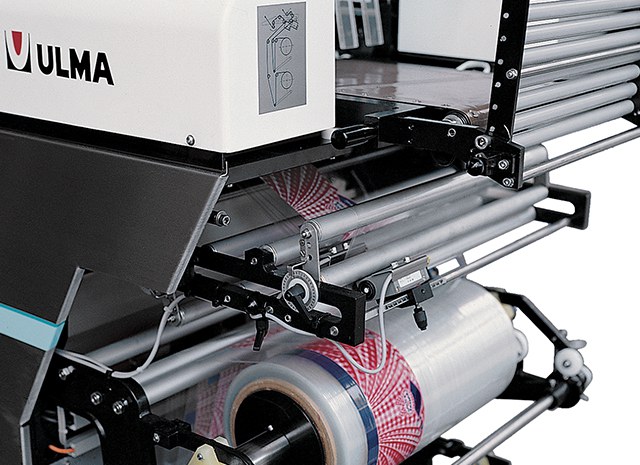

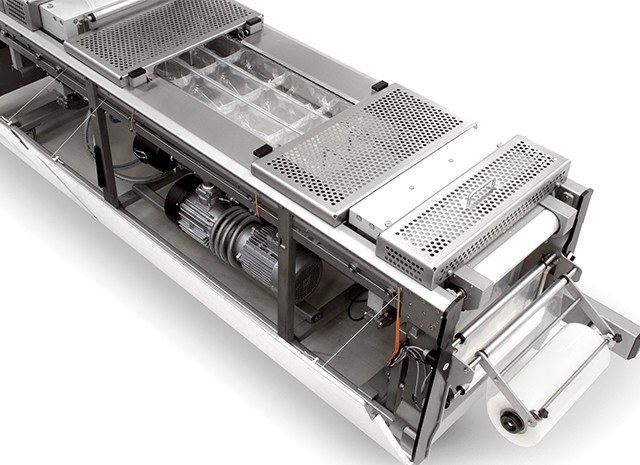

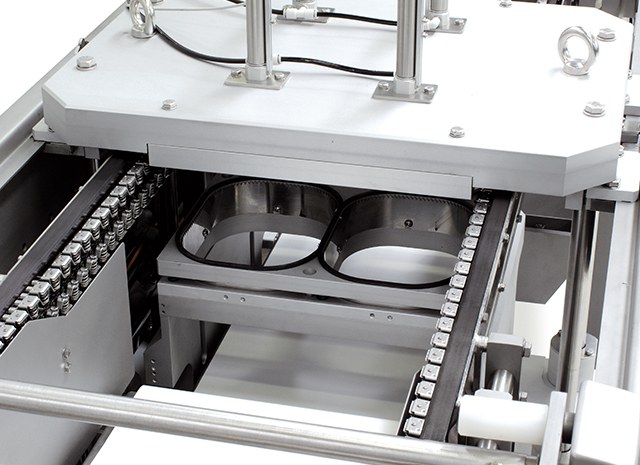

Horizontal Flow Wrapper (HFFS) that makes a shrink film pack for frozen fish.

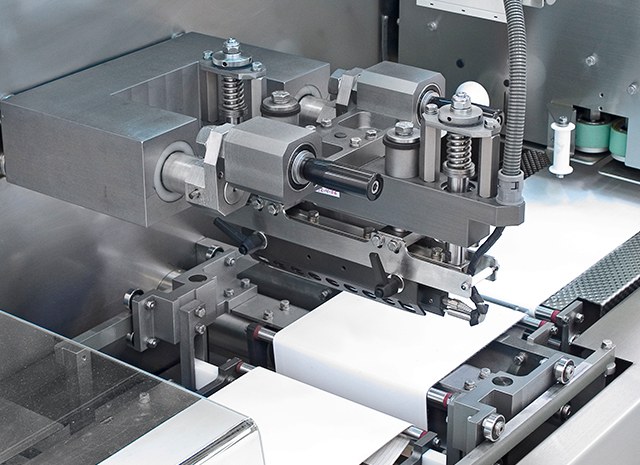

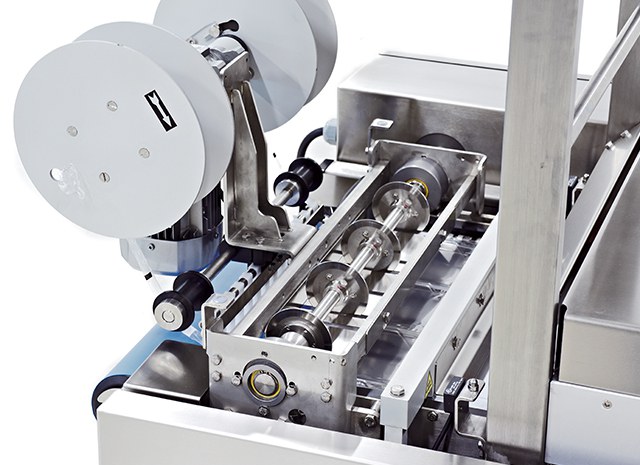

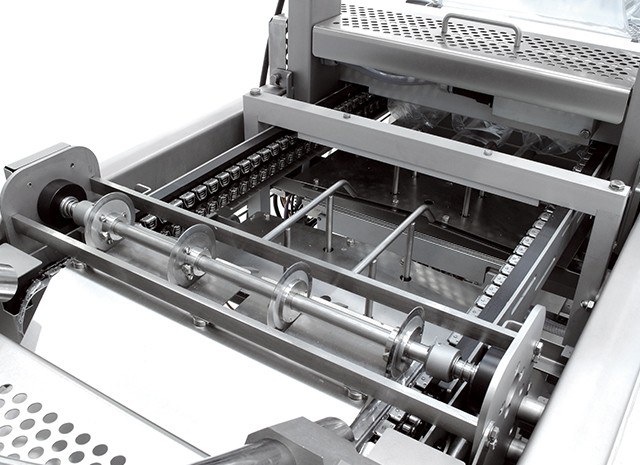

This machine has an innovative design cross sealing station. The sealing jaw describes an oval movement, which allows to reach high sealing speeds and simplifies the transfer of the product through the sealing jaw. These features increase machine’ s productivity and minimize the reject levels.

Technical Specifications

- Hygienic design

- Ιnnovative design cross sealing station

- High sealing speeds

- Minimize the reject levels

- User friendly operation

Additional information