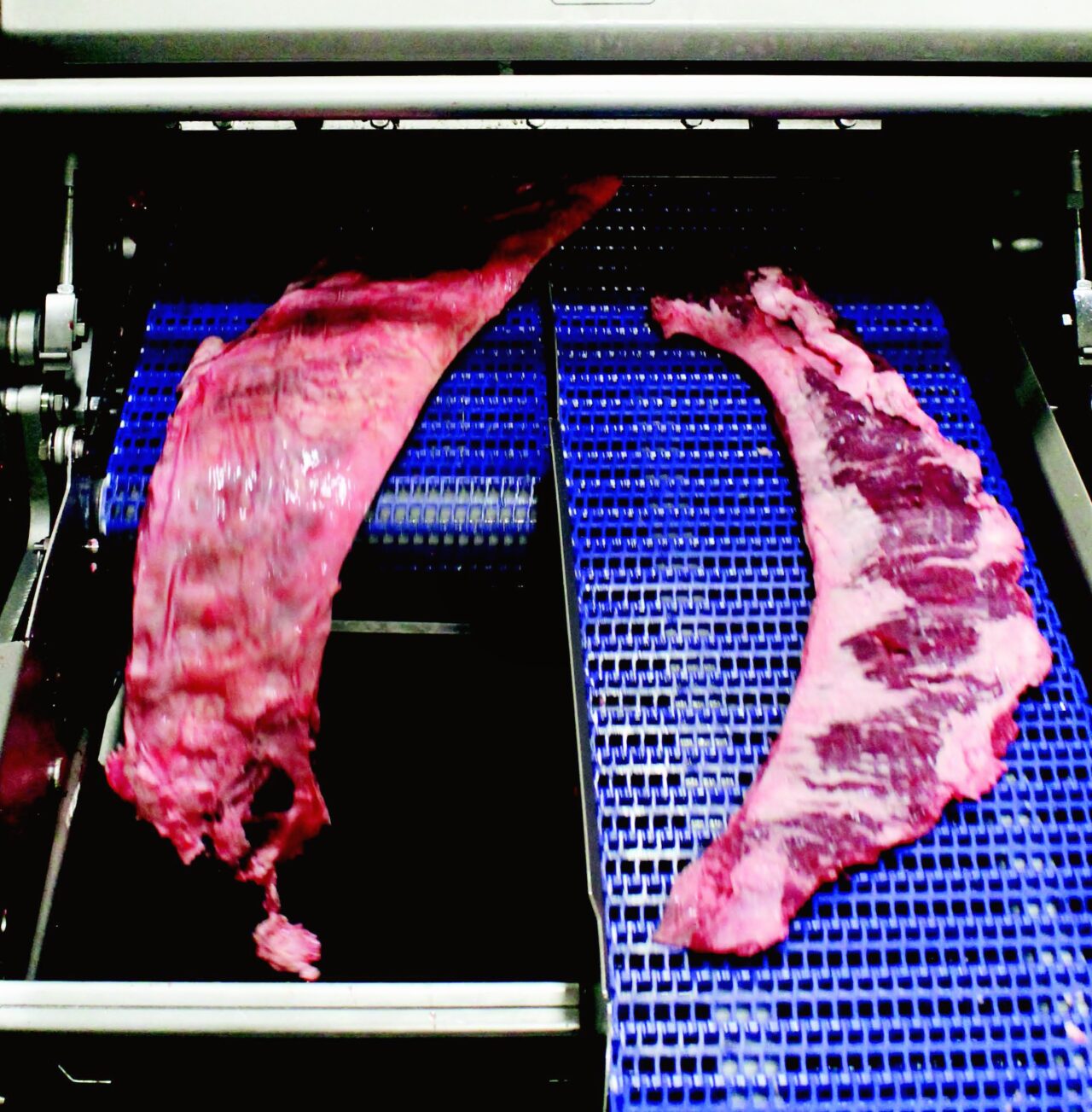

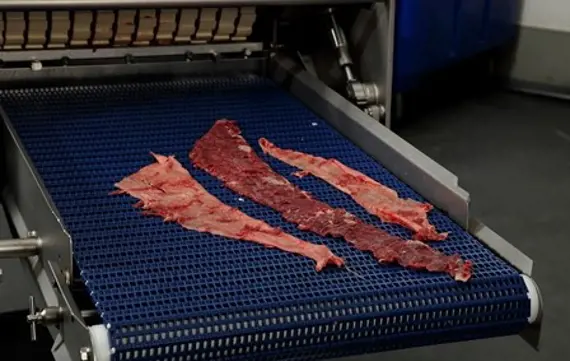

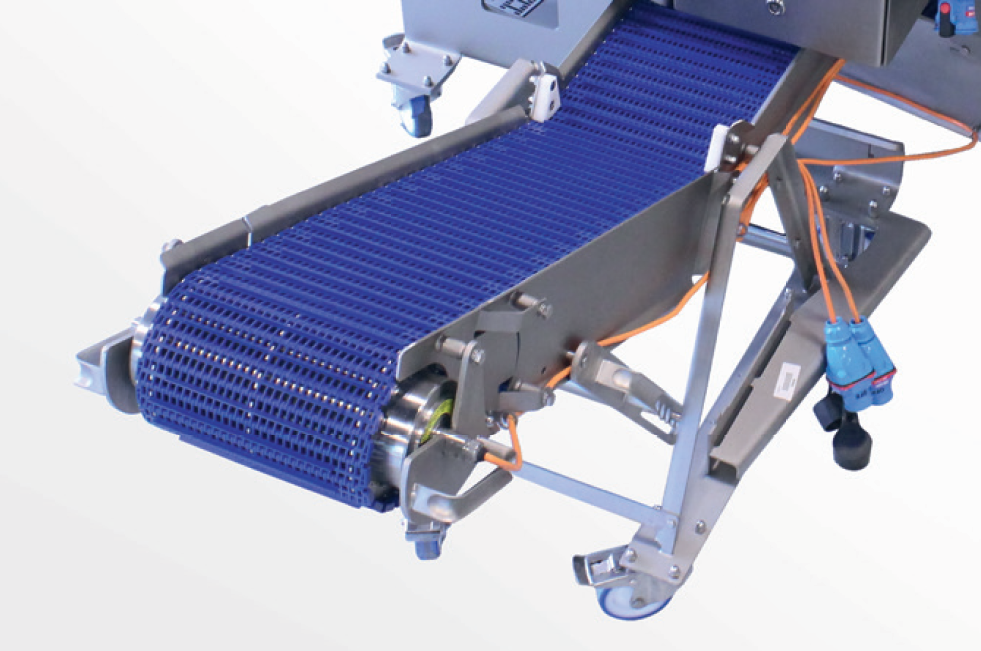

The EVM range is designed for open-top membrane skinning of any type of fresh meat cuts. It’s available in two cutting widths to offer the ideal skinning solution both for small and medium-sized processors and for industrial processors.

EVM 5004 EVM 5006 434 mm 554 mm 826x760x1005 mm 946x760x1005 mm 0,55 kW 0,55 kW 190 kg 200 kg

Special Features

Special Features

Version

Cutting width

Dimensions (LxWxH)

Power

Weight

Additional information