The wardrobe has a large number of clothes hooks for simple hanging up of clothing. The wardrobe has adjustable feet and is entirely made from stainless steel.

The wardrobe has a large number of clothes hooks for simple hanging up of clothing. The wardrobe has adjustable feet and is entirely made from stainless steel.

The hand dryer Dyson Airblade™ has ergonomic design and it is fast. It filters the air before it reaches the hands. In just 10 seconds the water is removed from your hands. The Dyson Airblade™ uses up to 80% less energy.

The most effective hand dryer is the Dyson Airblade V™. This hand dryer cleans the air before it is blown onto the hands. In just 10 seconds, the water is removed from your hands by a ‘blade of air’. The Dyson Airblade V™ is extremely compact for its type. It does not need to be built in and projects only 10 cm from the wall. The HEPA H12 filter enables the Airblade™ to remove up to 99.9% of the bacteria present.

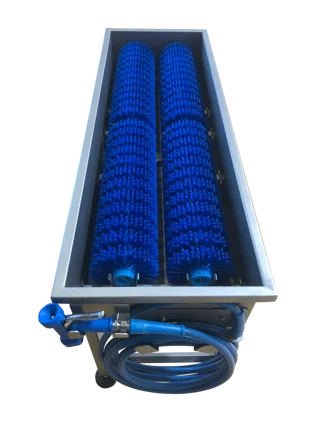

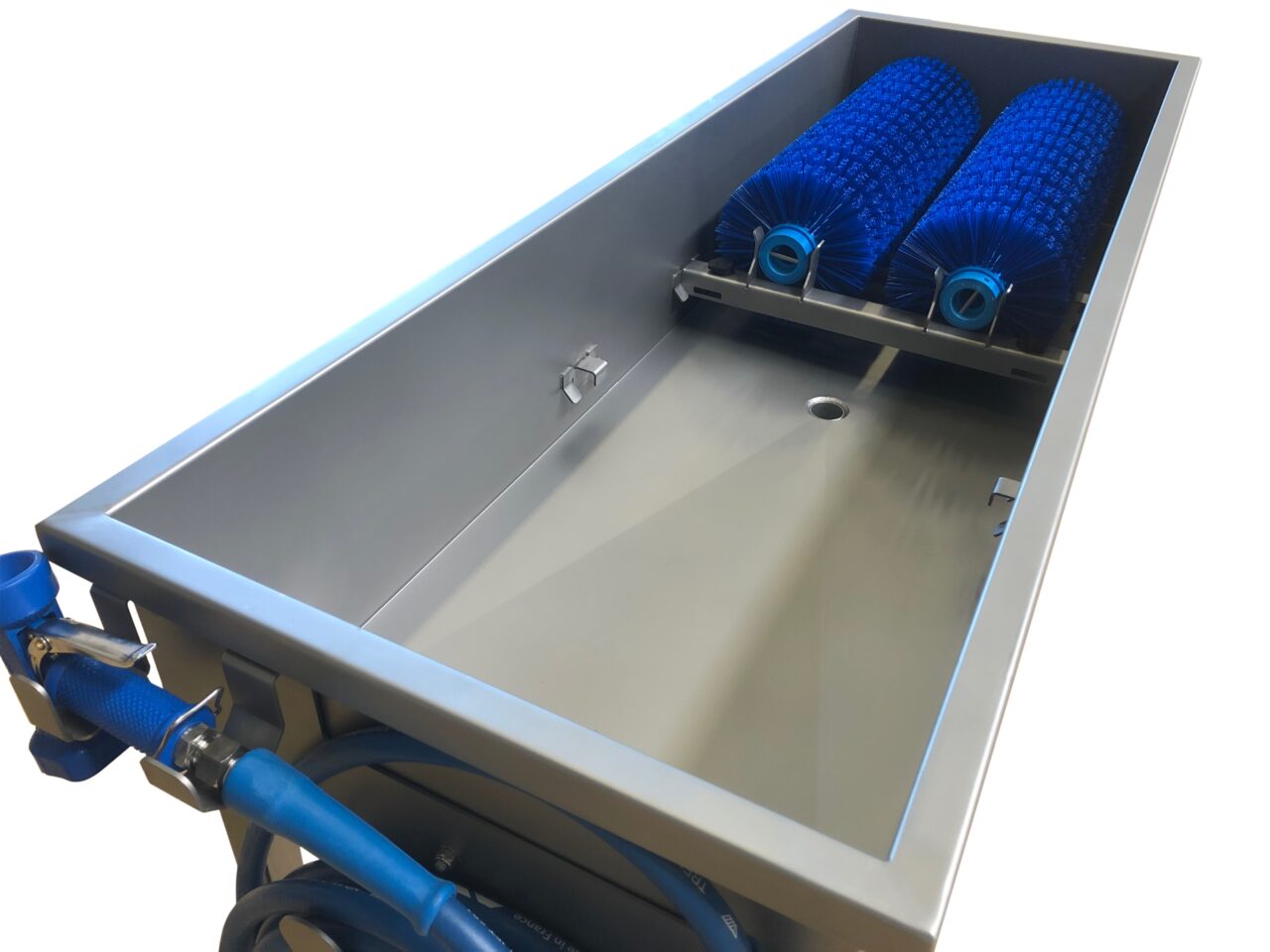

The brush cleaning station makes it very easy and practical to clean your brushes. Thanks to the spray gun and flexible hose you can clean every Elpress brush. The brush cleaning station can also be used as a soaking bath to remove dirt. The ball valve makes sure that the water will be drained out of the station. The brush cleaning station is suitable for brushes with a maximum length of 1500 mm.

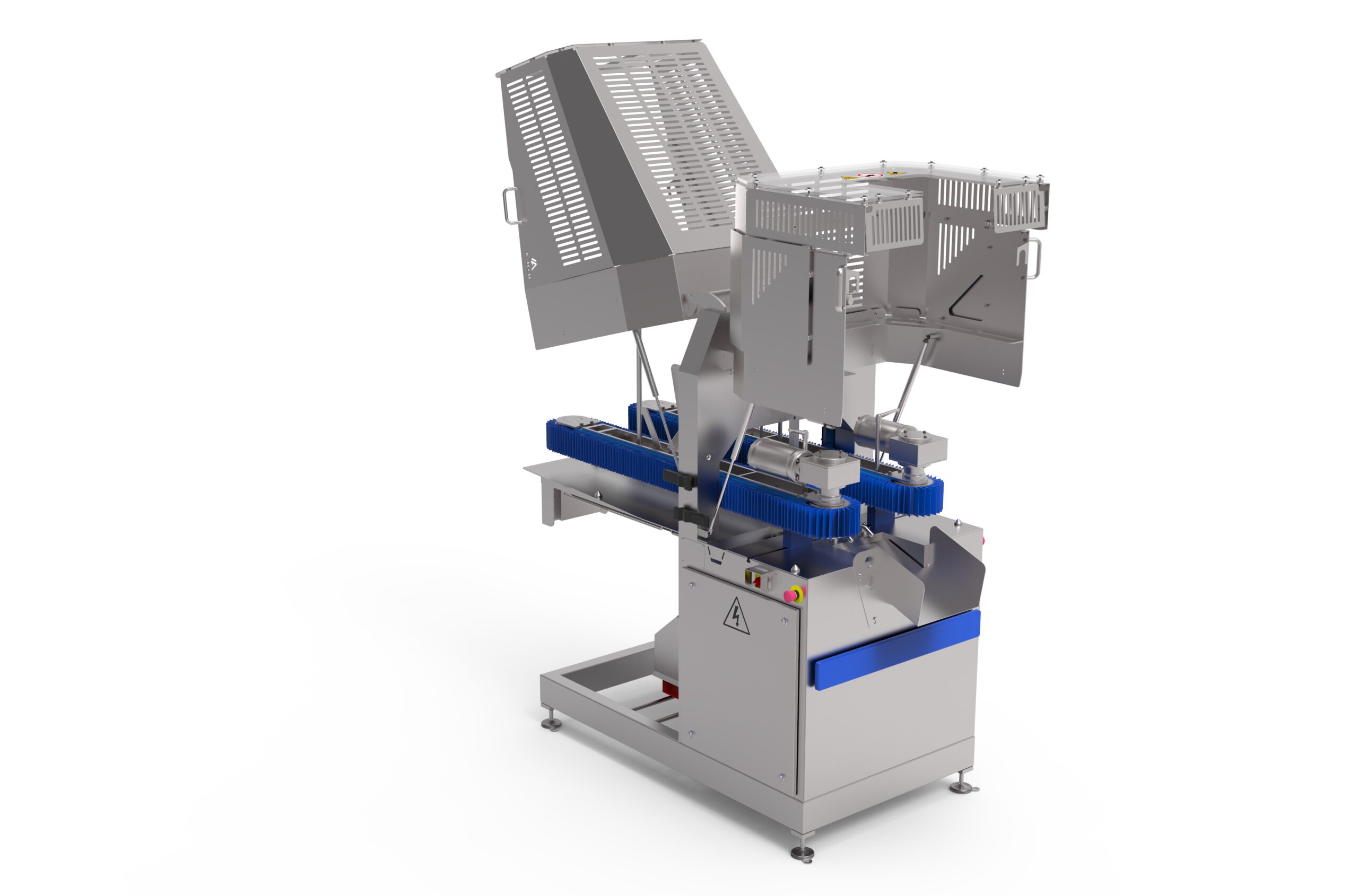

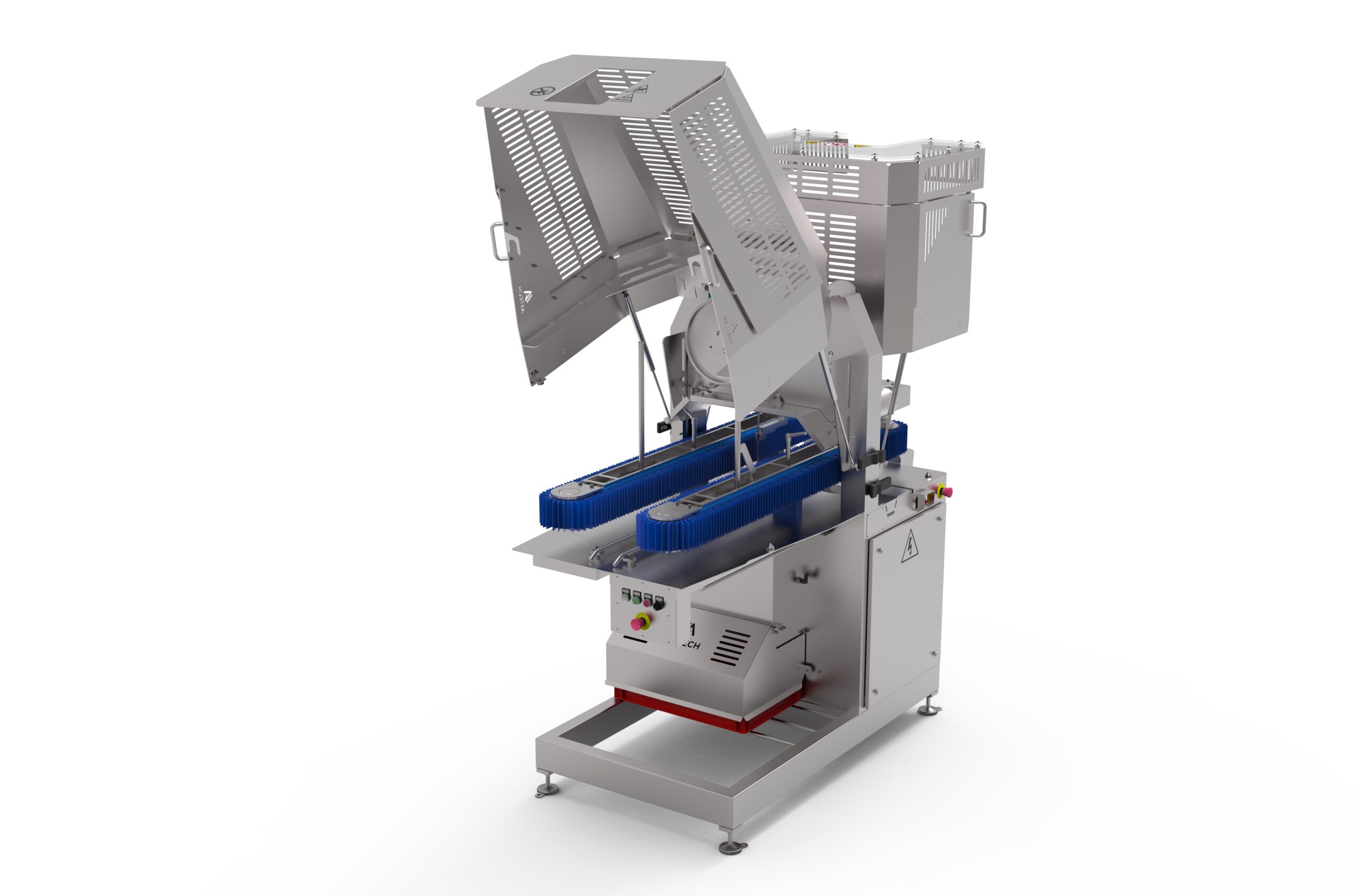

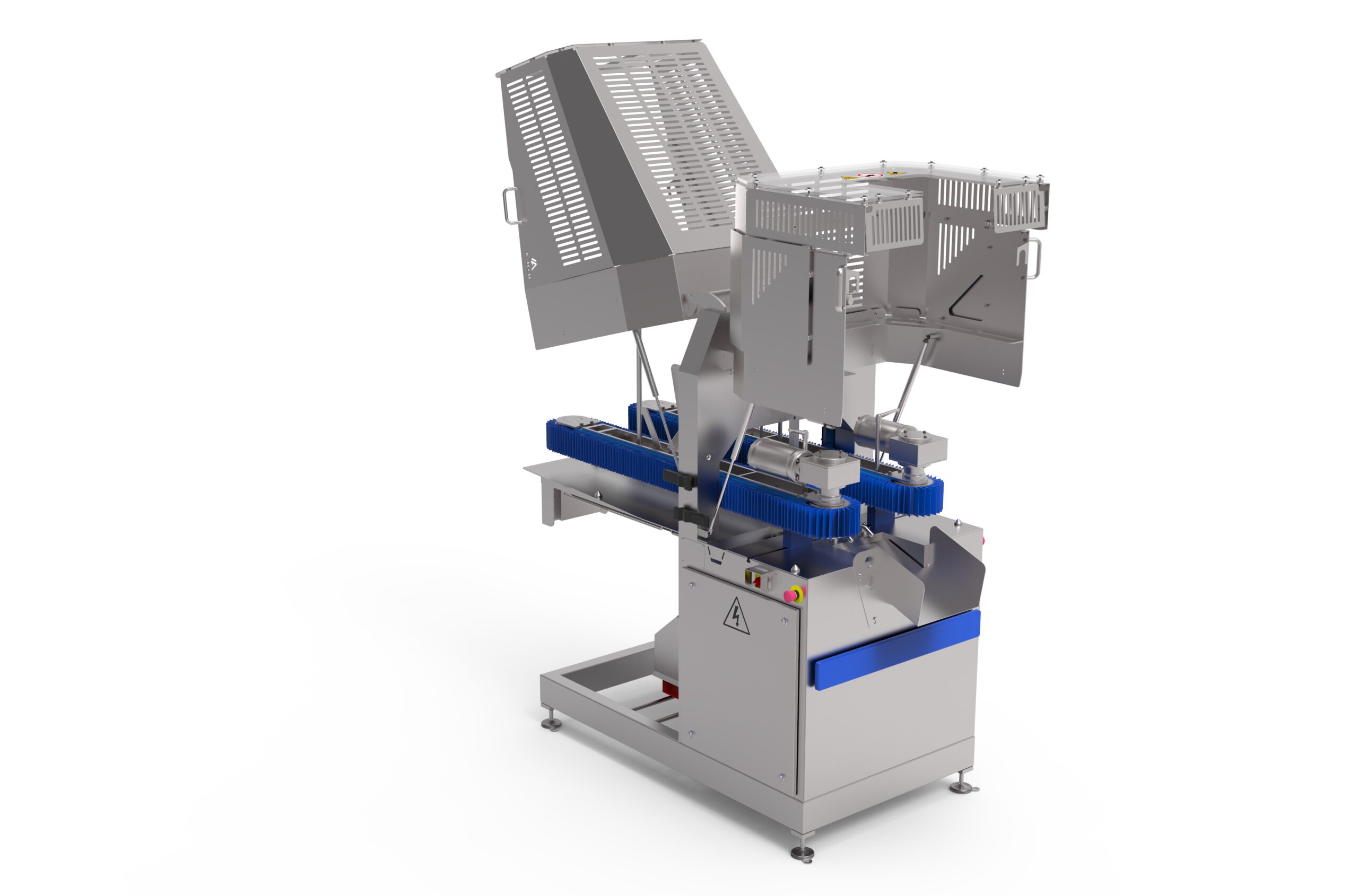

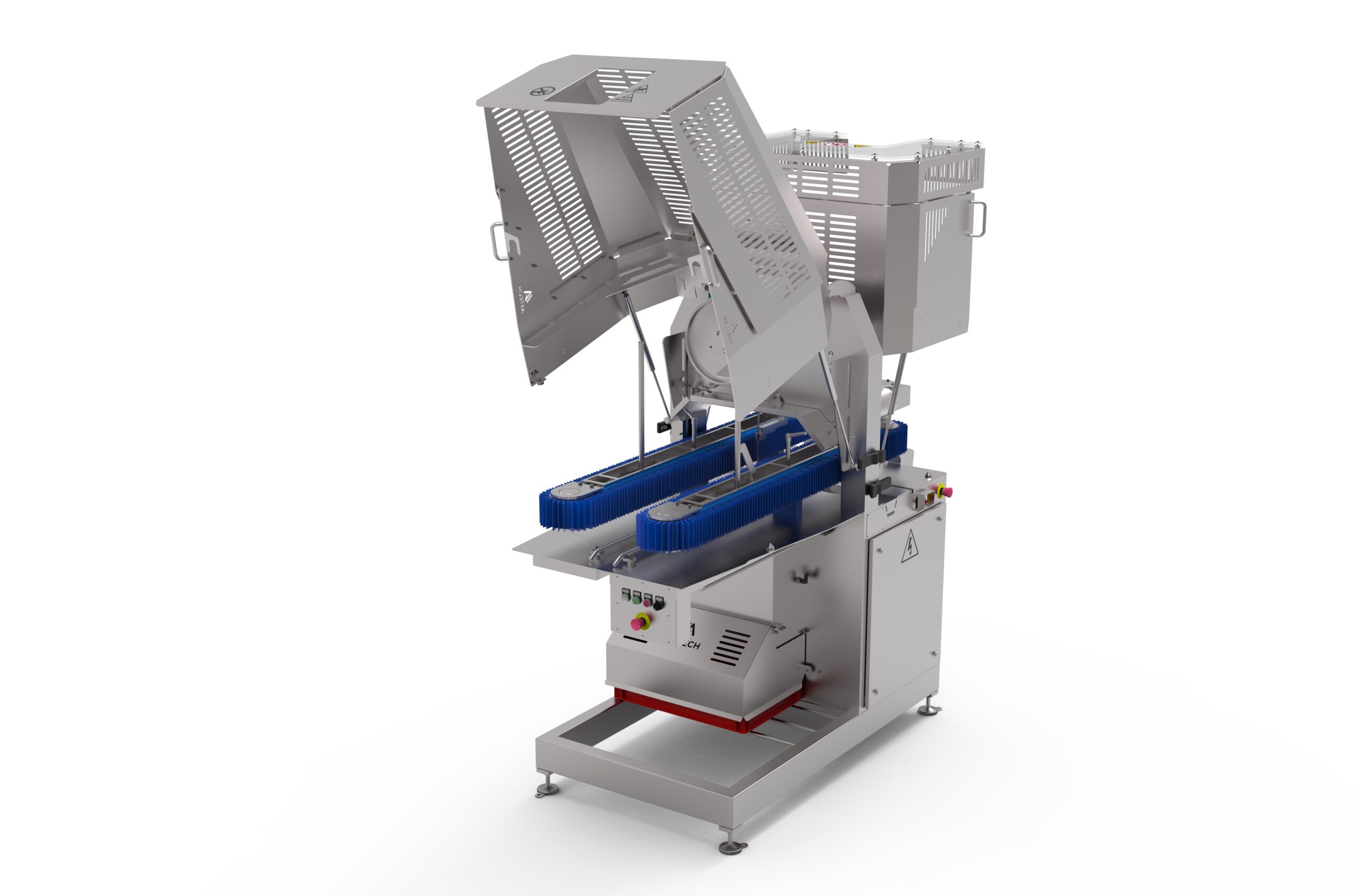

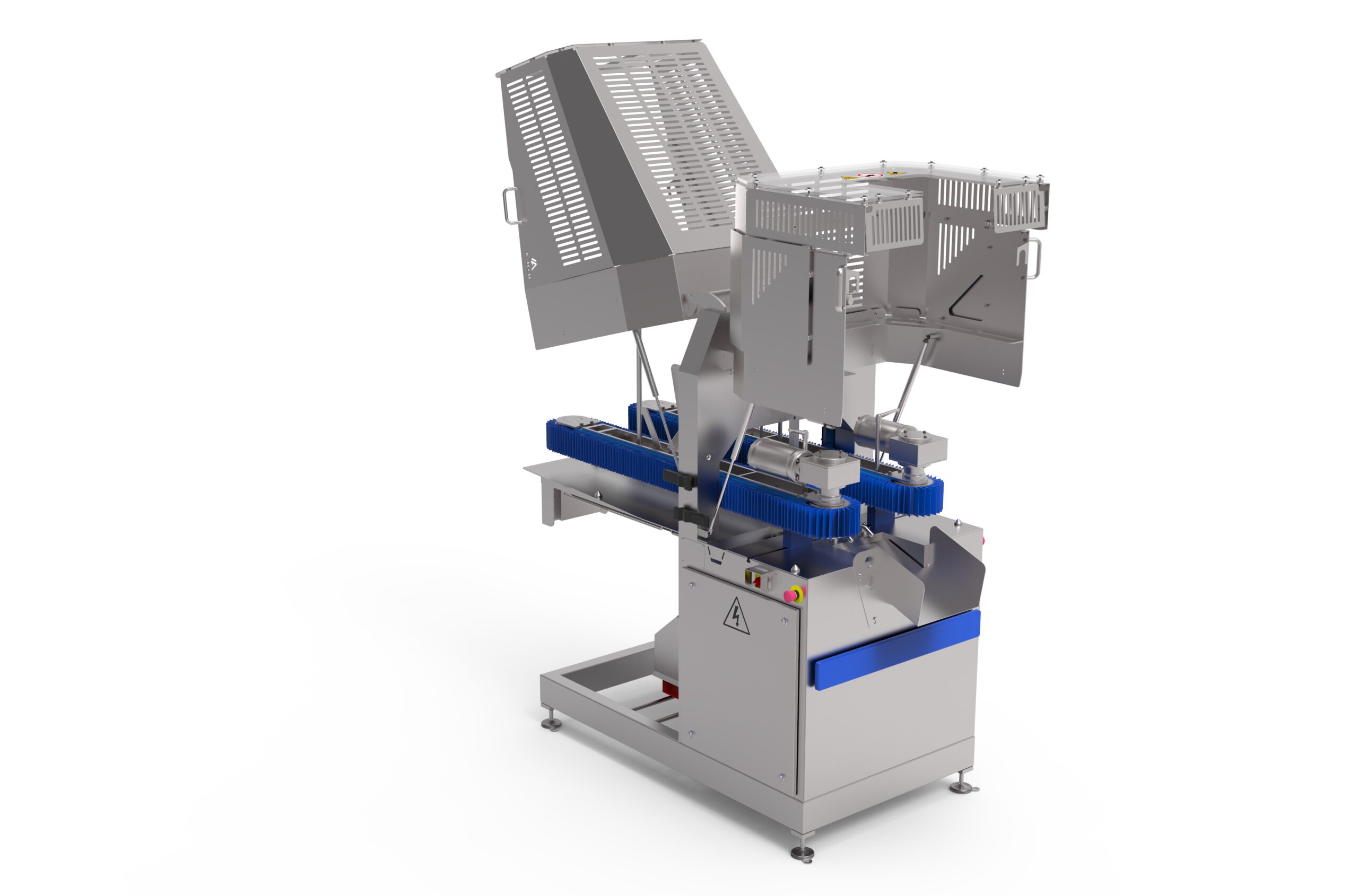

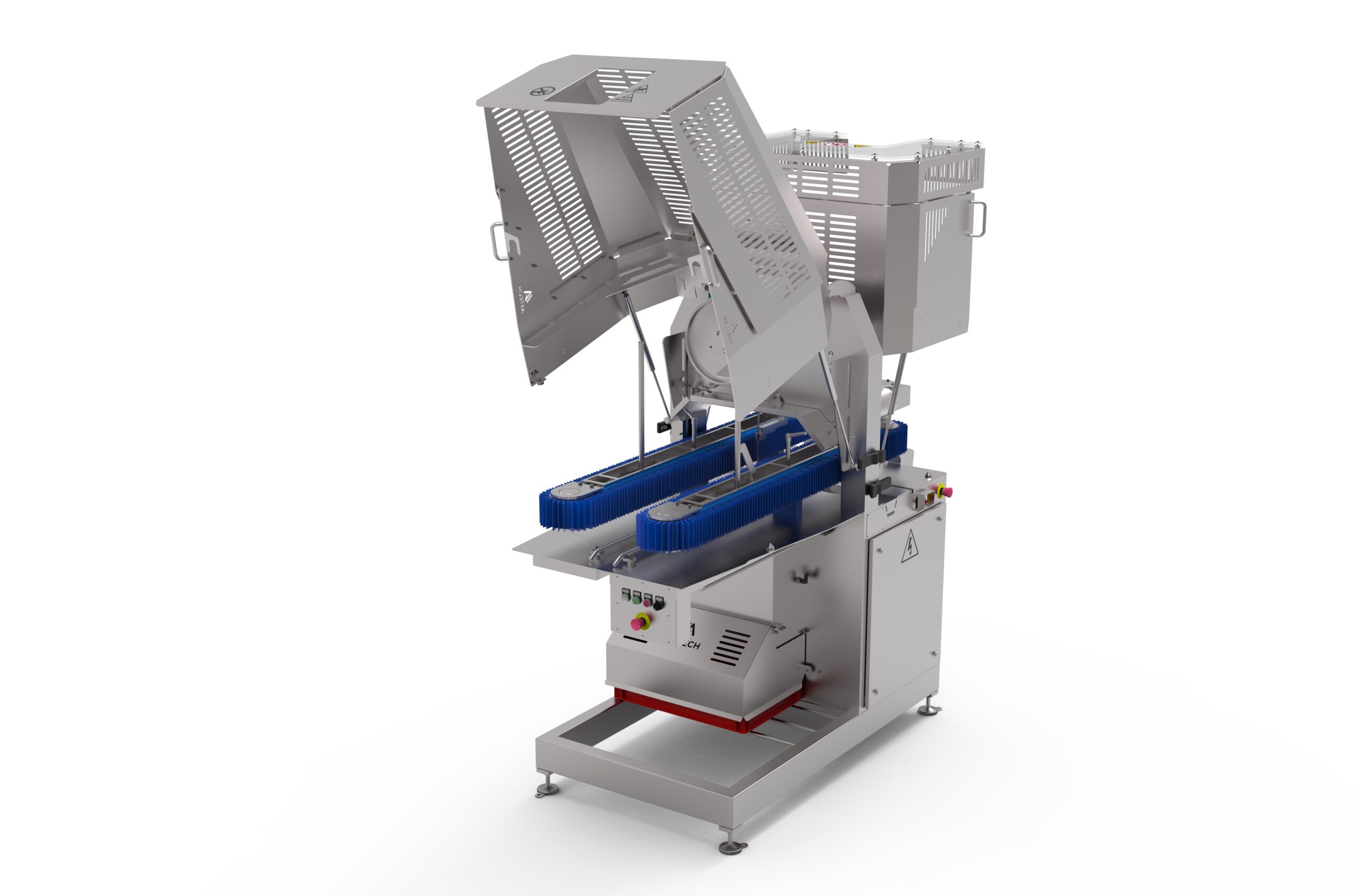

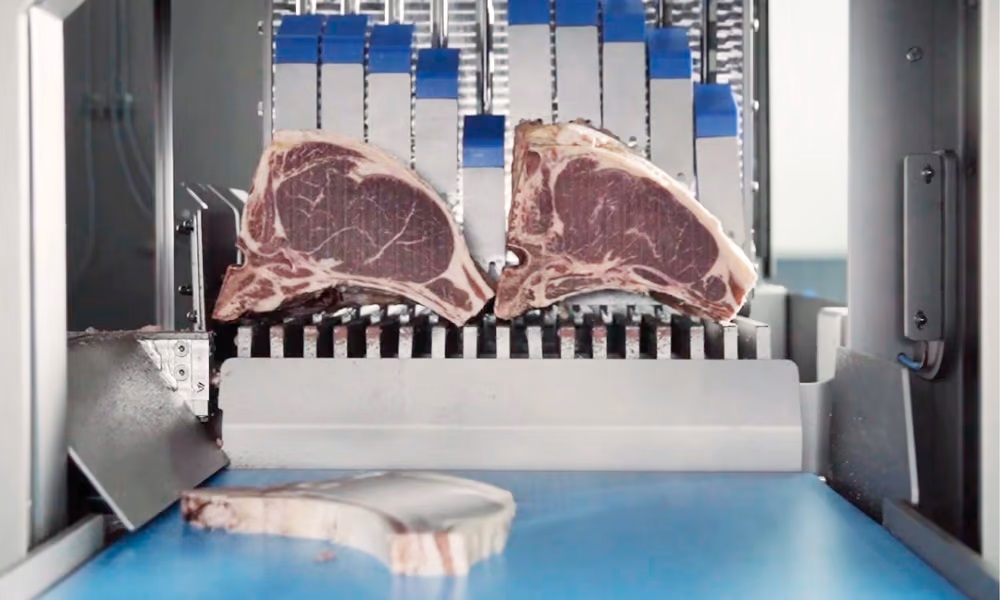

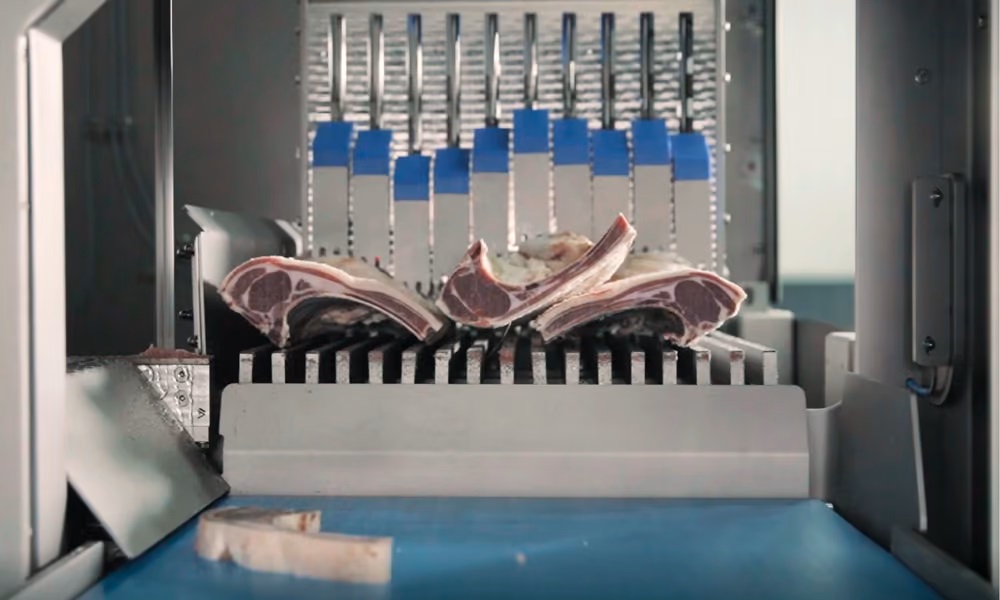

For the longitudinal cutting of products, Astech has designed the Continuous Cutter CC2. The machine makes a longitudinal cut (centered or uncentered) along a chosen product such as pig’s feet, beef legs, knuckles, blocks, etc. The CC-2 cutting machine is loaded manually and the continuous cutting is carried out using a bandsaw in a completely safe process.

The Elpress revolving gate with turnstile (EPDK) is made of stainless steel and has an ergonomic and modern design. The EPDK is motorized, demanding minimal contact from the user while passing.

For the longitudinal cutting of products, Astech has designed the Continuous Cutter CC2. The machine makes a longitudinal cut (centered or uncentered) along a chosen product such as pig’s feet, beef legs, knuckles, blocks, etc. The CC-2 cutting machine is loaded manually and the continuous cutting is carried out using a bandsaw in a completely safe process.

A forced hygiene process reduces the risk of contamination. An Elpress turnstile makes it possible to use a forced hygiene process before entering production areas. This model is available as a wall-mounted model and as a standing model. Both models are available as left-hand and right-hand versions.

Η Astech έχει σχεδιάσει μία πριονοκορδέλα για την αυτόματη κοπή κατεψυγμένου προϊόντος με οστό ή χωρίς οστό, με πολύ μικρές διαστάσεις και με πλήρως κλειστό σχεδιασμό που το καθιστά πολύ ασφαλές για την εργασία.

For the longitudinal cutting of products, Astech has designed the Continuous Cutter CC2. The machine makes a longitudinal cut (centered or uncentered) along a chosen product such as pig’s feet, beef legs, knuckles, blocks, etc. The CC-2 cutting machine is loaded manually and the continuous cutting is carried out using a bandsaw in a completely safe process.