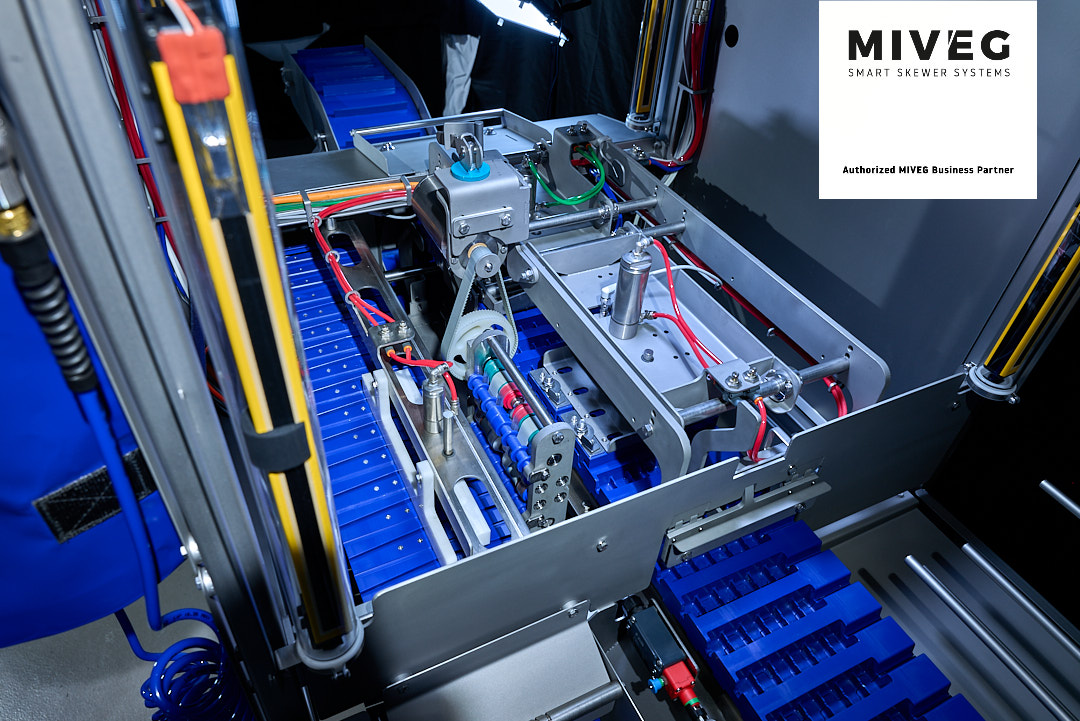

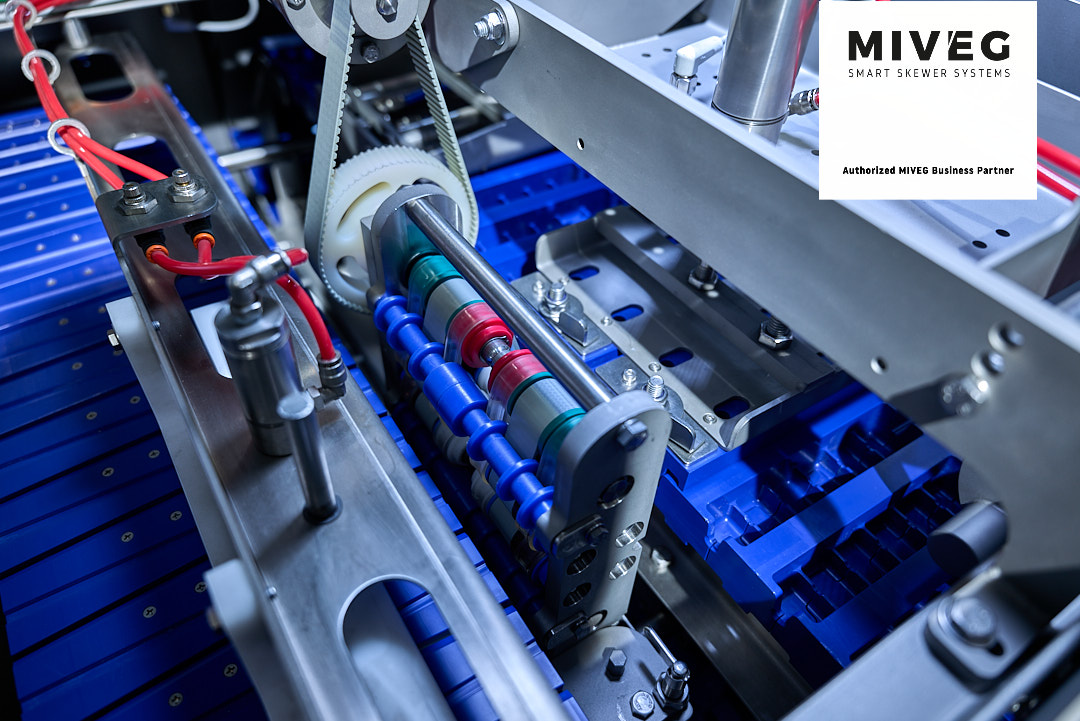

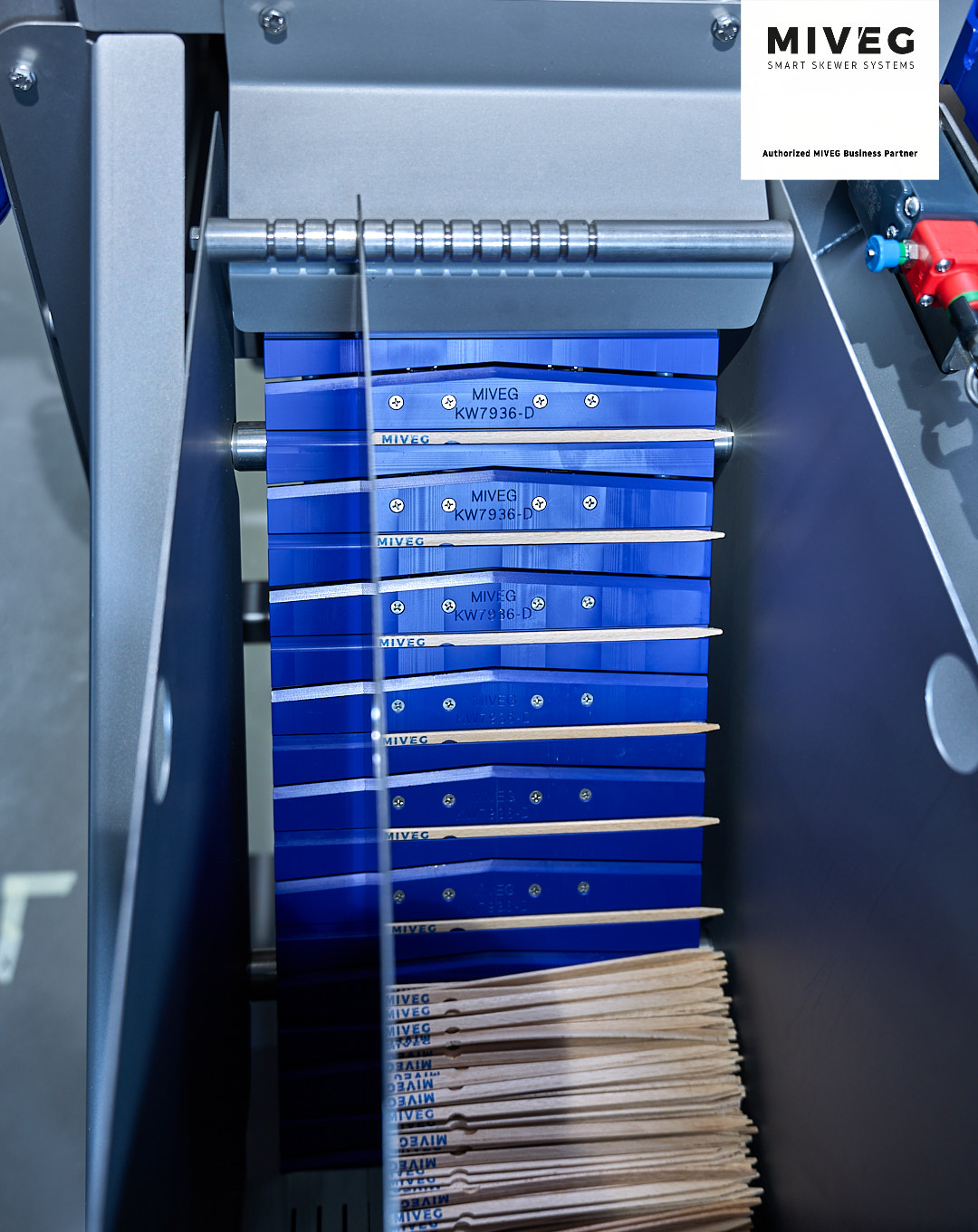

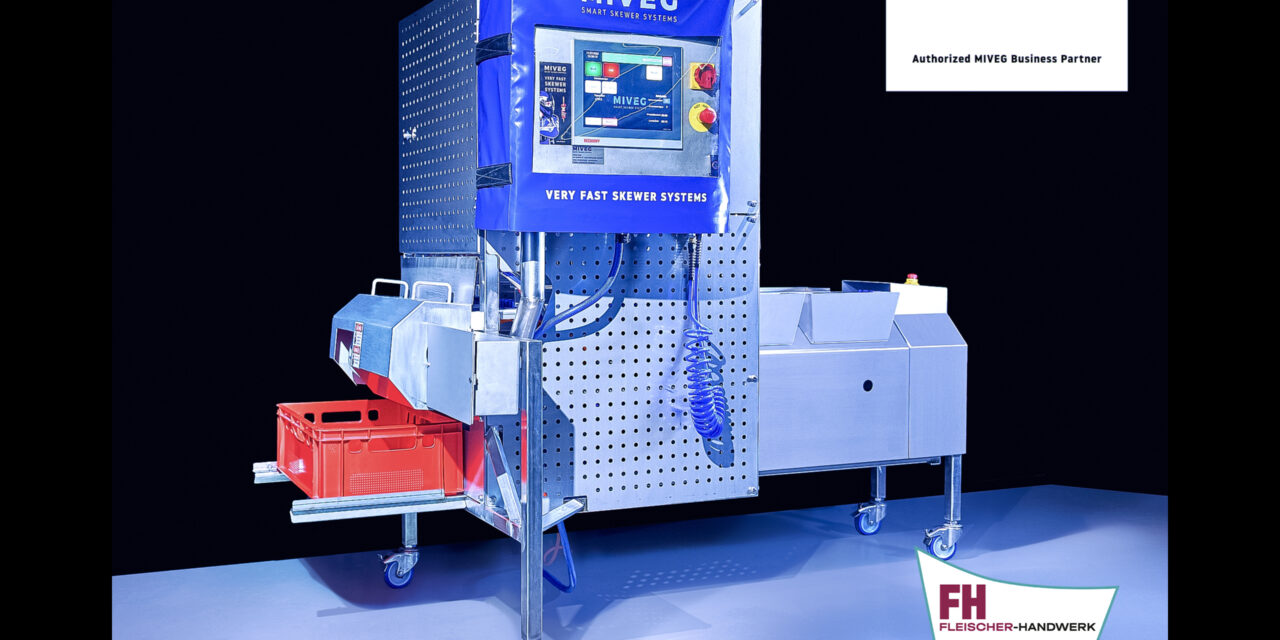

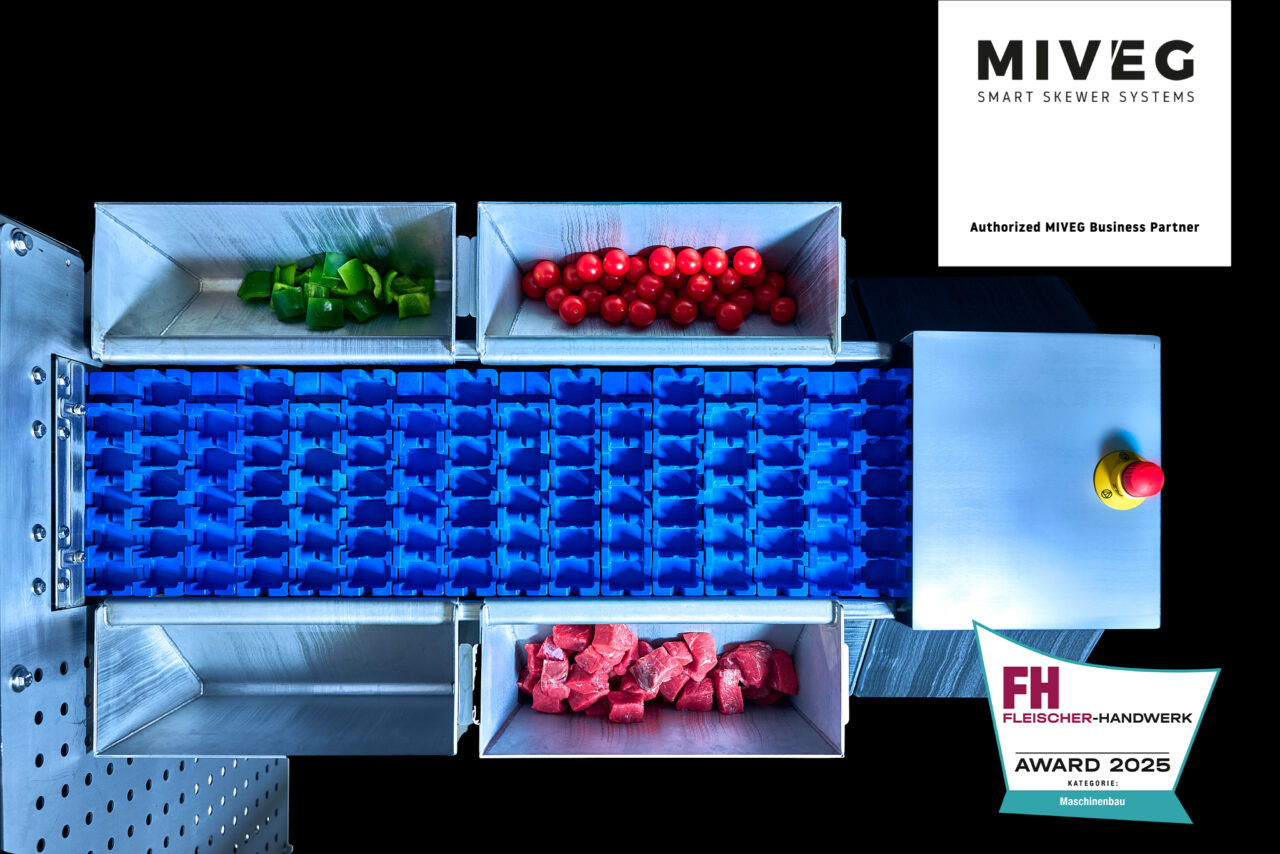

The Skewer System 2040 is the smartest and most economical way to get started with skewer automation.

up to 2040 skewers/hour 4 – 34 skewers/min 2400x1200x1800 mm 230 V 6 bar

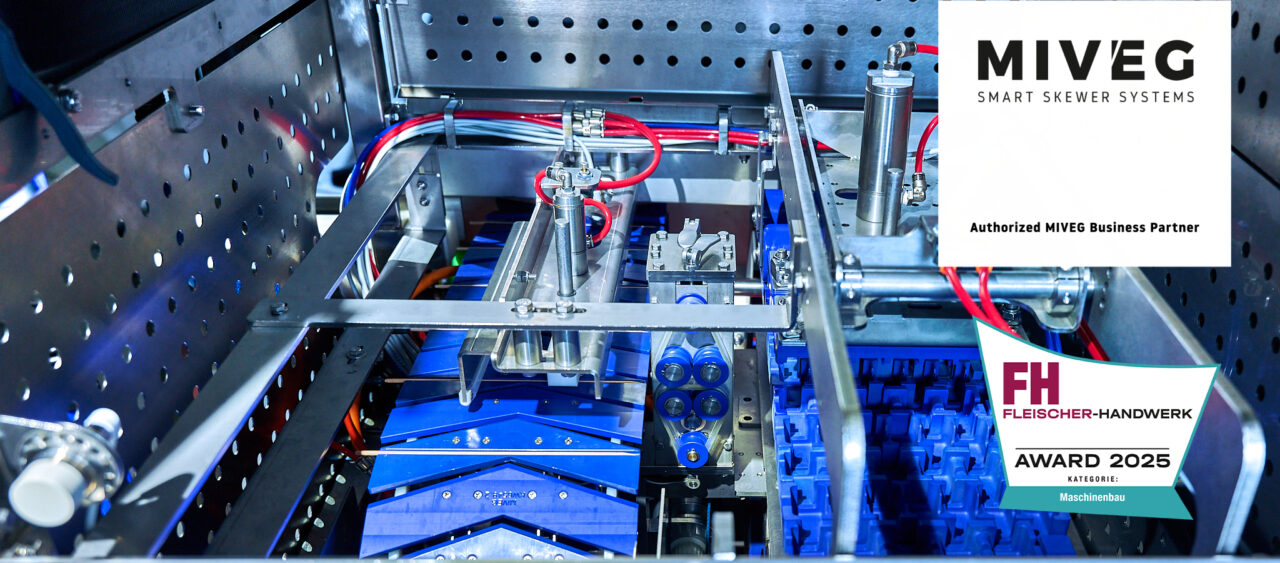

Special Features

Technical Specifications

Capacity

Dimensions (LxWxH)

Power supply

Air supply

Additional information