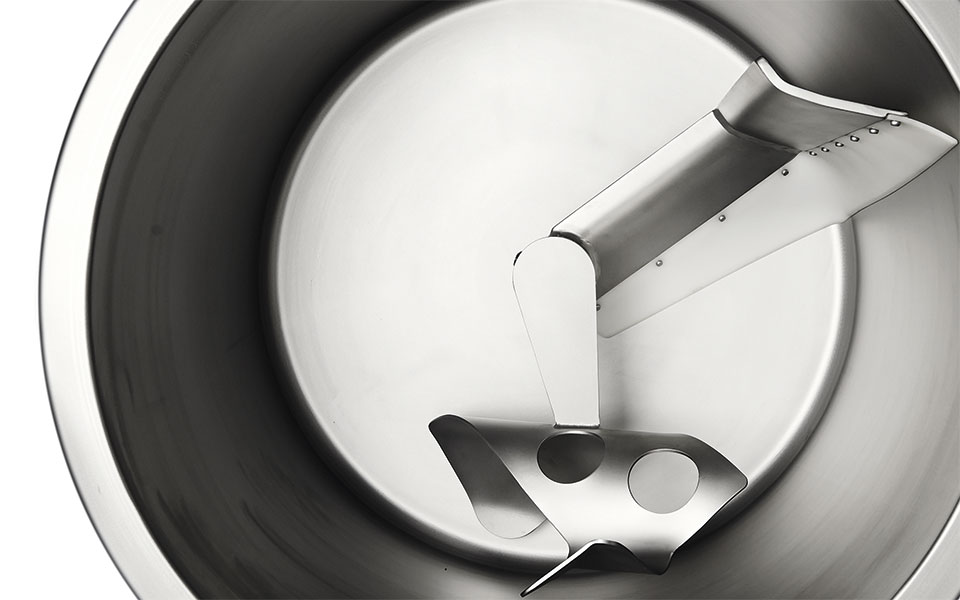

Marel’s Mixer-Grinders are specifically designed for industrial use and they ensure a quick, gentle end homogeneous mixing process.

Special Features

Additional information

Marel’s Mixer-Grinders are specifically designed for industrial use and they ensure a quick, gentle end homogeneous mixing process.

Special Features

Additional information

Oscar 20 is an automatic and hydraulic stuffer. It is portable and flexible to be placed anywhere in production. In addition to the production of classic cold cuts and sausages, the Oscar 20 is often used for delicatessens production.

Special Features

Technical Specifications

Cylinder Capacity

20 l

Gross Weight

150 kg

Power

0,75 kW

Power Supply

400V, 50Hz, 3phase

Dimensions (HxLxW)

105x50x60 cm

Additional information

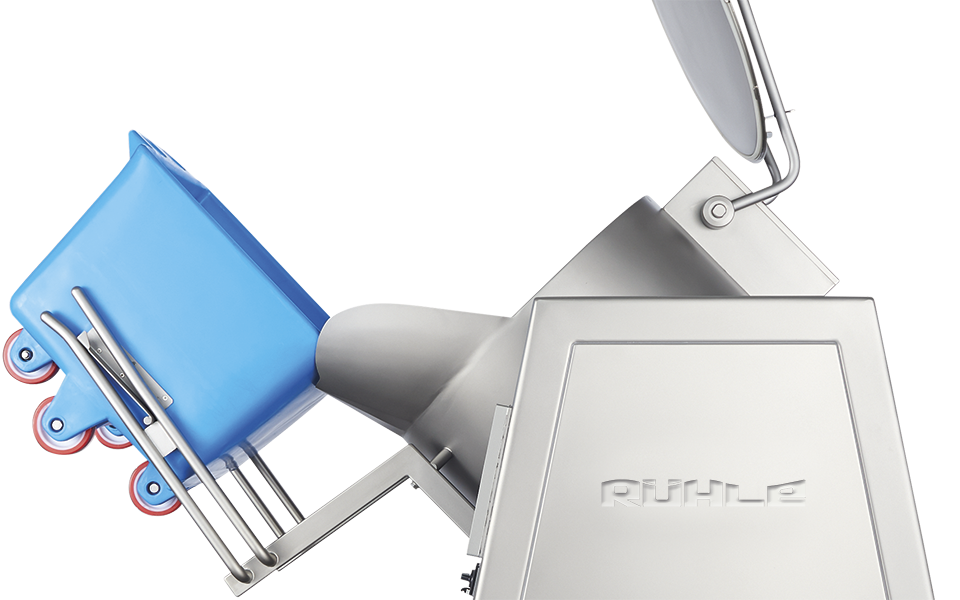

MF 30-4 is 30 liters piston stuffer for straight filling. It was designed and built CE-conform according the strict safety and hygiene requirements of the CE-regulations.

Special Features

Technical Specifications

Cylinder Capacity

30 l

Gross Weight

300 kg

Ισχύς

1,1 kW

Power Supply

400V, 50Hz, 3phase

Additional information

The Kompakta 2 works like a straight filling, portioning and linking machine. The wide and extremely short outlet cares for a good finish for filling coarse meat and especially sausage meat.

Special features

Technical Specifications

Cylinder capacity

30l

Gross Weight

300 kg

Power

3,3 kW

Power Supply

400V, 50Hz, 3phase

Processing quantity

Up to 250 portions/min

Additional information

F-LINE F40, F52 and F60 are the entry-level models in the vacuum. Suitable for connection with all additional equipment for the production of burgers, sausages and other meat products. The vacuum pump is sucking off resting air bubbles (gaps) from the product. You get a perfect sausage aspect – the subsequent natural reddening is improved.

F-40 40 l 1900 kg/h 30 bar 82 g 8 0,1-99.999 g

F-52 25/90 l 2500 kg/h 40 bar 82 g 8 0,1-99.999 g

F-60 25/90 l 2900 kg/h 40 bar 82 g 8 0,1-99.999 g

Special features

Technical Specifications

F-LINE

F-40

F-52

F-60

Capacity

40 l

25/90 l

25/90 l

Max.performance

1900 kg/h

2500 kg/h

2900 kg/h

Filling Pressure up to

30 bar

40 bar

40 bar

Chamber capacity

82 g

82 g

82 g

Filling chambers

8

8

8

Portioning range

0,1-99.999g

0,1-99.999g

0,1-99.999g

Power Supply

3Ph./PE, 400V, 50/60Hz

3Ph./PE, 400V, 50/60Hz

3Ph./PE, 400V, 50/60Hz

Sucking power of vacuum pump

16 m/h

16 m/h

16 m/h

Weight

380 Kg

430 Kg

430 Kg

Portioning speed max.

300 port/min.

450 port/min.

530 port/min.

Technical Features

F-LINE

Capacity

Max.performance

Filling Pressure up to

Capacity of the chambers

Filling chambers

Portioning range

F-LINE

Capacity

Max.performance

Filling Pressure up to

Capacity of the chambers

Filling chambers

Portioning range

F-LINE

Capacity

Max.performance

Filling Pressure up to

Capacity of the chambers

Filling chambers

Portioning range

Additional information

Vacuum machine 220 liters suitable for tumbling, mixing, marinating.

Vacuum machine 150 liters suitable for tumbling, mixing, marinating.

Vacuum machine 220 liters suitable for tumbling, mixing, marinating.

Vacuum machine 300 liters suitable for tumbling, mixing, marinating.

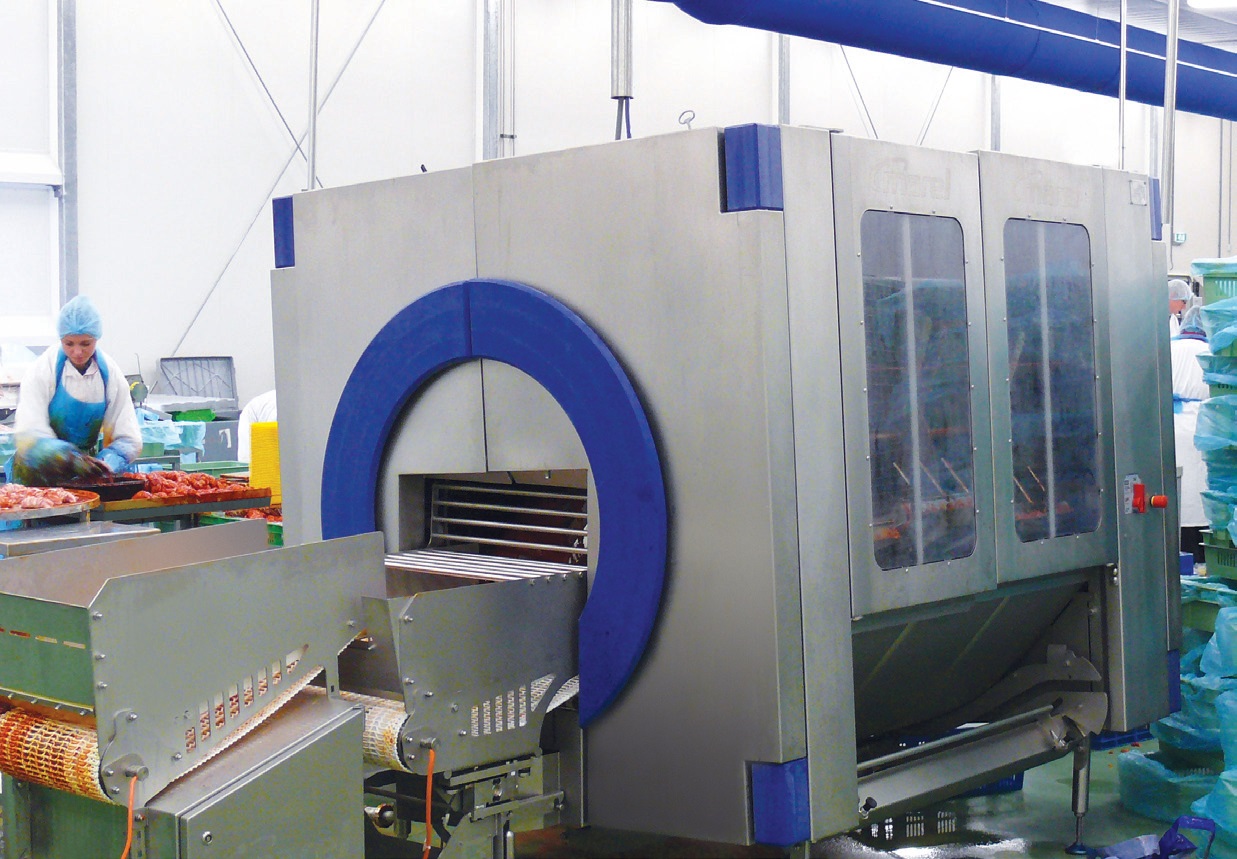

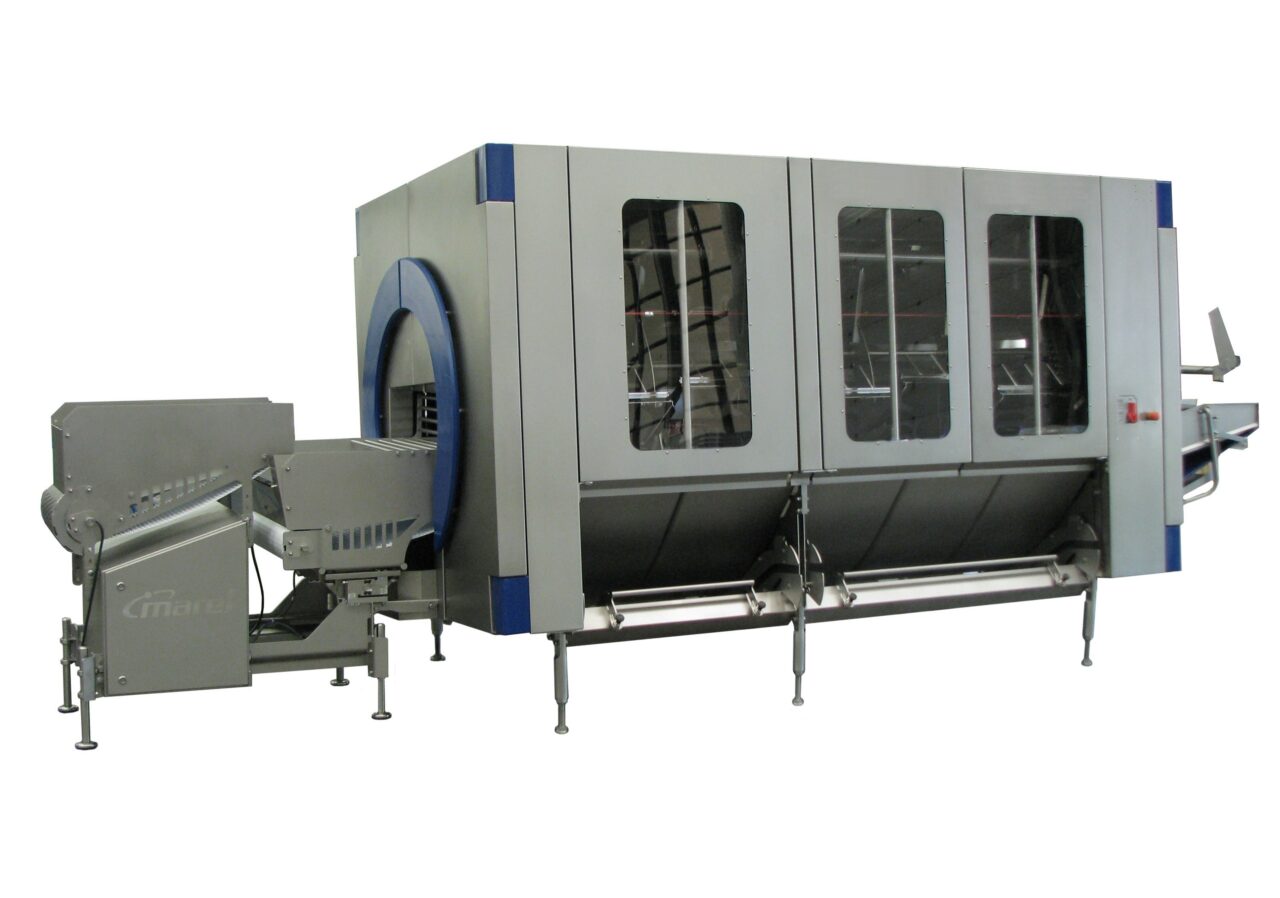

Unlike conventional tumblers which are loaded batch by batch and mainly by hand, ValueDrum features integrated inline production of coated or marinated fresh products. ValueDrum’s in-line principle of processing smaller portions with the possibility of applying specific massage components and the controlled method of adding different ingredients in a sequence, leads to a much more constant product quality.

Special Features

Highly accurate positioning