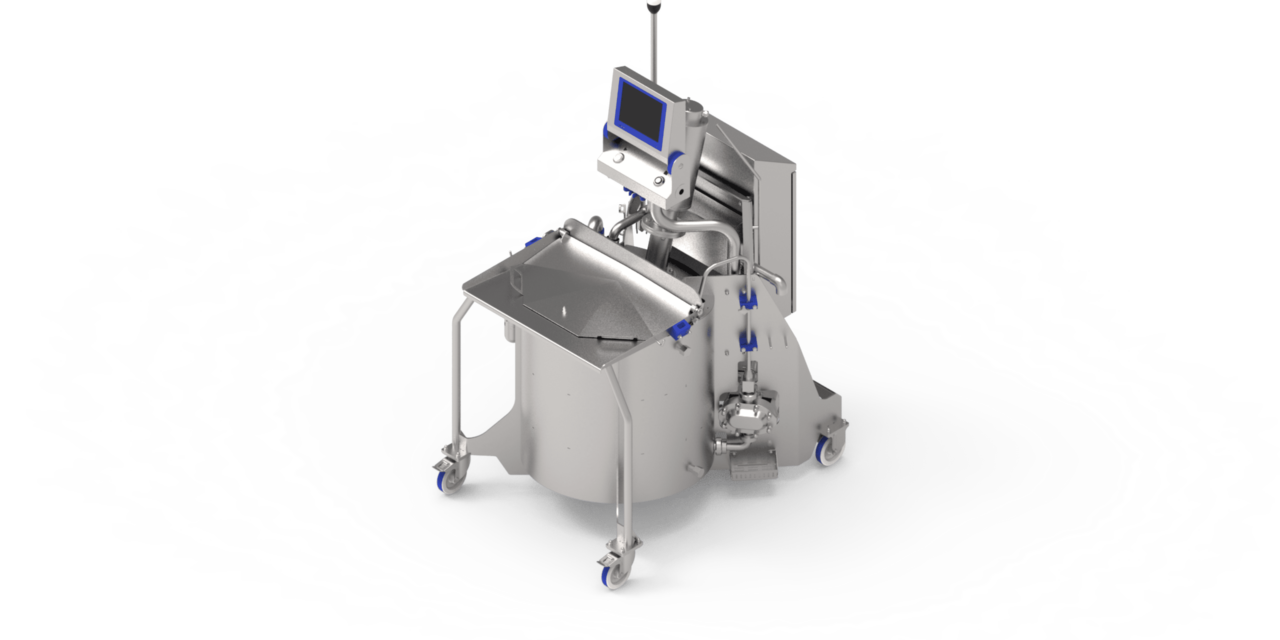

Vacuum machine 400 liters suitable for tumbling, mixing, marinating.

Special features

- Tablet control

- 100% container insulation

- Automated lid

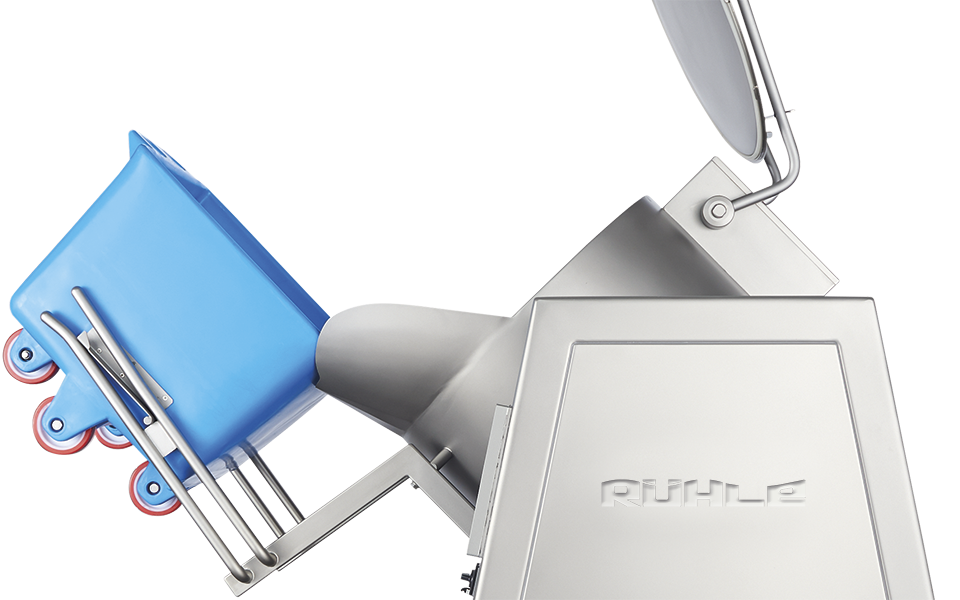

- Container swiveling

- Direct cooling system

- Stainless steel vacuum canal, cooled

- Feed system

- Counter – rotating mixing arm

- Quick arm fastening

- Scraper, pressure assembling

Technical Specifications

Additional information