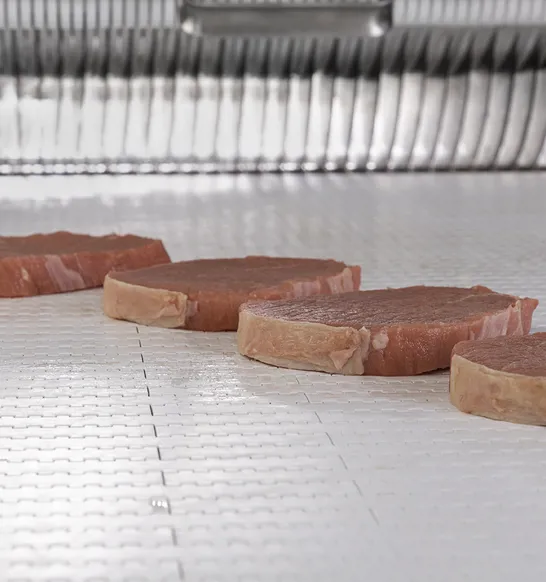

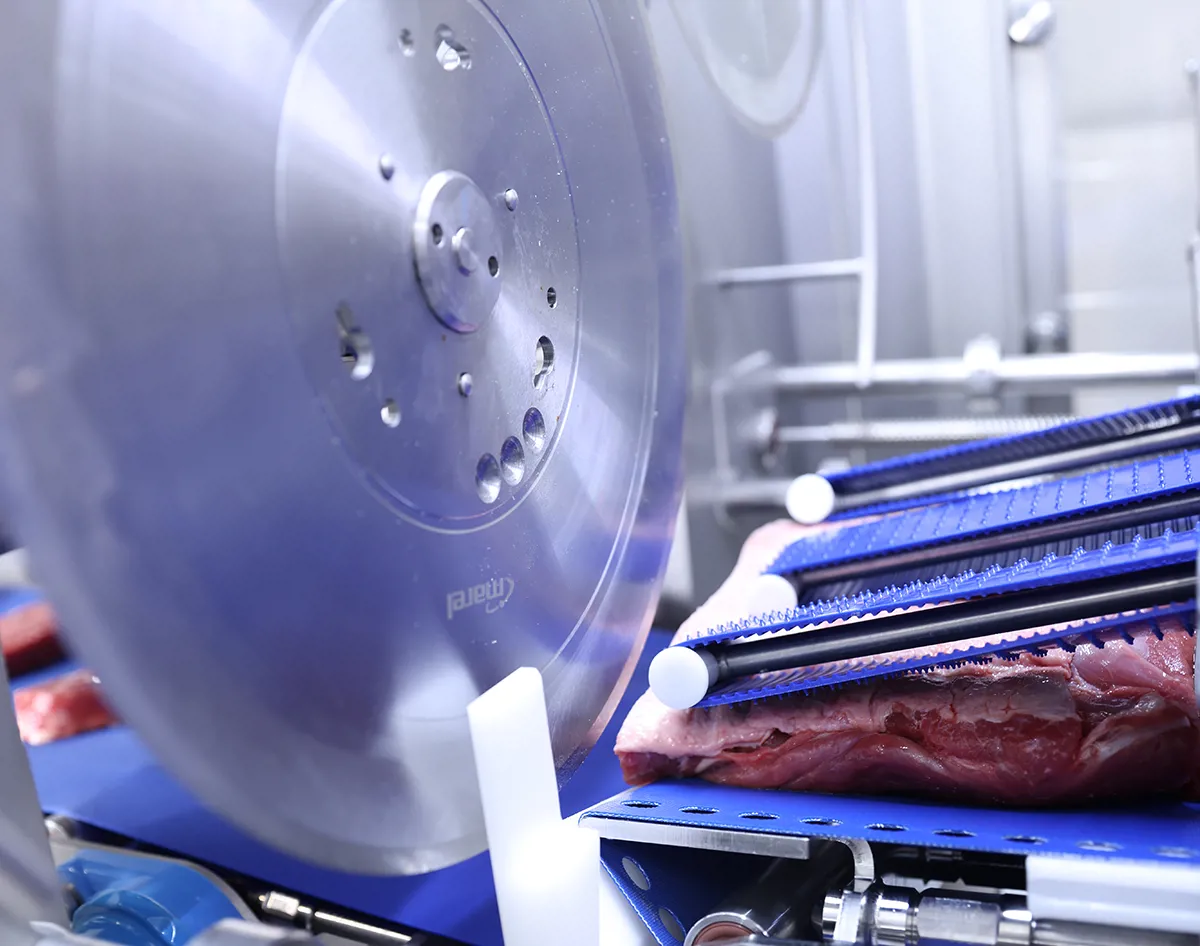

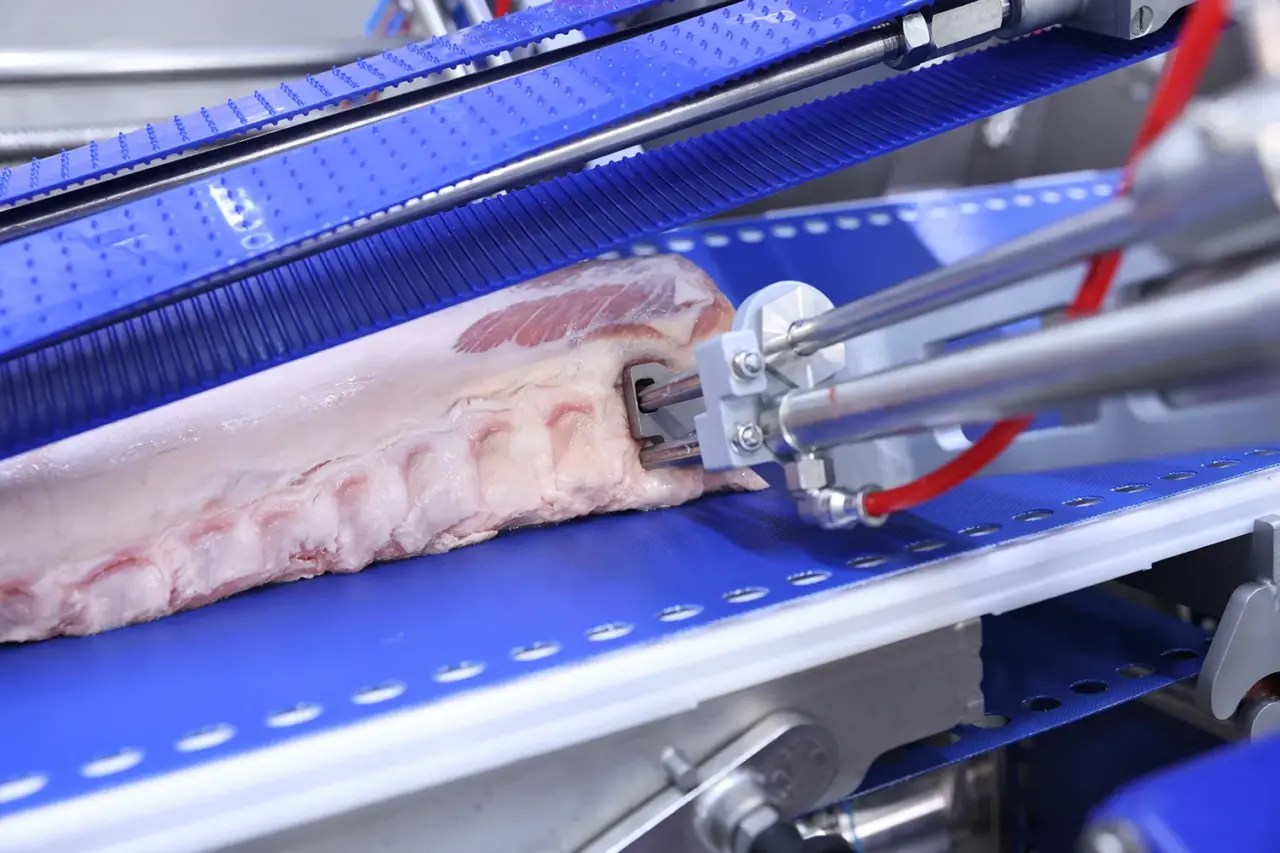

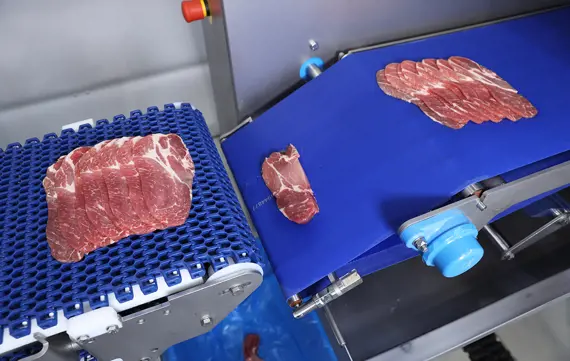

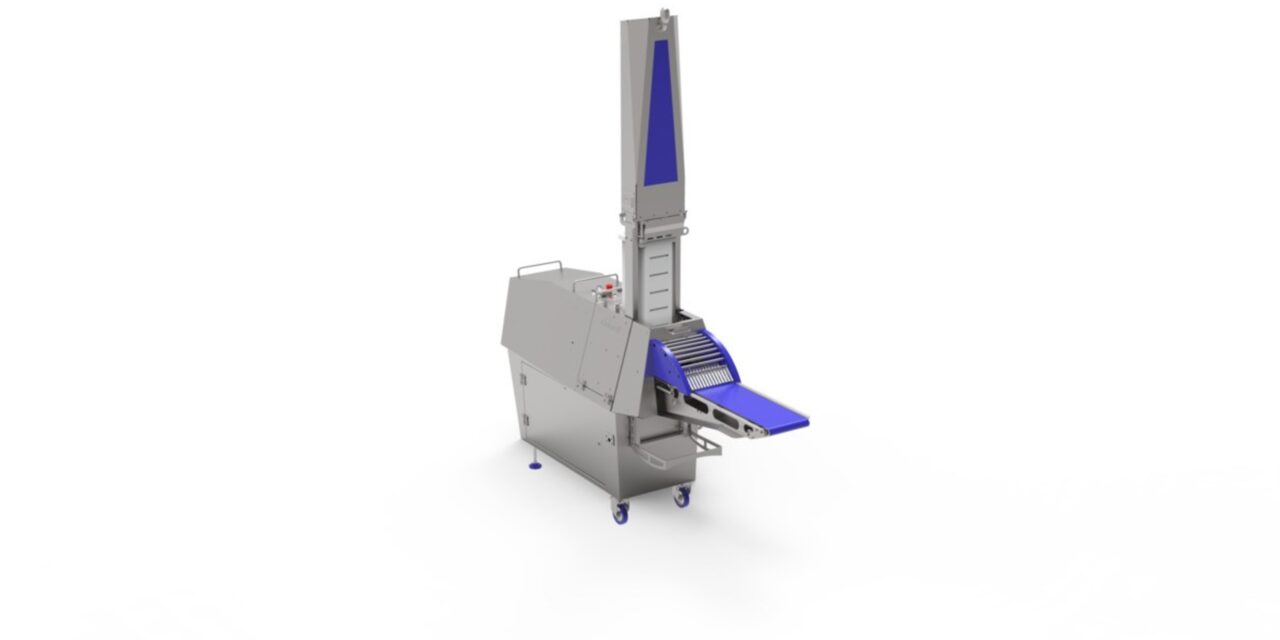

The I-CUT 610 is suitable for processing non-frozen boneless meat products to fixed weight and/or uniform dimensions. The Marel cutting machine offers high speed and precision in combination with modern cutting processing software. The I Cut 610 is a flexible tool suitable for all needs and throughputs.

1240x250x150 mm 1200 cuts/min per lane 20-500 mm/s 3300x1700x1600 mm

Special Features

Technical Specifications

Maximum product dimensions (LxWxH)

Maximum machine capacity

Belt Speed

Machine dimensions (LxWxH)

Additional information