Forming machine PlateFormer

High pressure forming machine of Marel of a variety of convenience products such as: meat balls, schnitzels, burgers, nuggets and whole pieces.

Special Features

Additional information

High pressure forming machine of Marel of a variety of convenience products such as: meat balls, schnitzels, burgers, nuggets and whole pieces.

Special Features

Additional information

The TG9 Tray Grader grades trays by fixed count, fixed weight or a combination of both.

Special Features

Additional information

System suitable for diverting the trays into fixed weight, fixed count or combination of both.

Special Features

Additional information

The Multi-Lane converger is suitable for converging products from multiple lines into one. Fully adjustable from 2 to six lines.

Special Features

Additional information

The Pack Turner turns packs to wide-edge leading to ensure the correct presentation when the pack reaches a labeler. This auxiliary unit integrates easily into a packing line, reducing manual handling and increasing line efficiency.

Additional information

MCheck 2 combines high levels of accuracy with flexibility and capacity, making it the ideal choice for any food processing company–both in wet and dry production environments and end-of-line applications.

150 packs/min up to 80 m/min 40-6000 kg 80x50x10 mm 589x350x125 mm 1,25 l/min 120 kg

Special Features

Technical Specifications

Productivity

Belt Speed

Weighing range

Minimum pack dimensions (LxWxH)

Maximim pack dimensions (LxWxH)

Air consumption

Weight

Additional information

Low pressure forming machine of Marel forfor producing products of uniform shape and accurate weight with high quality and productivity.

Special Features

Additional information

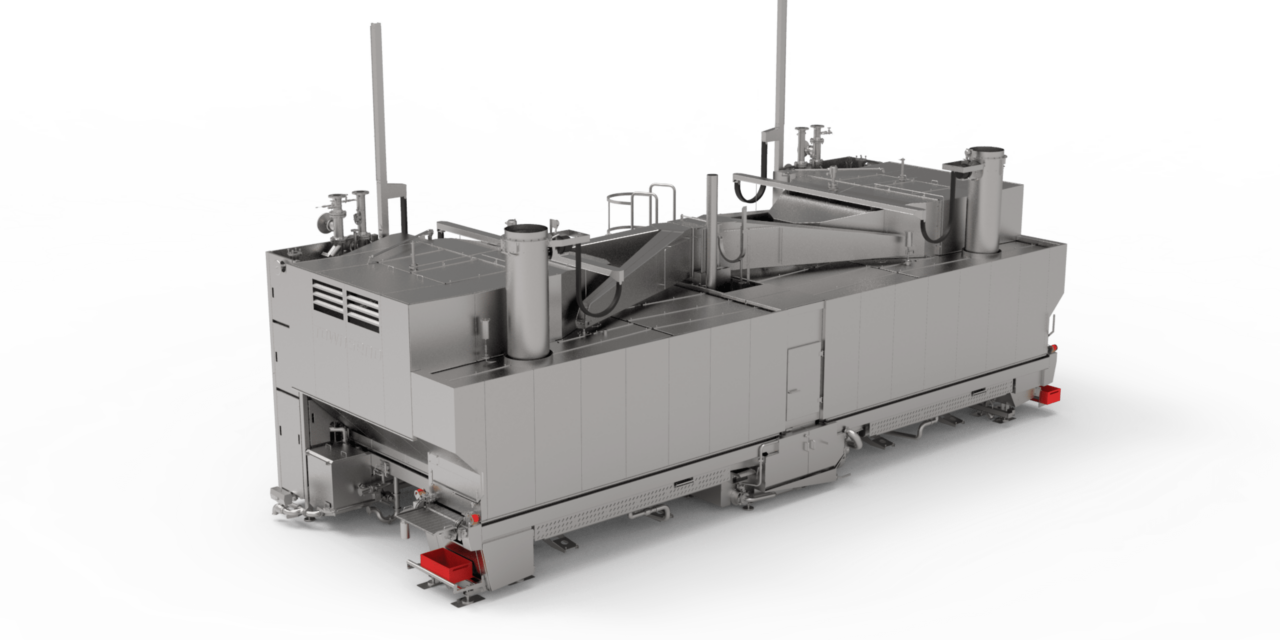

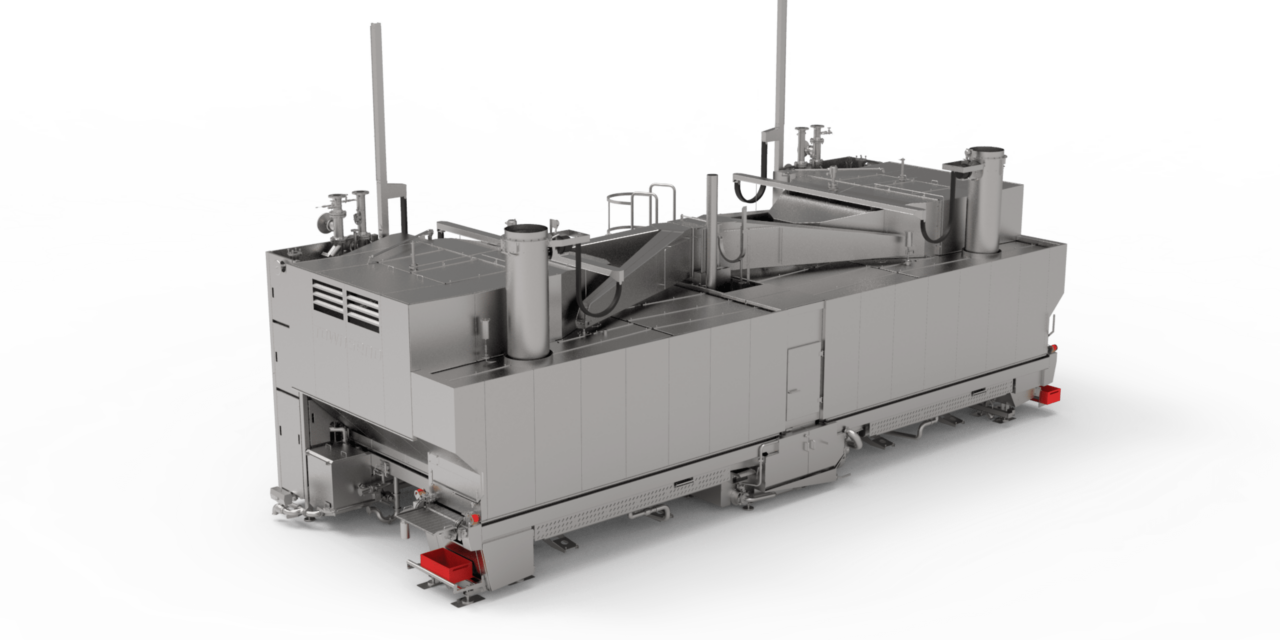

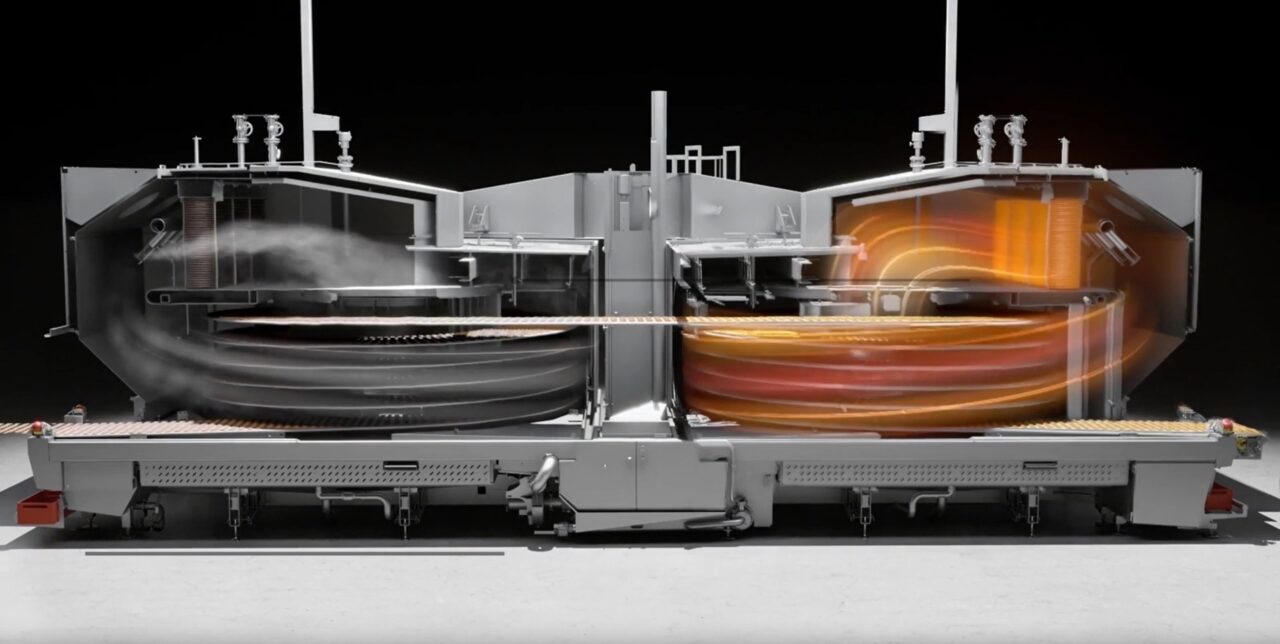

The ModularOven is Marel’s biggest oven system, consisting of two towers with separate controls for temperature, dew point and air speed, which offer the desired variable functionality for steaming, cooking or roasting in two completely separated climate zones.

Special Features

Additional information

The ModularOven+ is Marel’s biggest oven system, consisting of two towers with separate controls for temperature, dew point and air speed, which offer the desired variable functionality for steaming, cooking or roasting in two completely separated climate zones.

The ModularOven+ can be tailored to meet processors’ exact needs—now and into the future

LinearOven is suitable for the steaming, cooking, grilling and/or browning of all kinds of raw marinated products as well as cooked, baked or fried products.