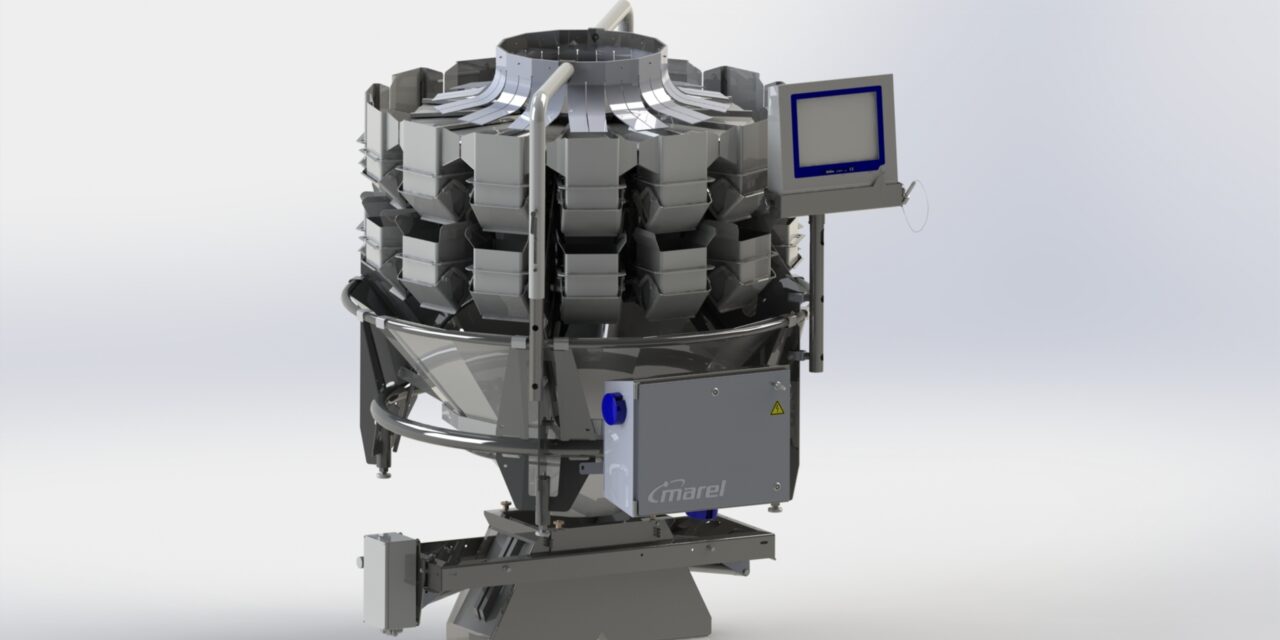

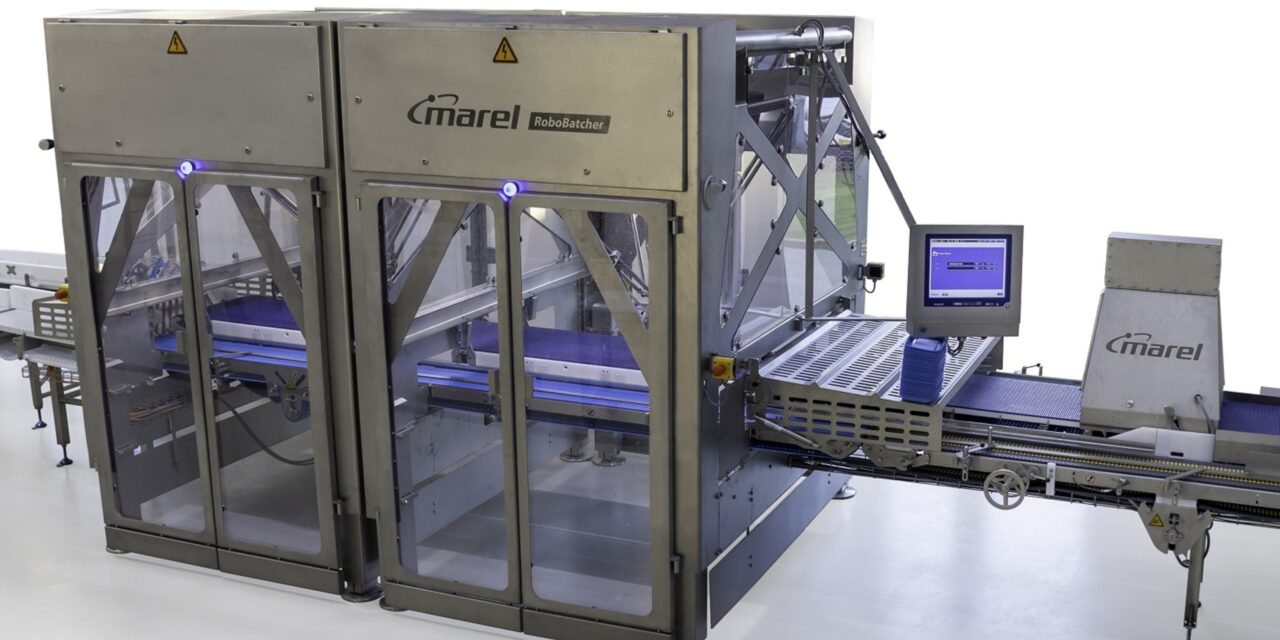

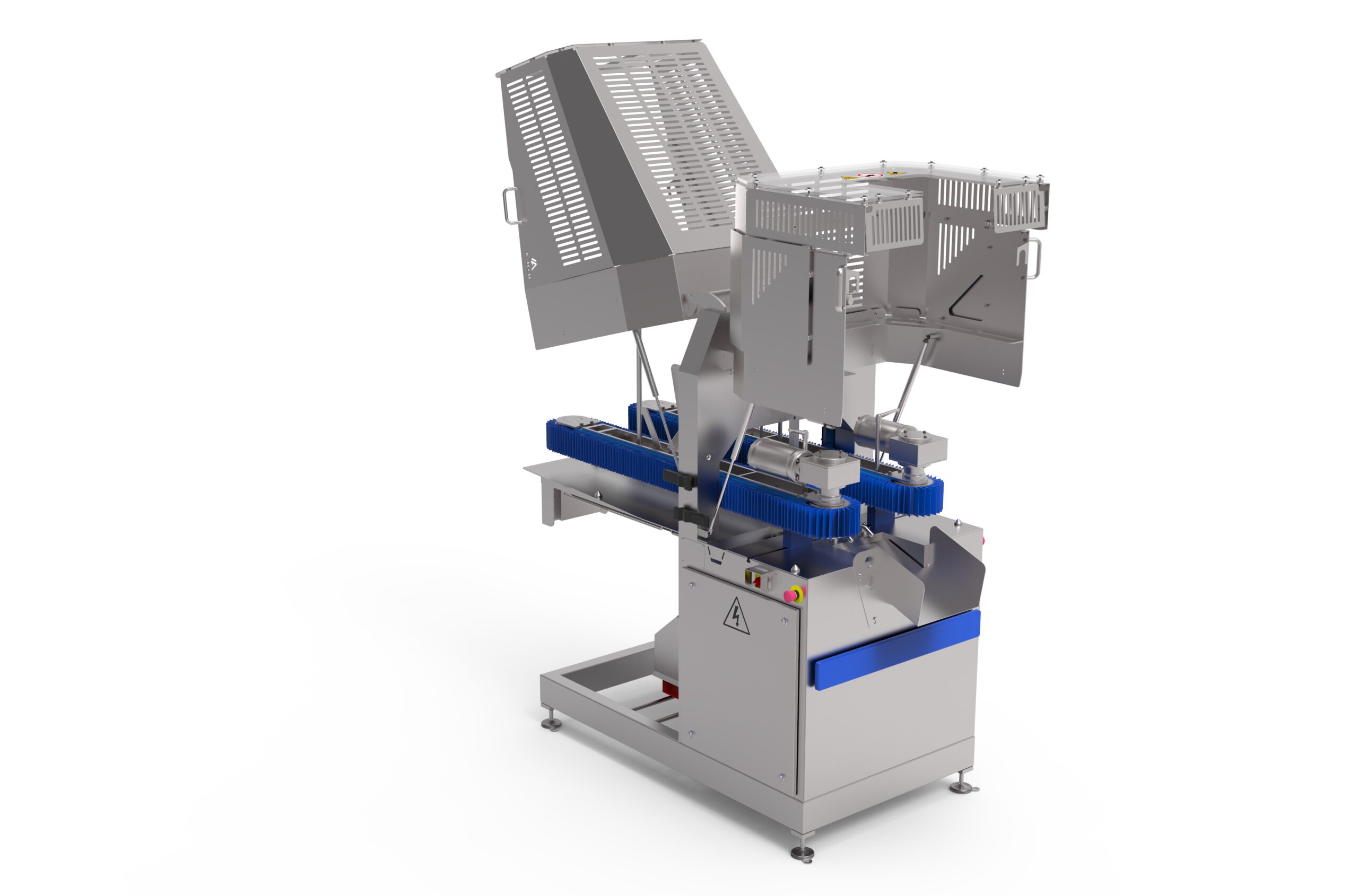

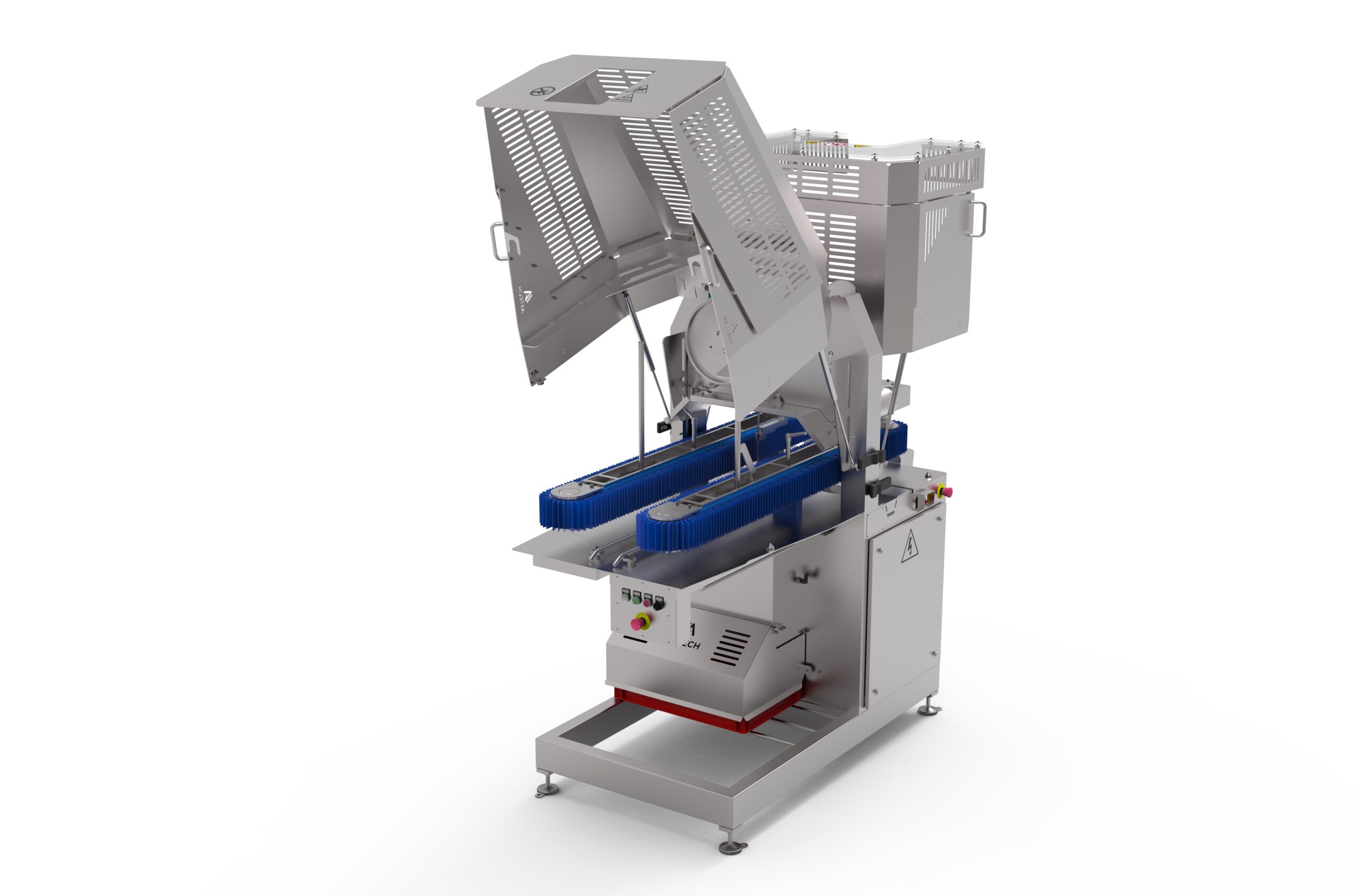

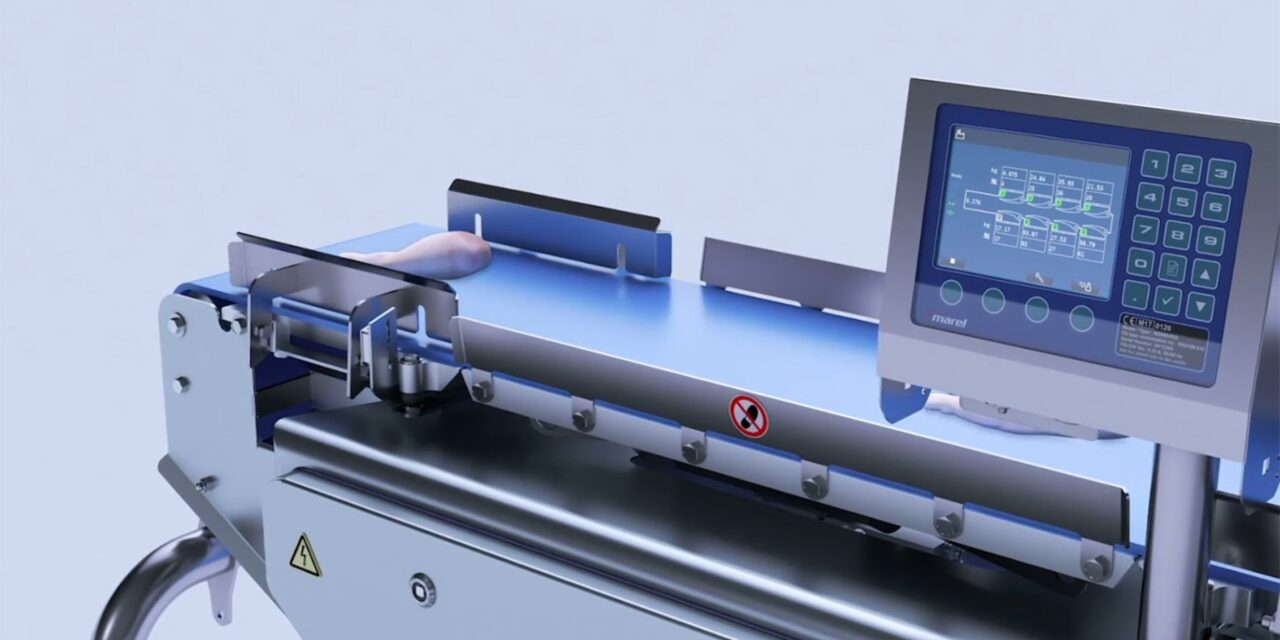

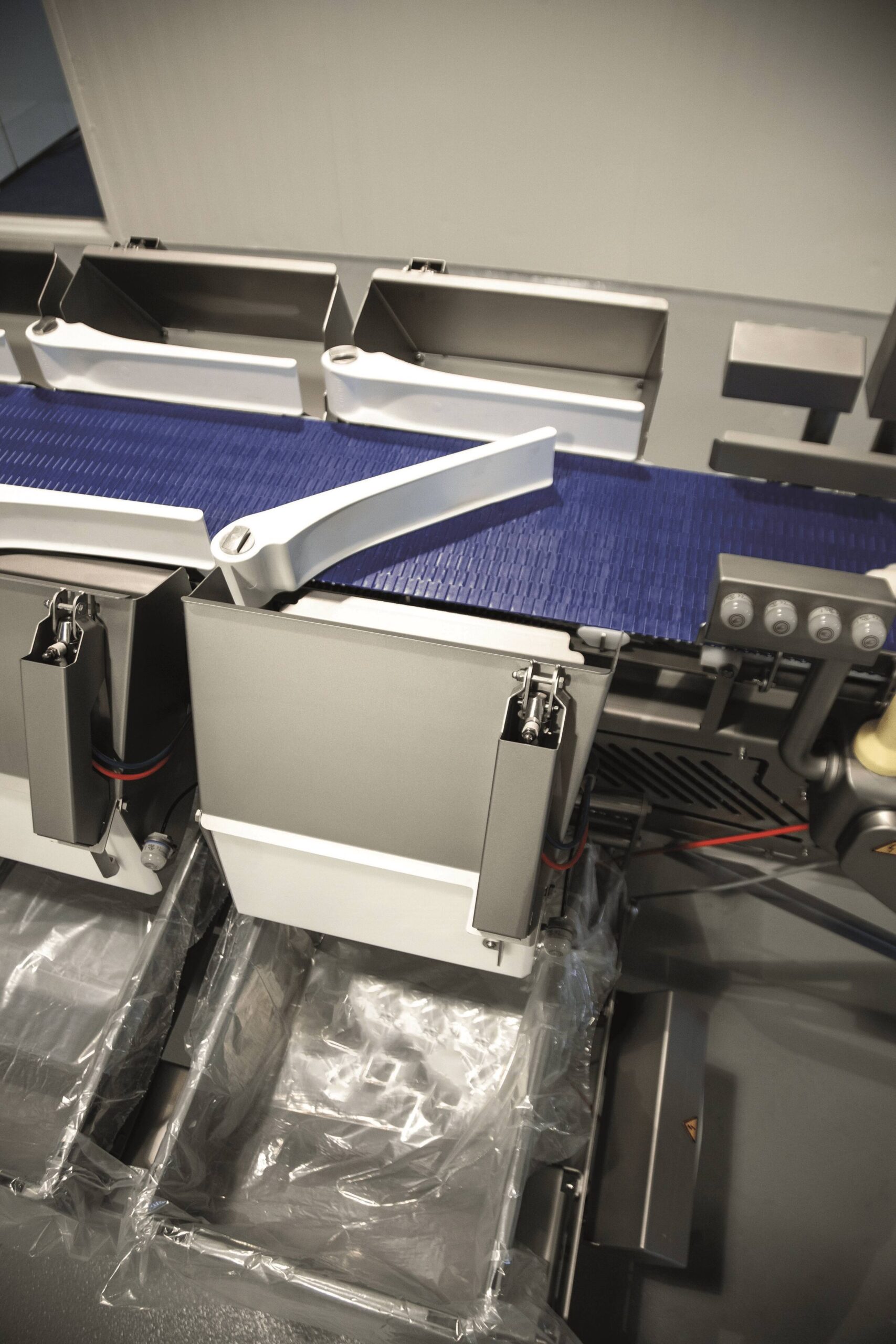

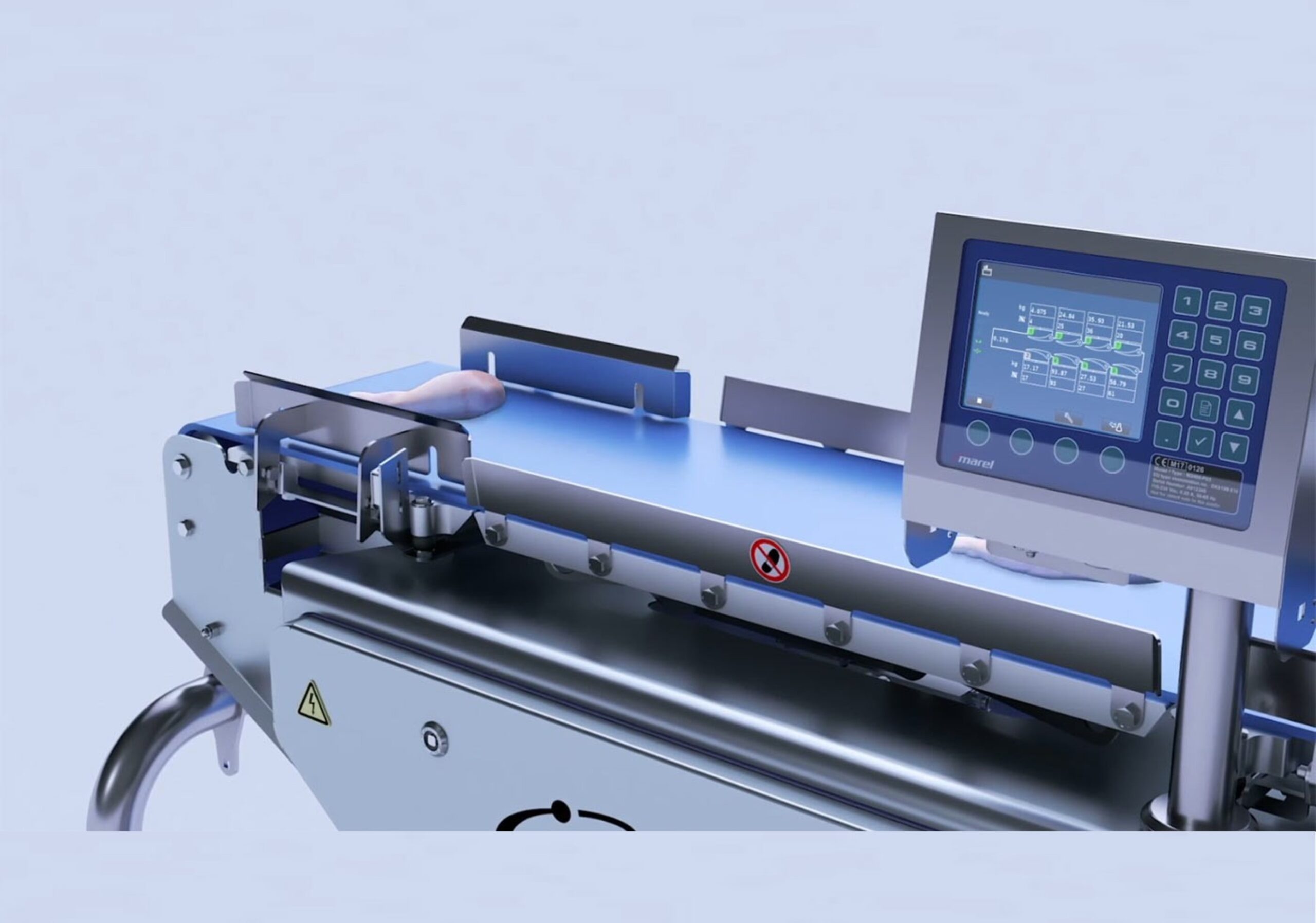

The Marel Compact Grader is used for weighing and sorting in a continuous flow of products. The weight of each piece is weighed on the belt and the arms advance it into packaging based on the set program on the sorting screen. The Compact Grader has benches on the left and right side for placing styrofoam, boxes, etc.

CG450 CG900 2×3 or 2×4 2×3 250 mm 700 mm 250 mm 250 mm 40-1500 g 100-6000 g 160 pcs/min 80 pcs/min

Special Features

Technical Specifications

Version

CG600

Gates

2×3 or 2×4

Max. product length

400 mm

Max. product width

250 mm

Weight range

40-3000 g

Maximum machine capacity

120 pcs/min

Additional information