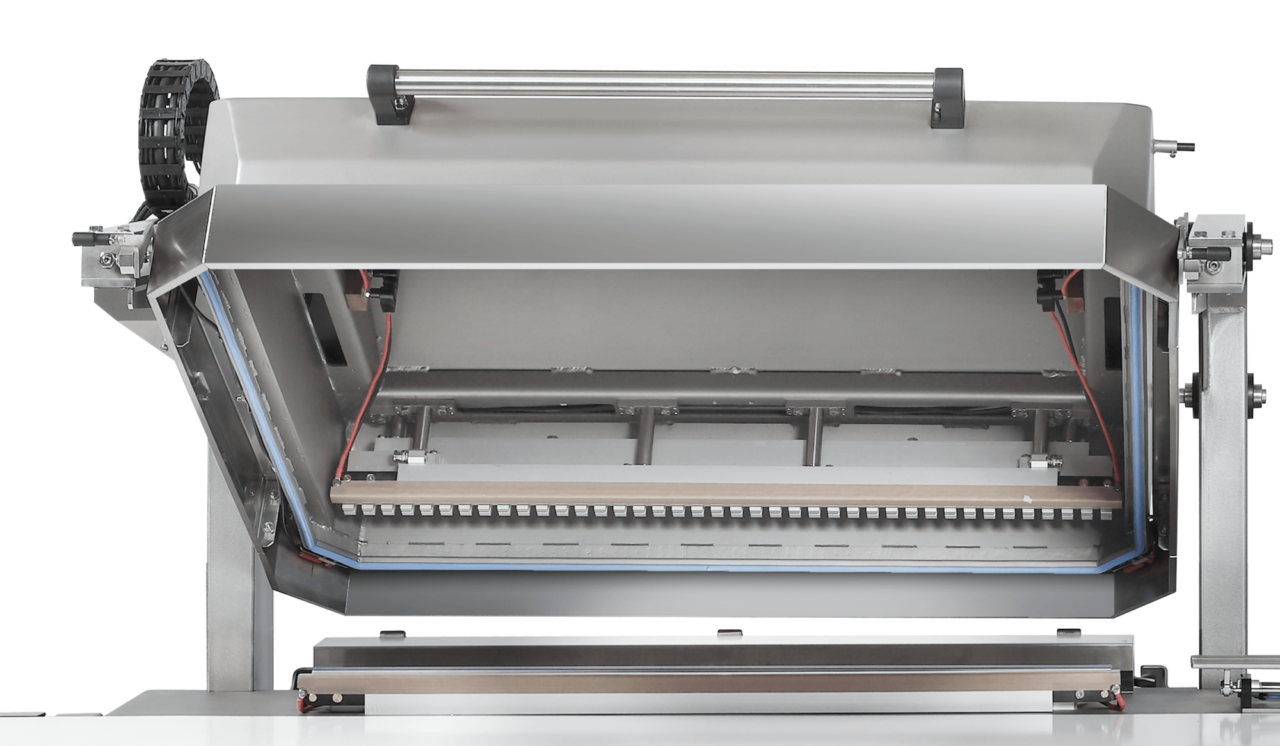

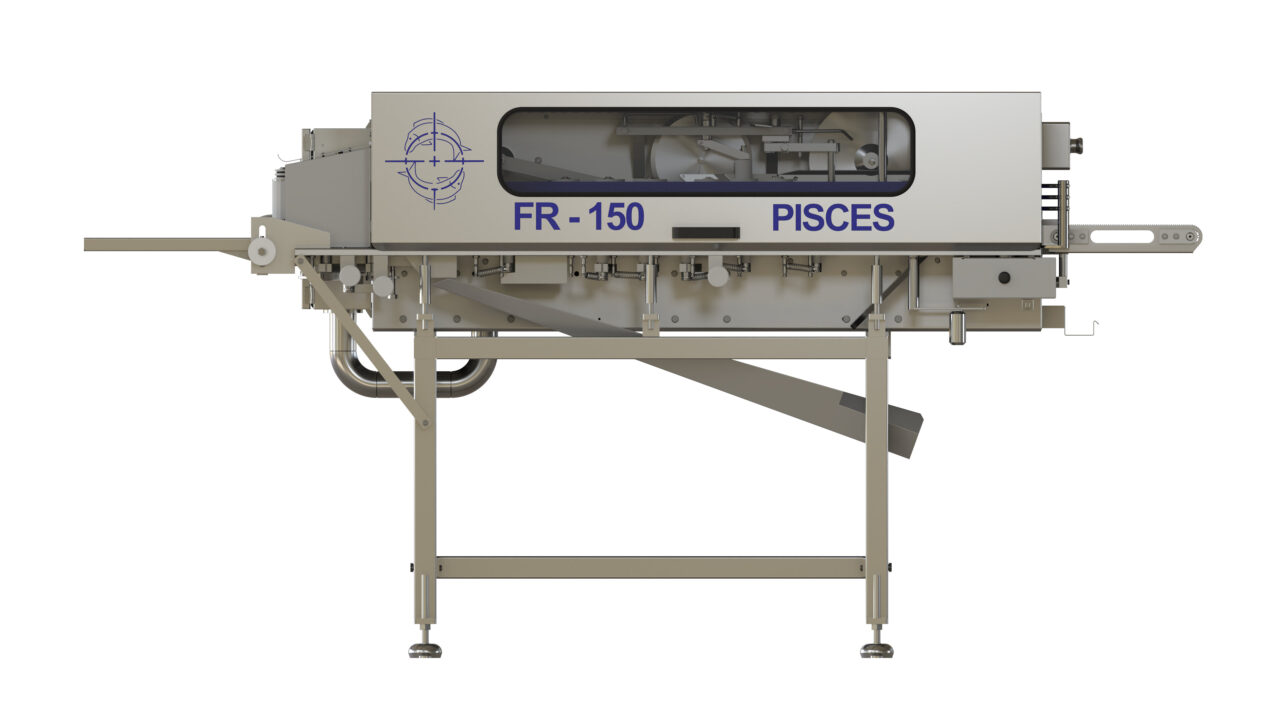

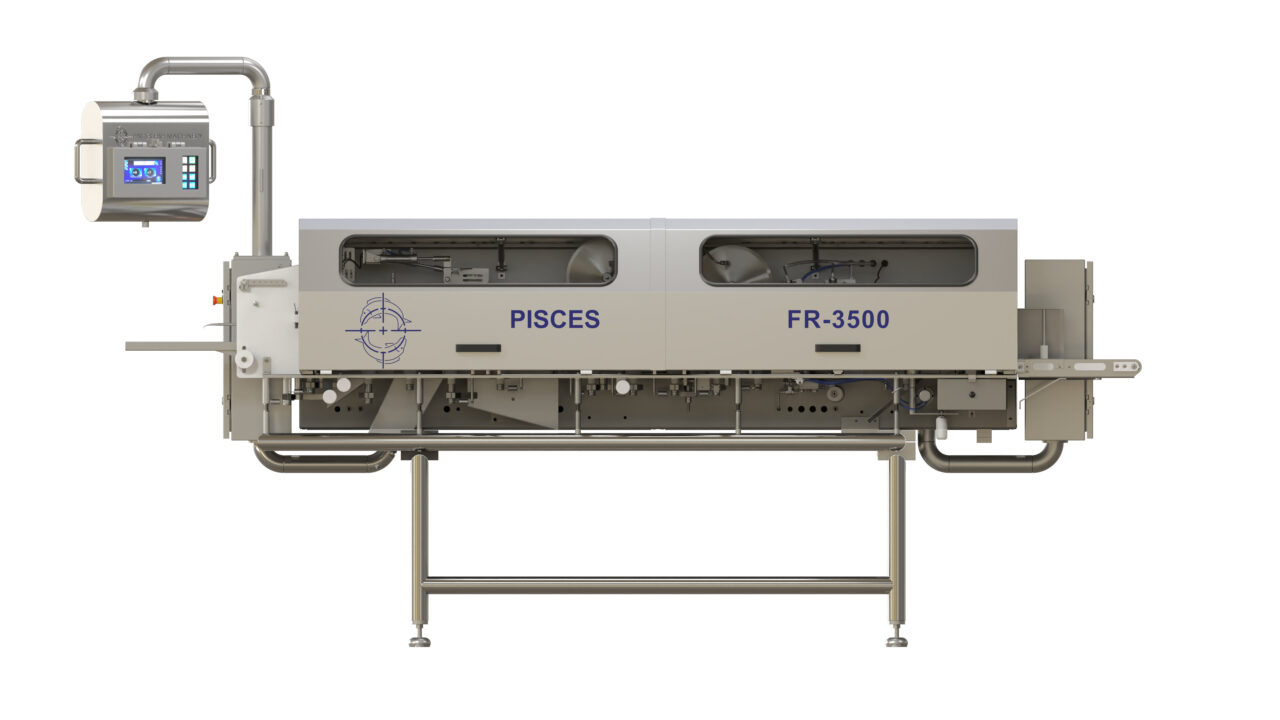

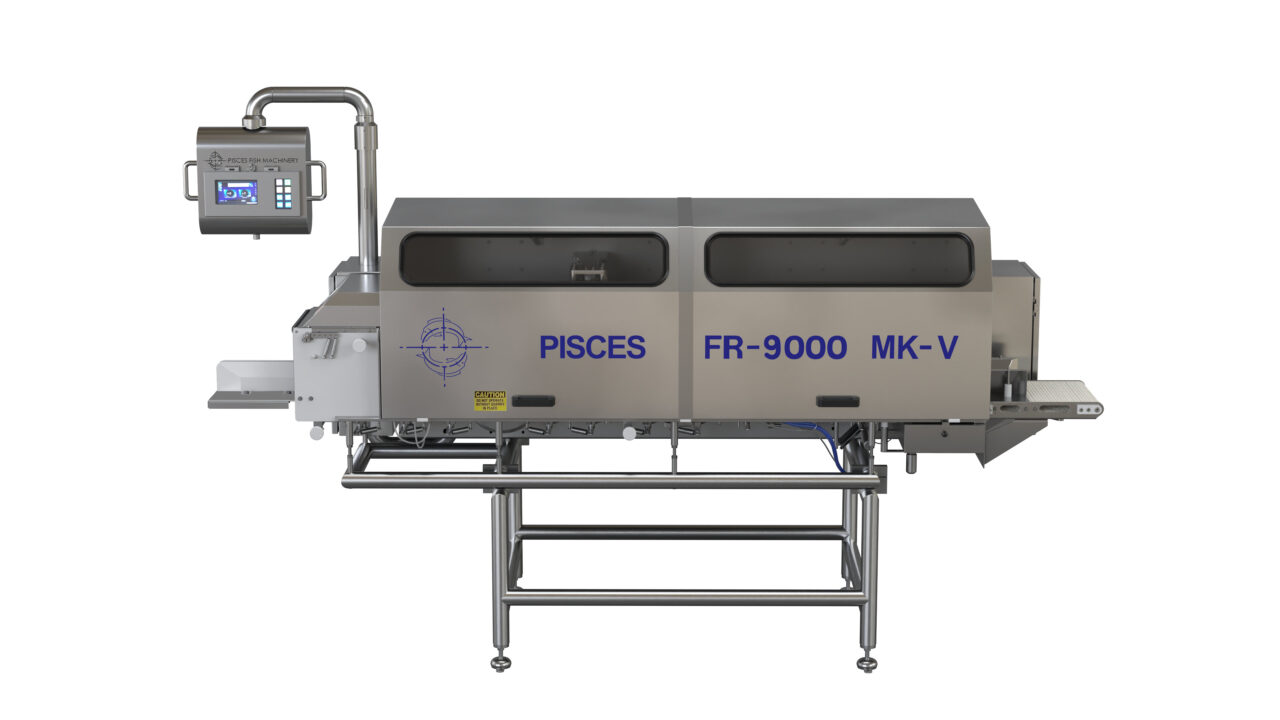

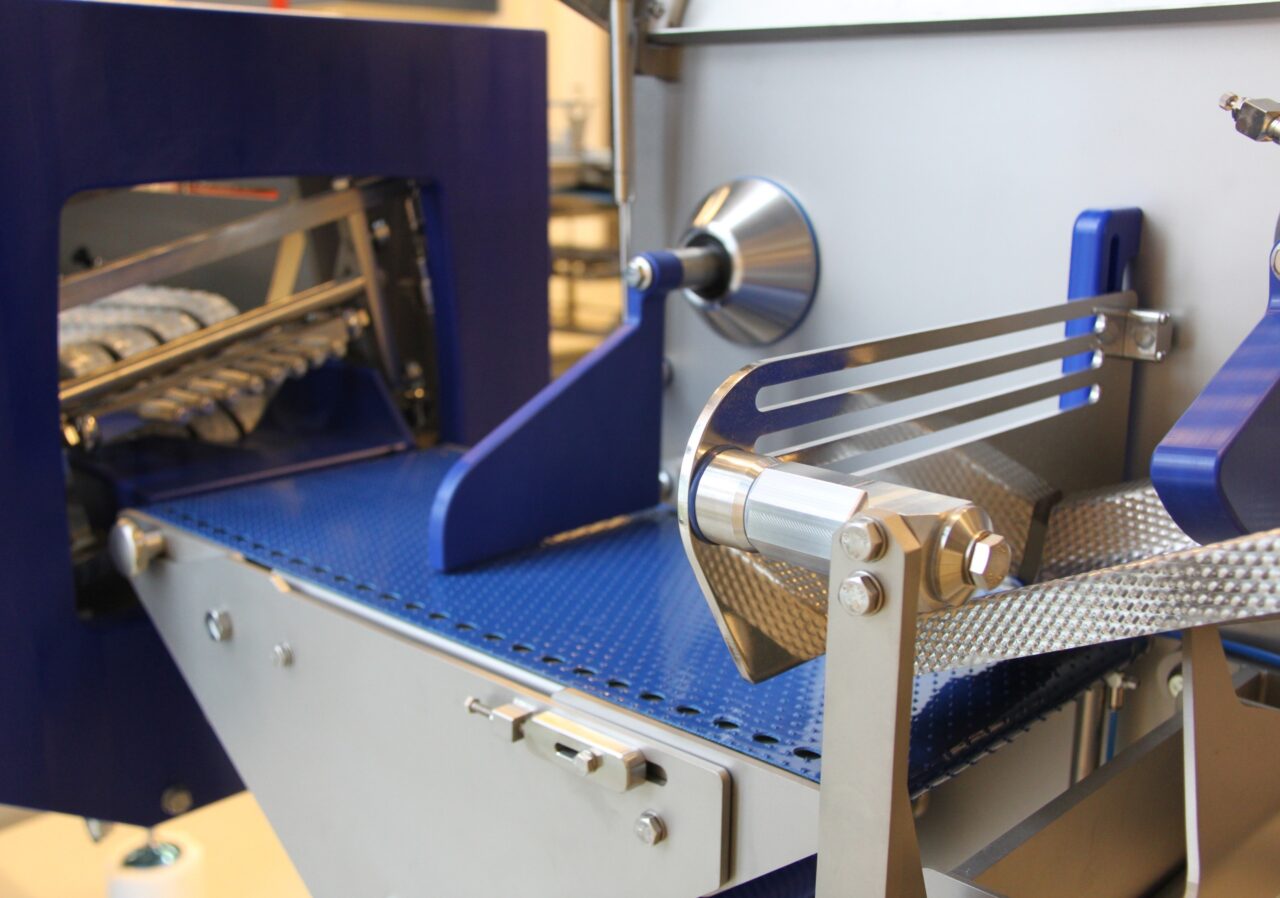

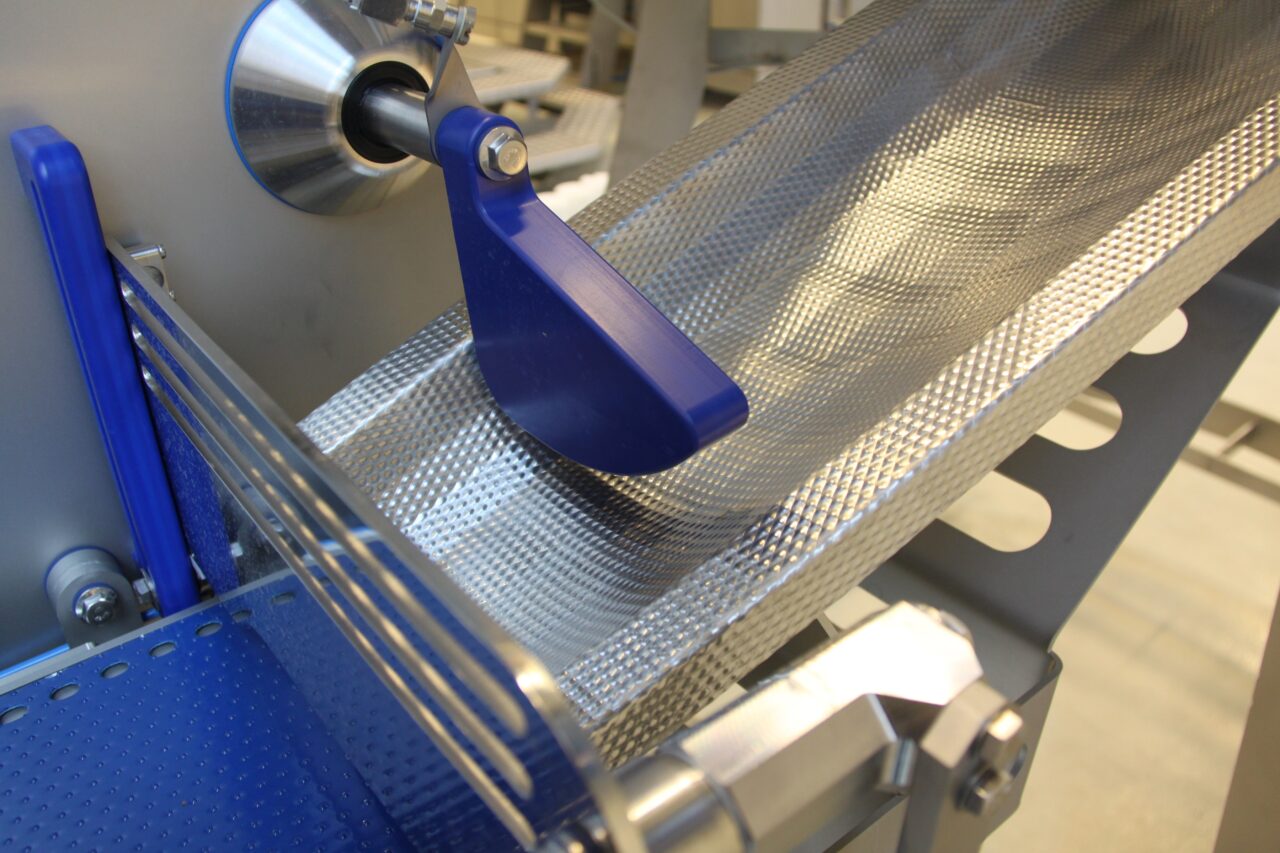

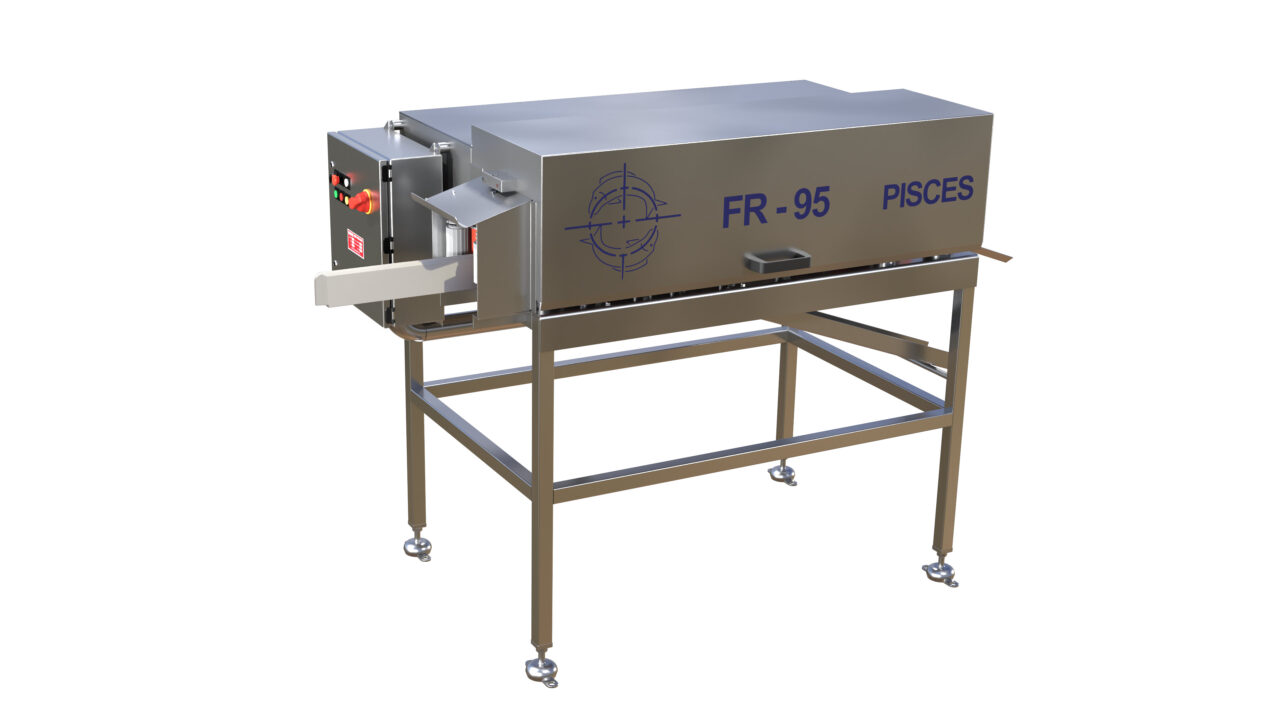

The FR filleting machines are reliable, versatile and high speed, specially designed for the production of single fillets free of backbone and ribs.

FR-65 FR-95 70 – 400 g 1000 – 4000 g 50 fish/minute 40 fish/minute 40 mm 75 mm 1800x915x1245 mm 1800x860x1320 mm 6 kW ½ 12 l/min 1

FR-65 70 – 400 g 50 fish/minute 40 mm 1800x915x1245 mm 6 kW ½ 12 l/min 1

FR-75 300 – 2000 g 40 fish/minute 50 mm 1800x915x1245 mm 6 kW ½ 12 l/min 1

FR-95 1000 – 4000 g 40 fish/minute 75 mm 1800x860x1320 mm 6 kW ½ 12 l/min 1

Special Features

Technical Specifications

FR-75

Fish size

300 – 2000 g

Productivity

40 fish/minute

Maximum rib size

50 mm

Dimensions (LxWxH)

1800x915x1245 mm

Power

Water connection

Water consumption

Operators

Fish size

Productivity

Maximum rib size

Dimensions (LxWxH)

Power

Water connection

Water consumption

Operators

Fish size

Productivity

Maximum rib size

Dimensions (LxWxH)

Power

Water connection

Water consumption

Operators

Fish size

Productivity

Maximum rib size

Dimensions (LxWxH)

Power

Water connection

Water consumption

Operators

Additional information