Liquid smoke applicator Smoke-a-Matic. The Smoke-a-Matic can be used to smoke hot dogs, brats, cocktail sausages and other products. Its settings allow for total control of color and smoke flavor.

Special Features

Additional information

Liquid smoke applicator Smoke-a-Matic. The Smoke-a-Matic can be used to smoke hot dogs, brats, cocktail sausages and other products. Its settings allow for total control of color and smoke flavor.

Special Features

Additional information

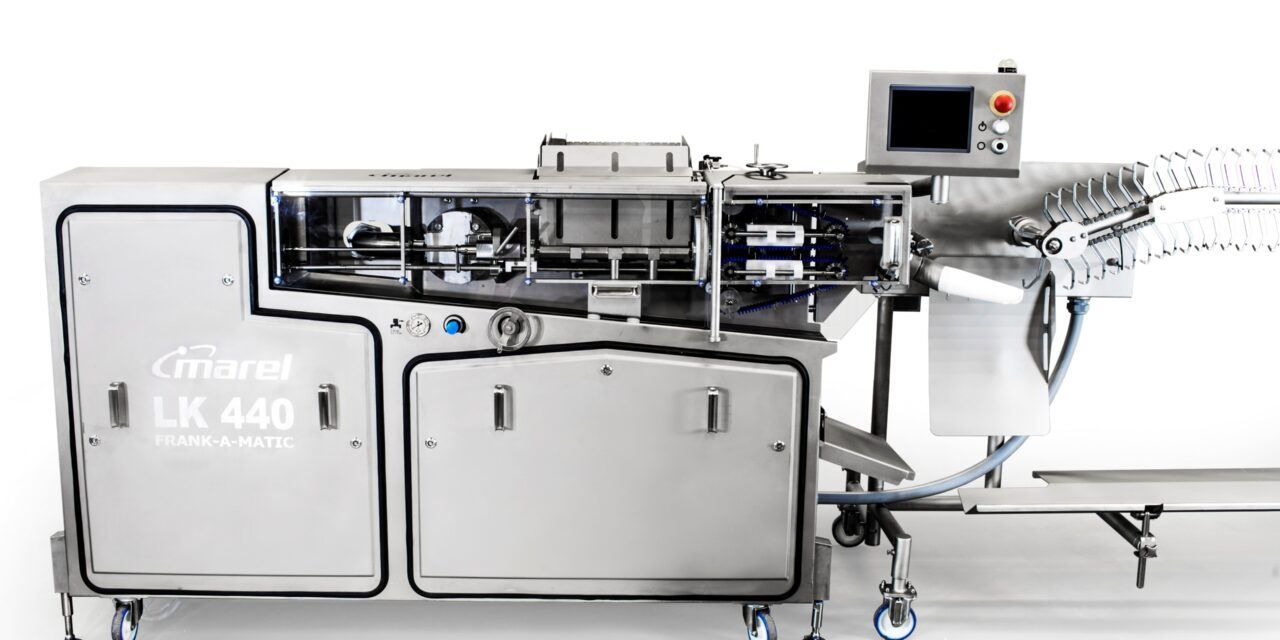

Sausage linker for filling, linking and hanging cellulose and collagen casing.

Cellulose/Polyamide Collagen 14-34 mm 14-34 mm 60-360 mm 60-360 mm 3000 kg/h 1500 kg/h 430/530 mm 430/530 mm

Special Features

Technical Specifications

Casing

Sausage caliber range

Sausage length range (in 10 mm increments)

Maximum machine capacity

Casing slug length, max

Additional information

The FlexLinker produces sausages with collagen or cellulose casing fully automatically. Sausages with natural casing are produced semi-automatically. In one continuous movement, the FlexLinker produces strings of sausages of a constant length and weight per sausage. This continuous linking results in less loss of raw material.

Special Features

Additional information

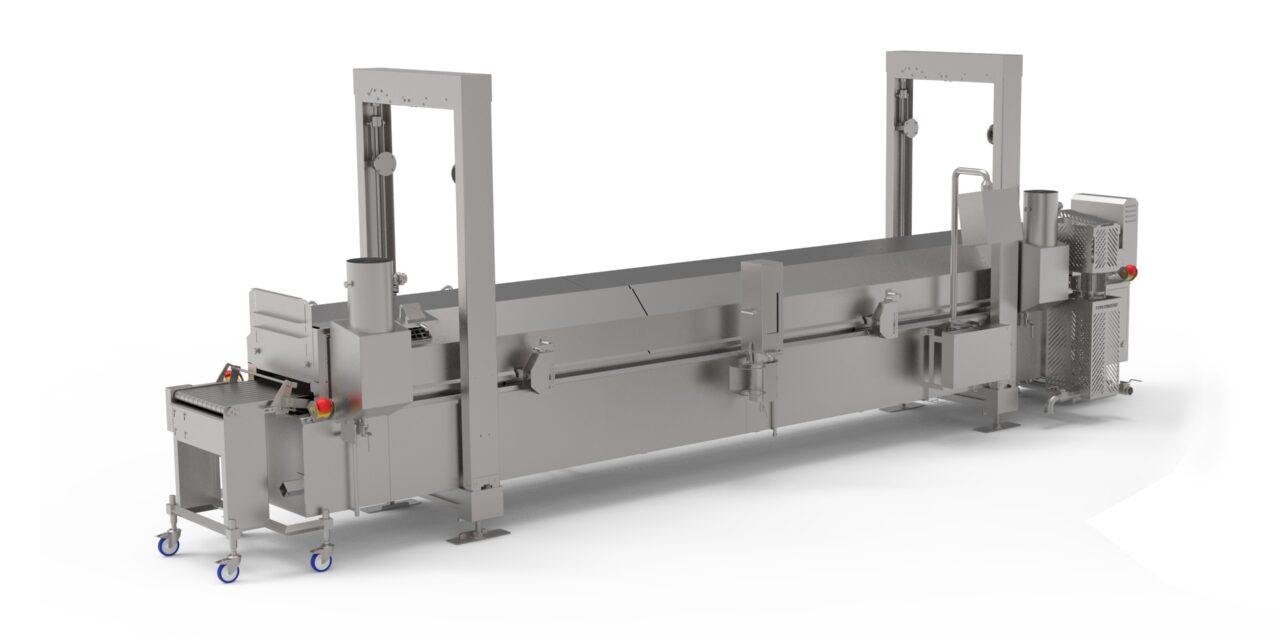

GoldFryer produces a beautifully fried end product with an attractive color, perfect coating adhesion and enhanced taste and texture. The oil flow in the GoldFryer has the highest circulation speed in the industry. This ensures a highly stable frying environment and maximum transfer of heat to products.

Special Features

Additional information

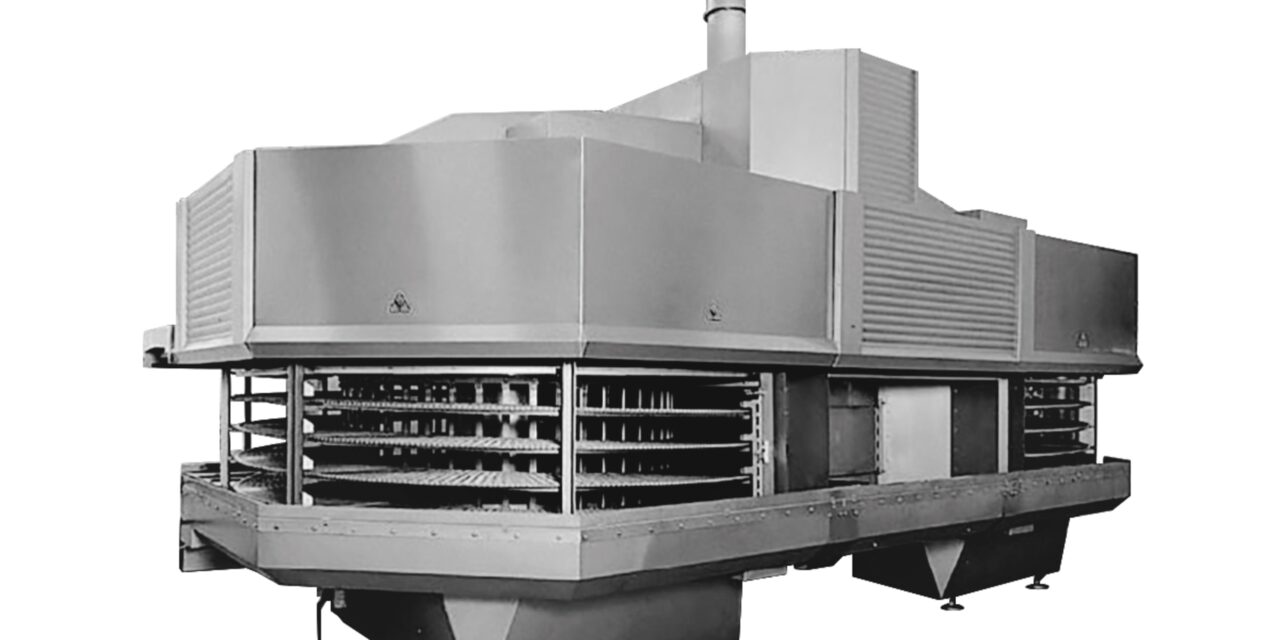

The Marel spiral oven is suitable for steaming, cooking and baking a wide range of products.

Special Features

Additional information

M2 series is both hygienic in production and easy to clean and offers various sizes of injectors depending on width of the transport systems Intuitive settings of pump pressure and production speed together with a constant read-out of brine temperature allows for precise and optimum food production.

Special features

Additional information

The M3 comes in four different sizes, each with a different number of head configurations available, allowing for total customization. Due to the modular design, identical programs and because the exact same construction principles have been applied to all components and controls, installation and use have never been easier.

Special features

Additional information

Oscar 20 is an automatic and hydraulic stuffer. It is portable and flexible to be placed anywhere in production. In addition to the production of classic cold cuts and sausages, the Oscar 20 is often used for delicatessens production.

Special Features

Technical Specifications

Cylinder Capacity

20 l

Gross Weight

150 kg

Power

0,75 kW

Power Supply

400V, 50Hz, 3phase

Dimensions (HxLxW)

105x50x60 cm

Additional information

MF 30-4 is 30 liters piston stuffer for straight filling. It was designed and built CE-conform according the strict safety and hygiene requirements of the CE-regulations.

Special Features

Technical Specifications

Cylinder Capacity

30 l

Gross Weight

300 kg

Ισχύς

1,1 kW

Power Supply

400V, 50Hz, 3phase

Additional information

The Kompakta 2 works like a straight filling, portioning and linking machine. The wide and extremely short outlet cares for a good finish for filling coarse meat and especially sausage meat.

Special features

Technical Specifications

Cylinder capacity

30l

Gross Weight

300 kg

Power

3,3 kW

Power Supply

400V, 50Hz, 3phase

Processing quantity

Up to 250 portions/min

Additional information