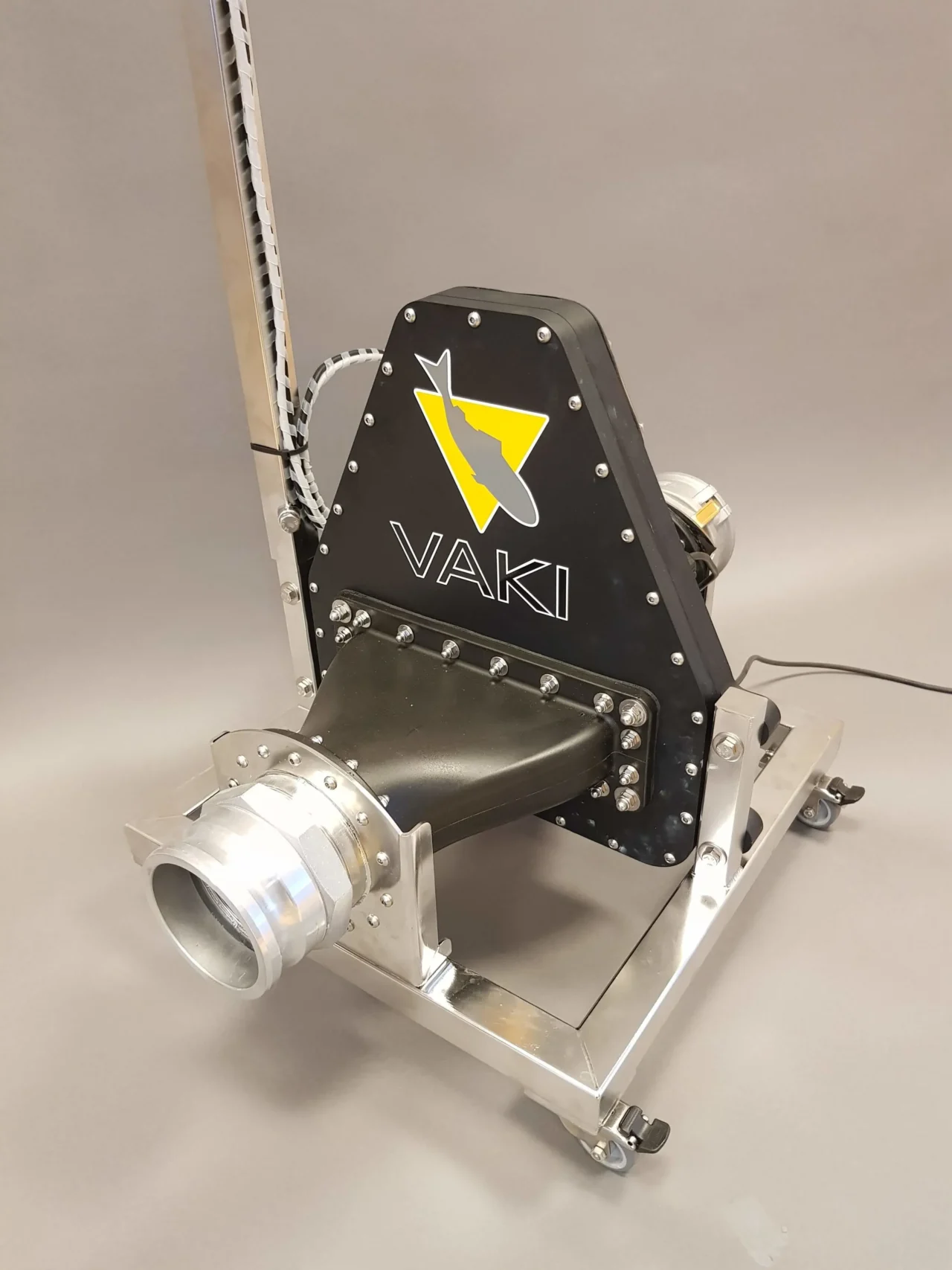

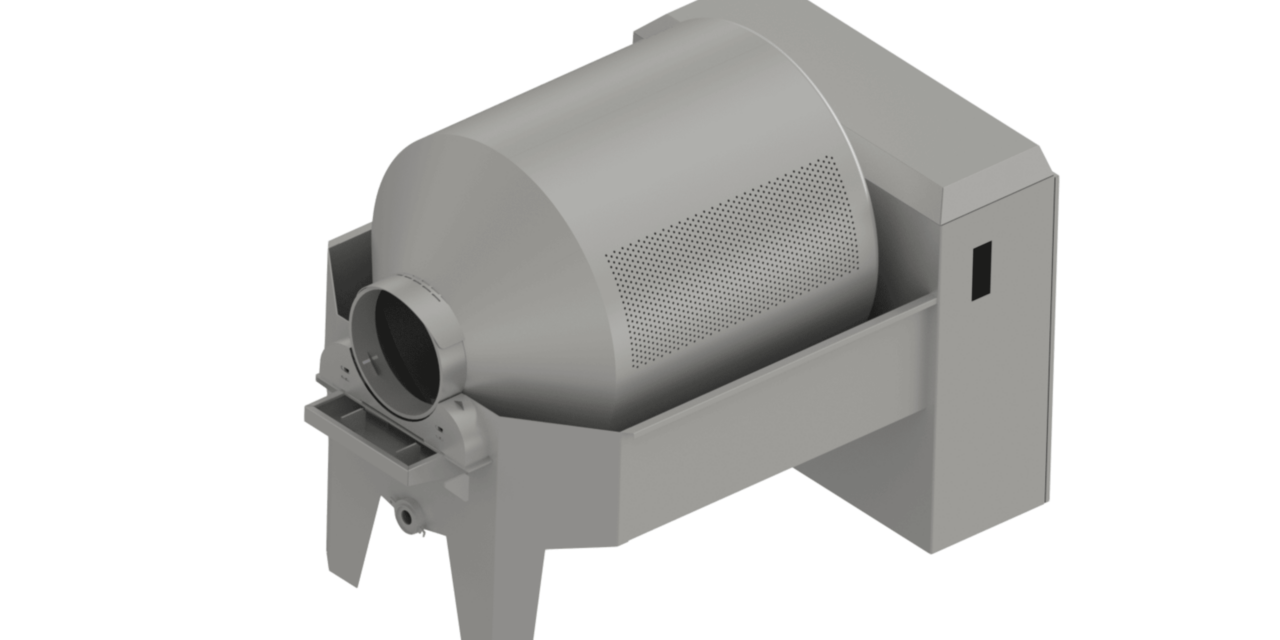

The VAKI Nano Counter provides commercial aquaculture operators with highly-accurate counting of fish from as small as 0.05g. The Nano Counter has very high capacity 200,000 fish per hour at 1g size.

0,05 – 30 g 200000 fish/hour 99% 1500x700x1600 mm

Special Features

Technical Features

Fish size

Capacity for fish 1g

Accuracy

Dimensions (LxWxH)

Additional information