The Deslimer CT 1612.10 rinsing system efficiently rinses off slime, blood and bacteria from salmon, trout and other species similar in weight and texture.

CT 1612.10 CT 16.12.30 15 – 30 fish/min 40 – 60 fish/min 2,7 kW 3,3 kW 28 litres/min 48 litres/min ~500 kg ~650 kg

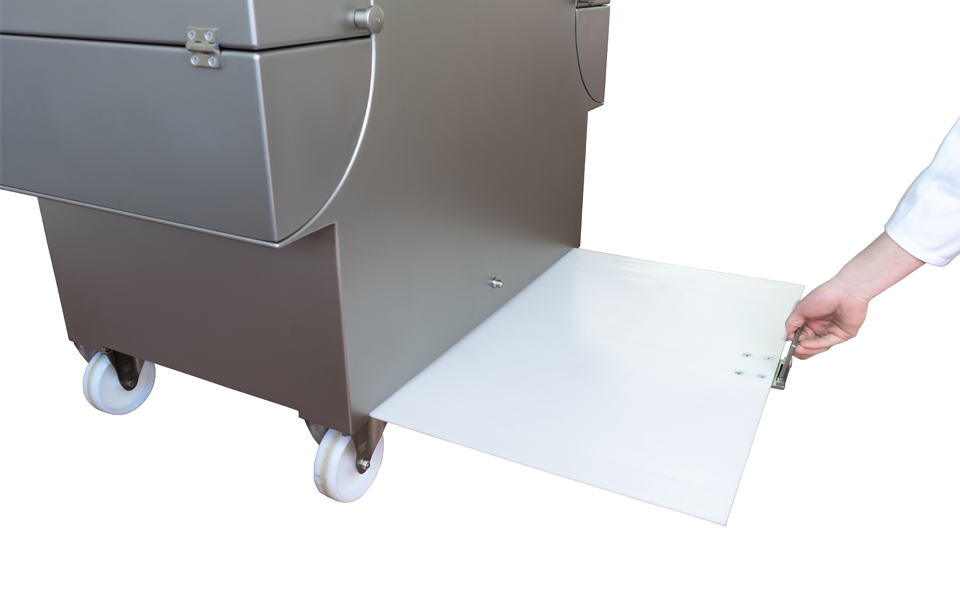

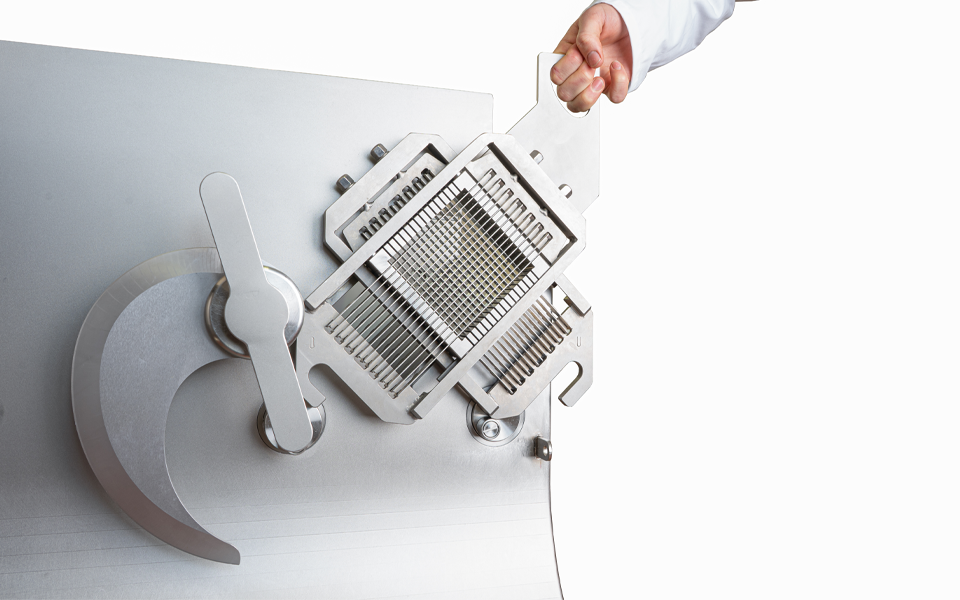

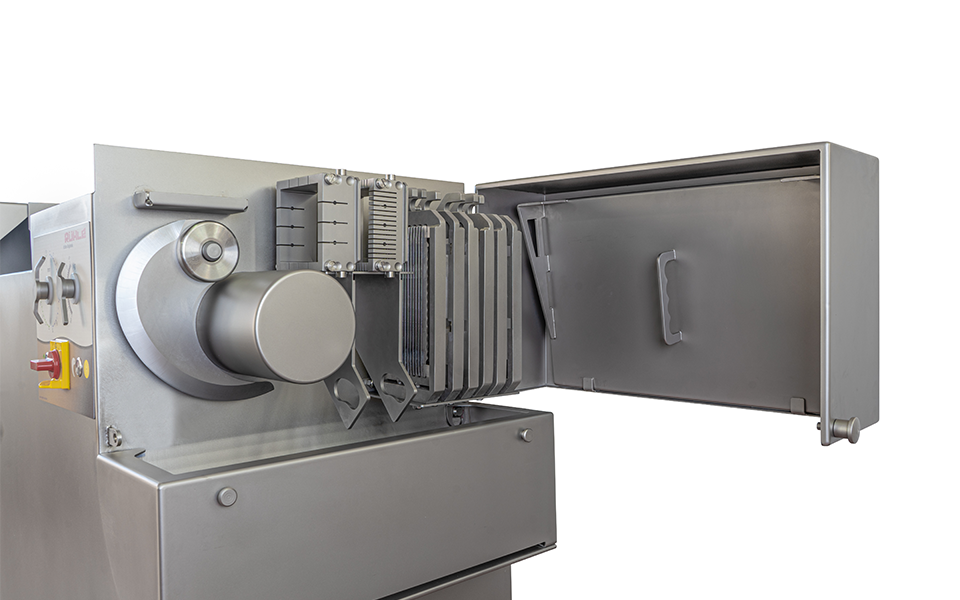

Special Features

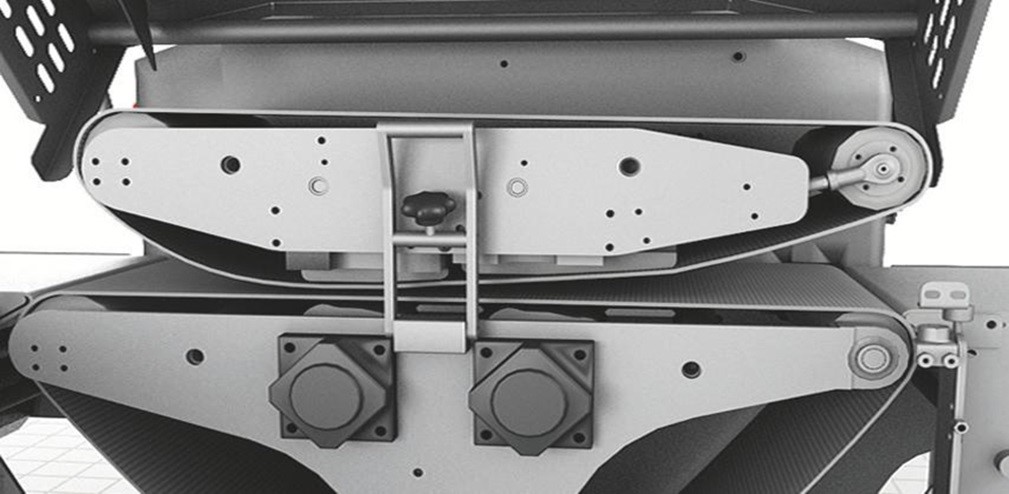

Technical Features

Productivity

Power

Water consumption

Weight

Additional information