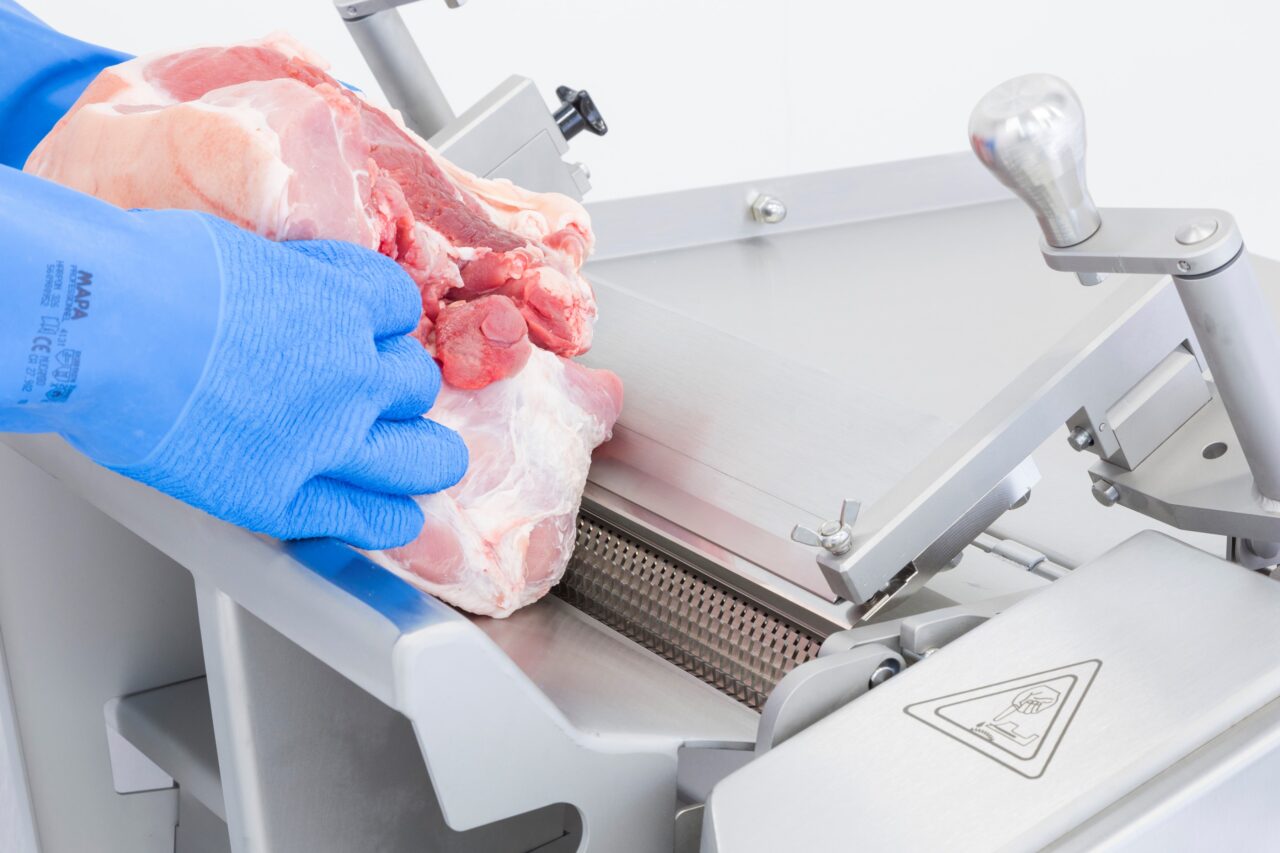

The MAJA ESM 5550 is designed for open-top derinding of round-shaped pork cuts, e.g. ham and shoulder, with and without bones.To allow the simultaneous removal of rind and fat, the MAJA ESM 5550/1 is equipped with a twin knife holder, so that boneless cuts can be derinded and defatted in any thickness in one step. The removed rind and fat leave the machine separately and do not need to be sorted, which saves labor.

- Combined derinding and defatting solution

- Geometry of the defatting knife holder allows power-saving defatting, even with big and heavy meat cuts

- Tool-free changeover of the machine to another type of cut: The work tables, work table support and the MAJA ESM 5550/1 ‘s defatting knife holder can be quickly exchanged without tools and dismounted for cleaning

- No removal for cleaning and changing of the derinding knife holder: It remains in the machine and is only put into cleaning position

- Fast and easy changing and adjustment of the derinding knife, tool-free with quick-locking device

- User friendly operation

|

Maja ESM 5550

|

Maja ESM 5550/1 |

Maja ESM 5800

|

| Cut-off length |

554 mm

|

554/530 mm |

800 mm

|

| Dimensions |

1027×830-860×999 mm

|

1027×795-824×1210 mm |

1273×795-824×1021-1048 mm

|

| Power |

0,75 kW

|

0,75 kW |

0,75 kW

|

| Weight |

178 kg

|

205 kg |

215 kg

|

|

Maja ESM 5550

|

| Cut-off length |

554 mm

|

| Dimensions |

1027×830-860×999 mm

|

| Power |

0,75 kW

|

| Weight |

178 kg

|

|

Maja ESM 5550/1

|

| Cut-off length |

554/530 mm

|

| Dimensions |

1027×795-824×1210 mm

|

| Power |

0,75 kW

|

| Weight |

205 kg

|

|

Maja ESM 5800

|

| Cut-off length |

800 mm

|

| Dimensions |

1273×795-824×1021-1048 mm

|

| Power |

0,75 kW

|

| Weight |

215 kg

|