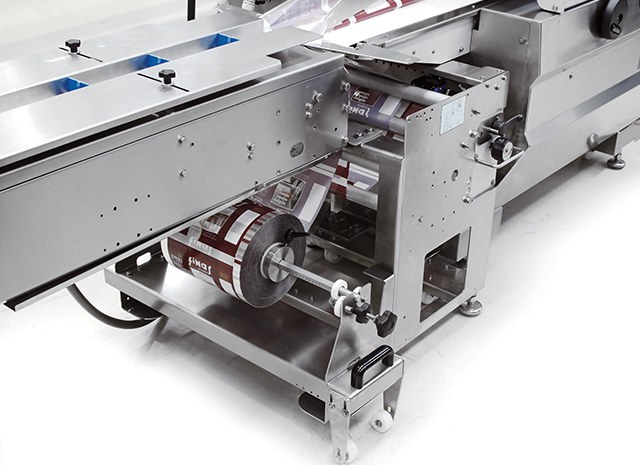

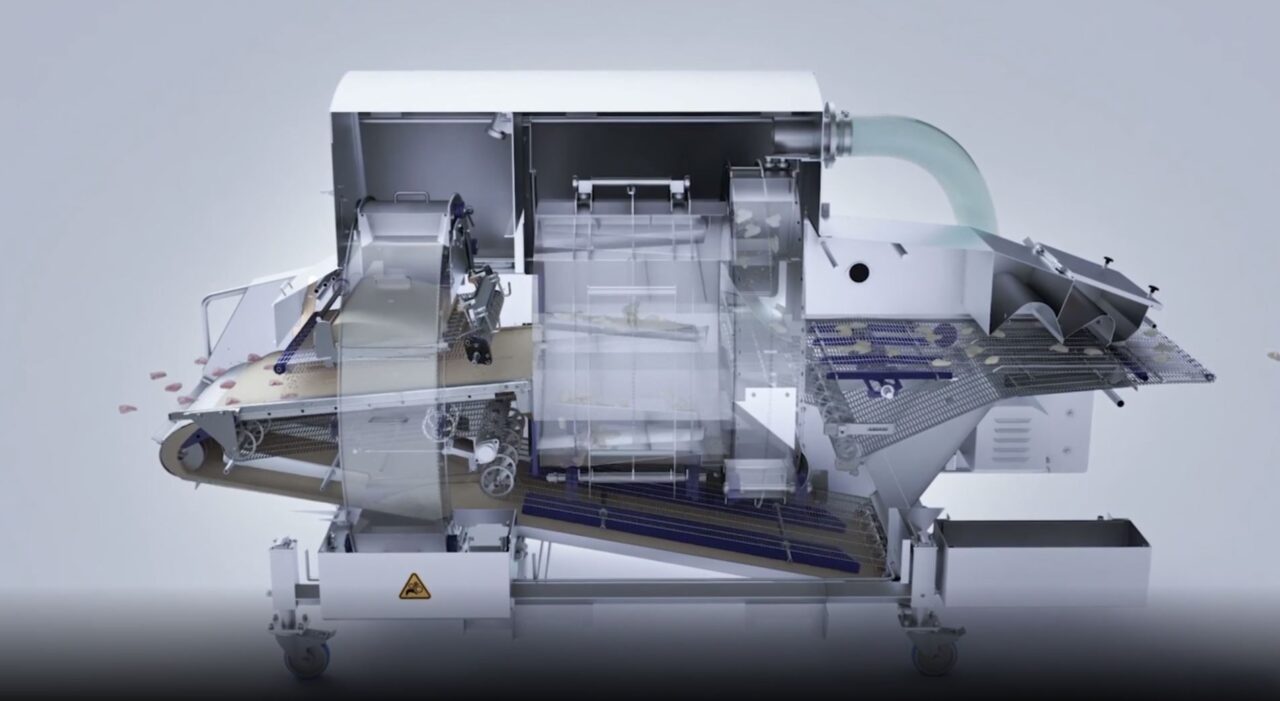

Horizontal Flow Wrapper (HFFS) that makes a three sealing pillow pack. Specially oriented to bakery, cookies, chocolates and candy-confectionery industries.

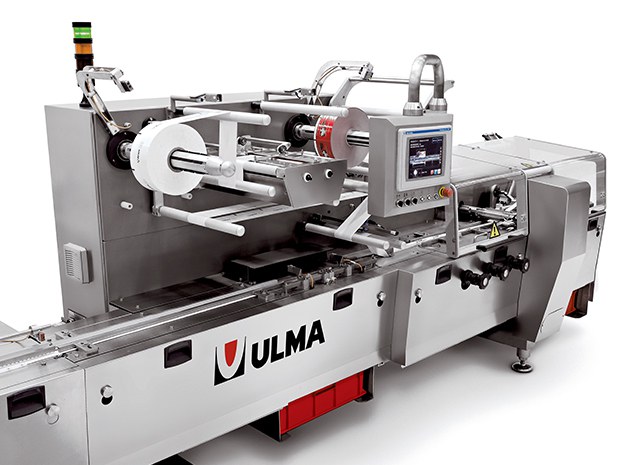

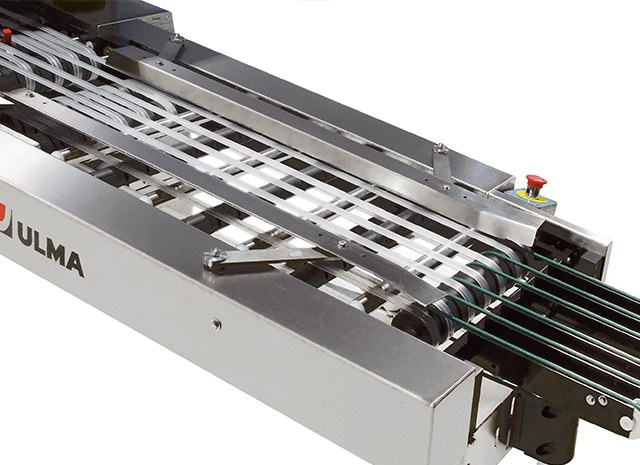

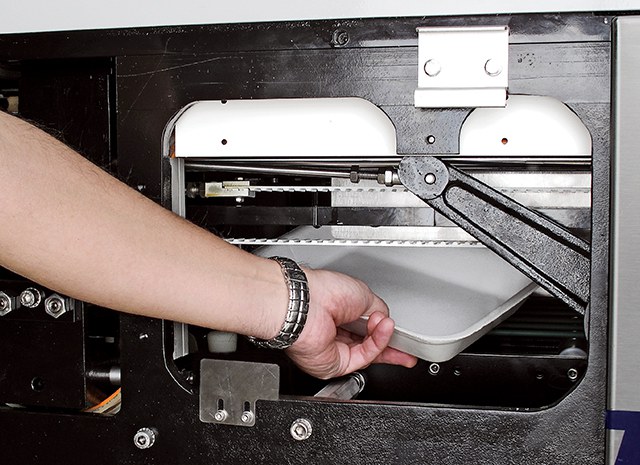

The new FR 305 features all these characteristic strength, reliability, and operation simplicity of the ULMA machines, together with an ergonomic cantilever design that makes cleaning and sanitizing easier. Added to these well known characteristics of ULMA machines, the new model also features very high flexibility for the different format changeovers thanks to the state of the art industrial PC electronic platform.

All these features make the FR 305 the ideal machine that will fulfil the needs of customers requiring to pack irregular products or products that are difficult to transport.

Special features

- Electronic packaging machine powered with independent motors synchronized electronically

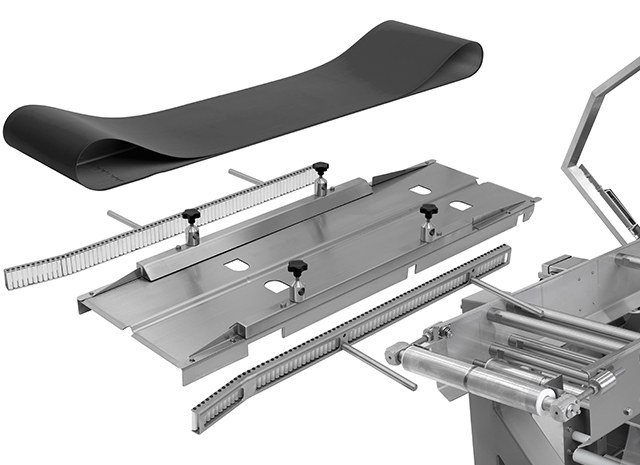

- Machine is built on a cantilever format

- Left to Right operating direction

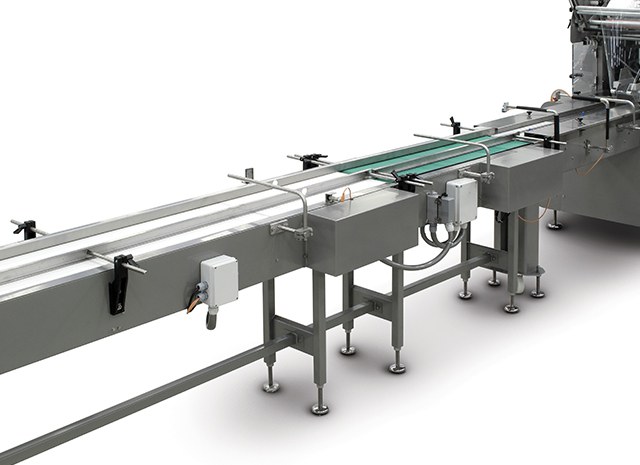

- In-feed conveyor is 2 meters long (in the standard configuration)

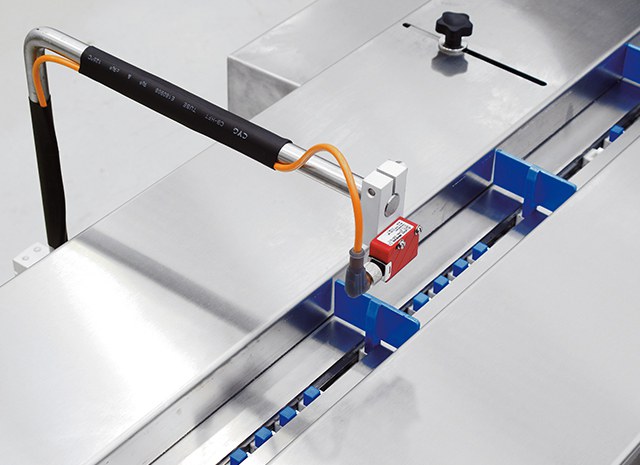

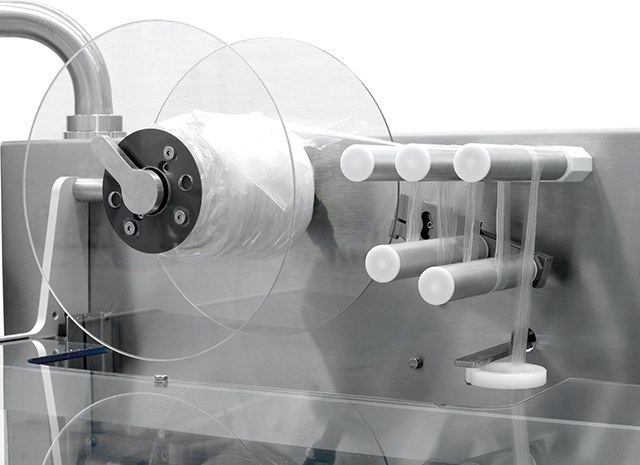

- Longitudinal sealing system by film feeding and sealing rollers, with a height adjustment system providing quick and easy settings

- Cross seal is made by rotary sealing jaws with an electronic overload safety switch

- Machine parameter settings (bag length, pusher position, …) from touch screen

- Machine includes a 5″ monochrome touch screen

Additional information