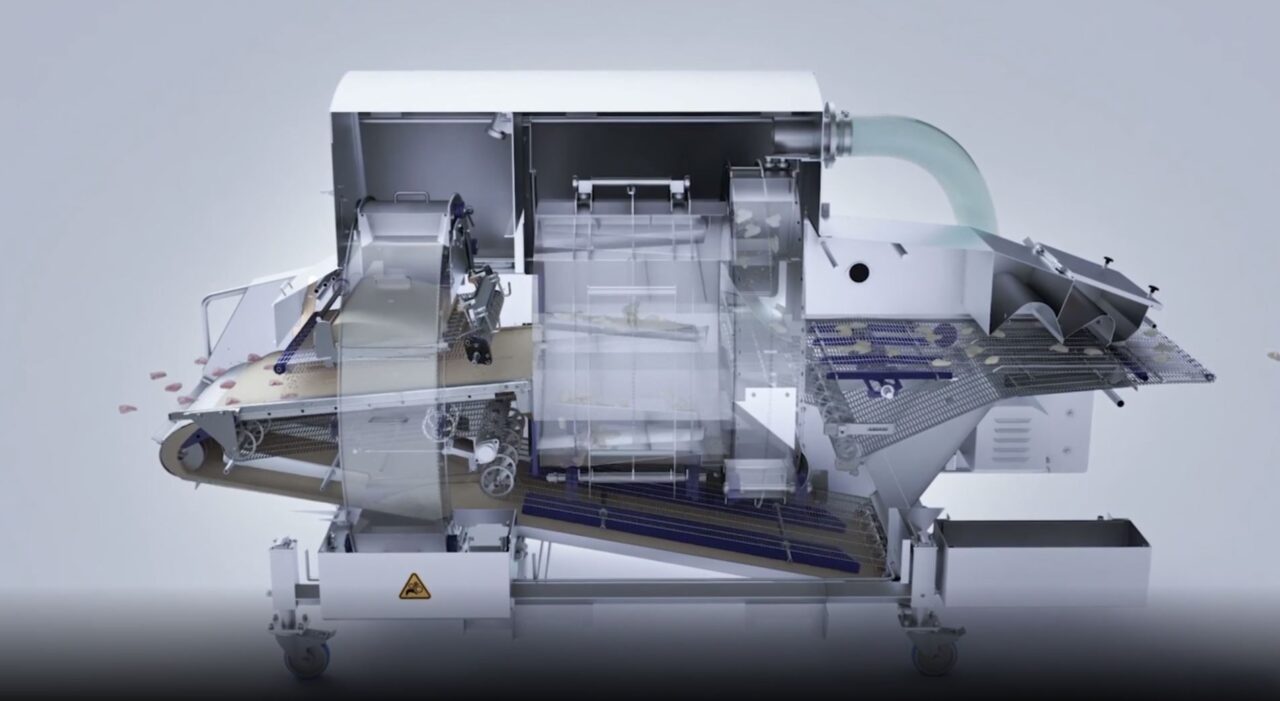

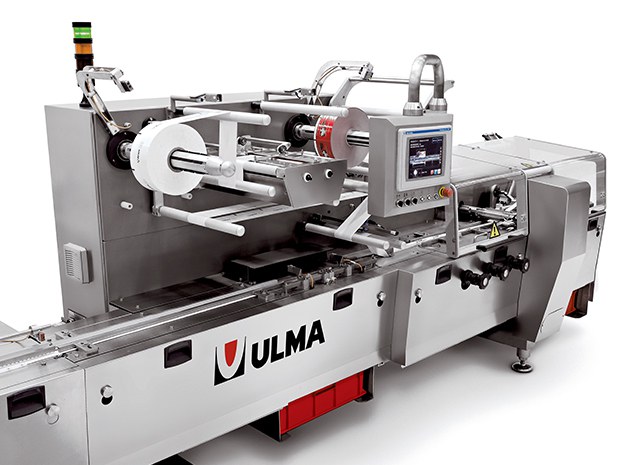

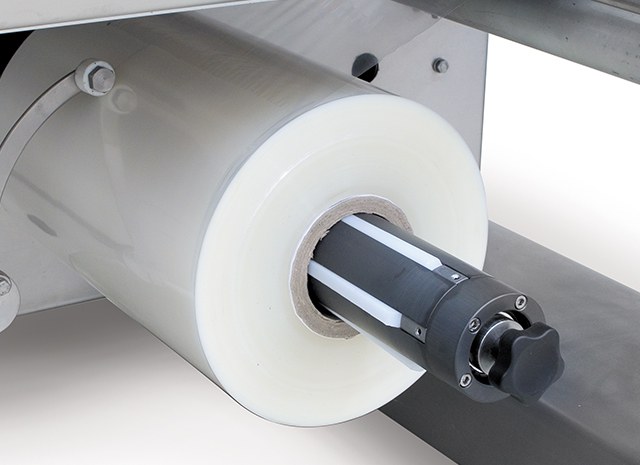

The FR 400 machine has been designed to be integrated into medium and high speed packaging systems. Its control system has also been designed for ease of operation and connectivity with other ancilliary and general productivity equipment.

Mainly focused on bakery, confectionery, and biscuit applications.

Special features

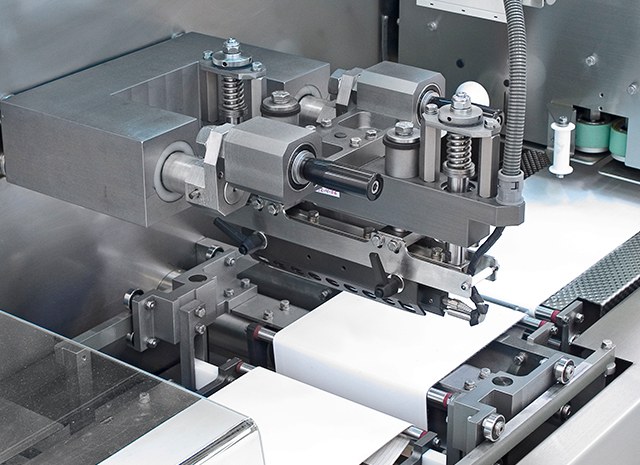

- Electronic machine equipped with independent servomotors

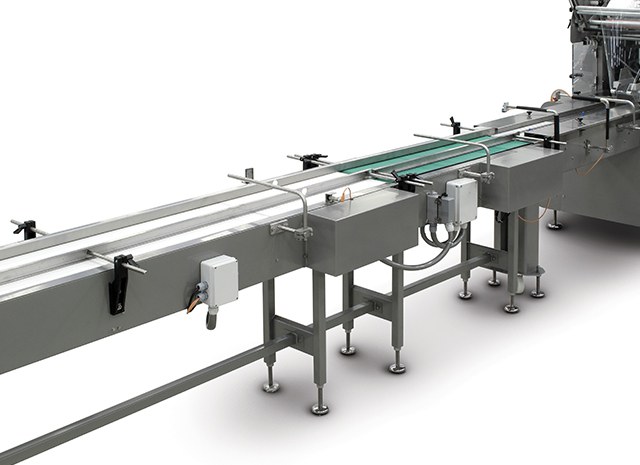

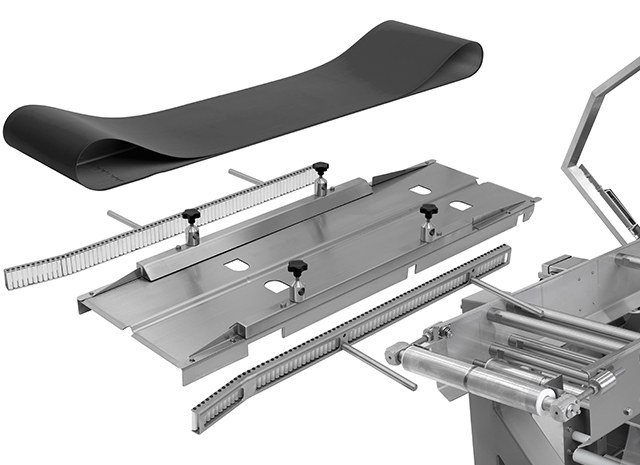

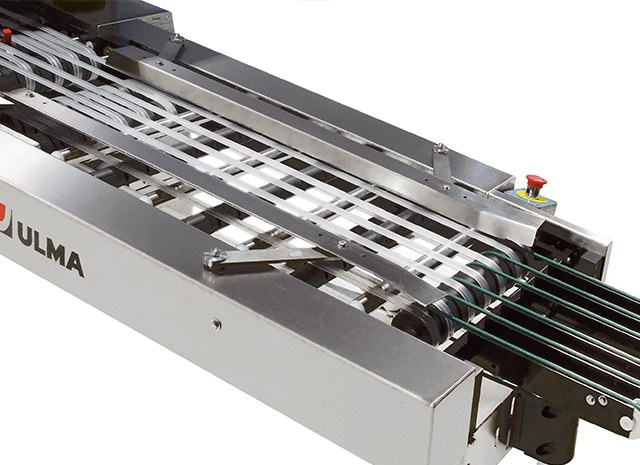

- Infeed conveyor with chain at one side to avoid dirt accumulation

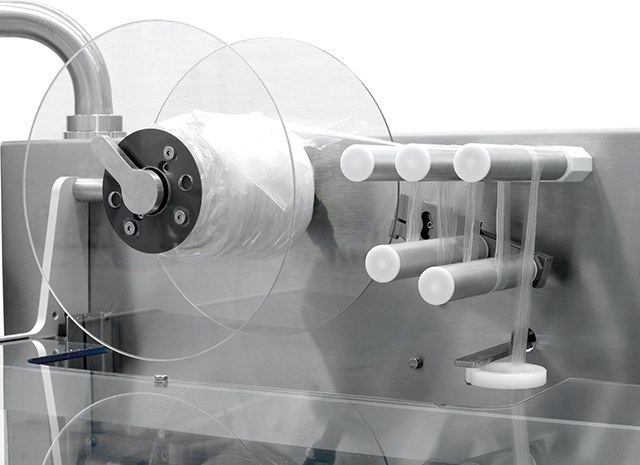

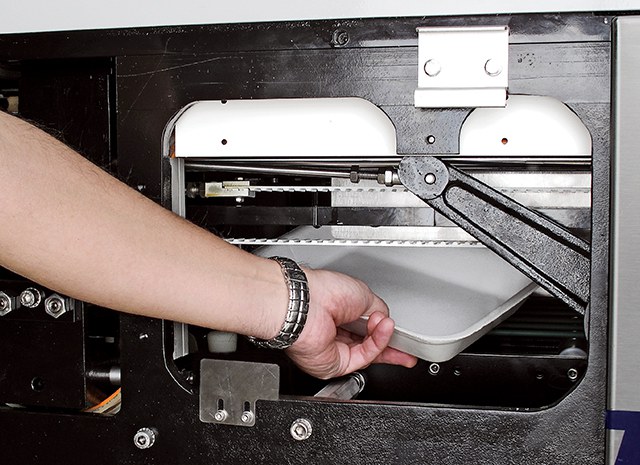

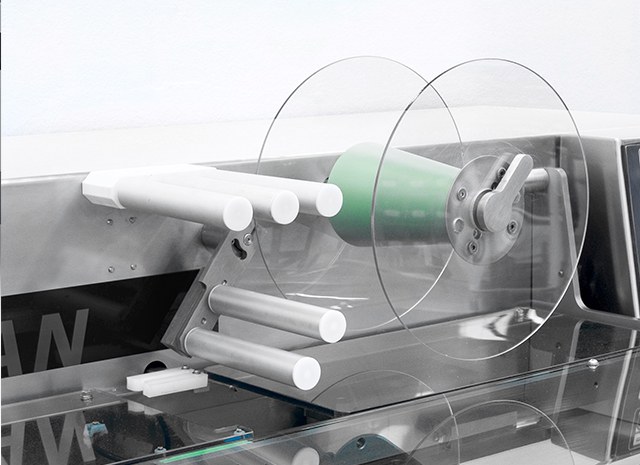

- Long sealing system by four pairs of sealing rollers with a tiltable first pair

- Motorized belt system at exit belt

- Empty and badly sealed package rejector

- 10″ touch screen

Additional information