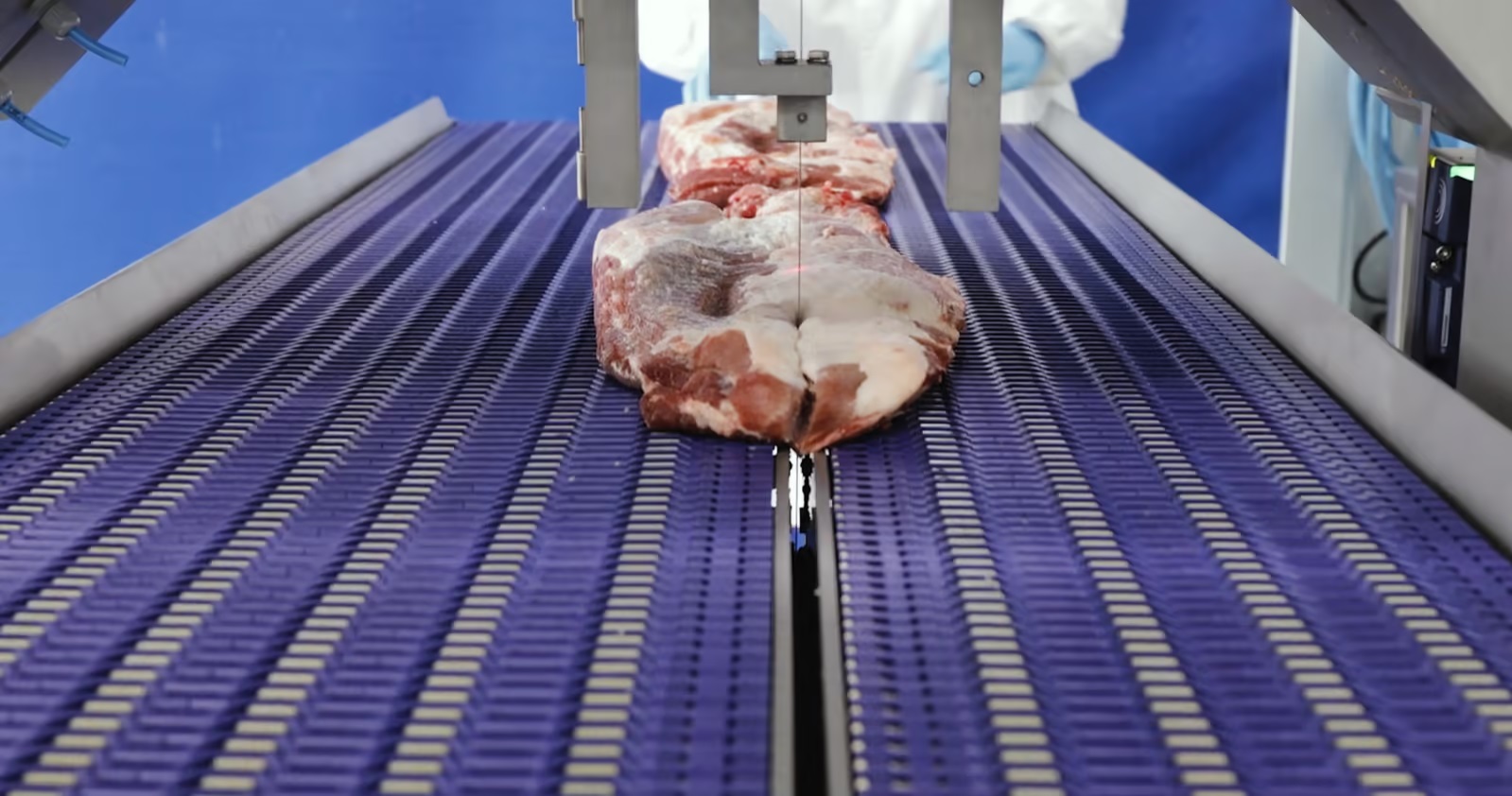

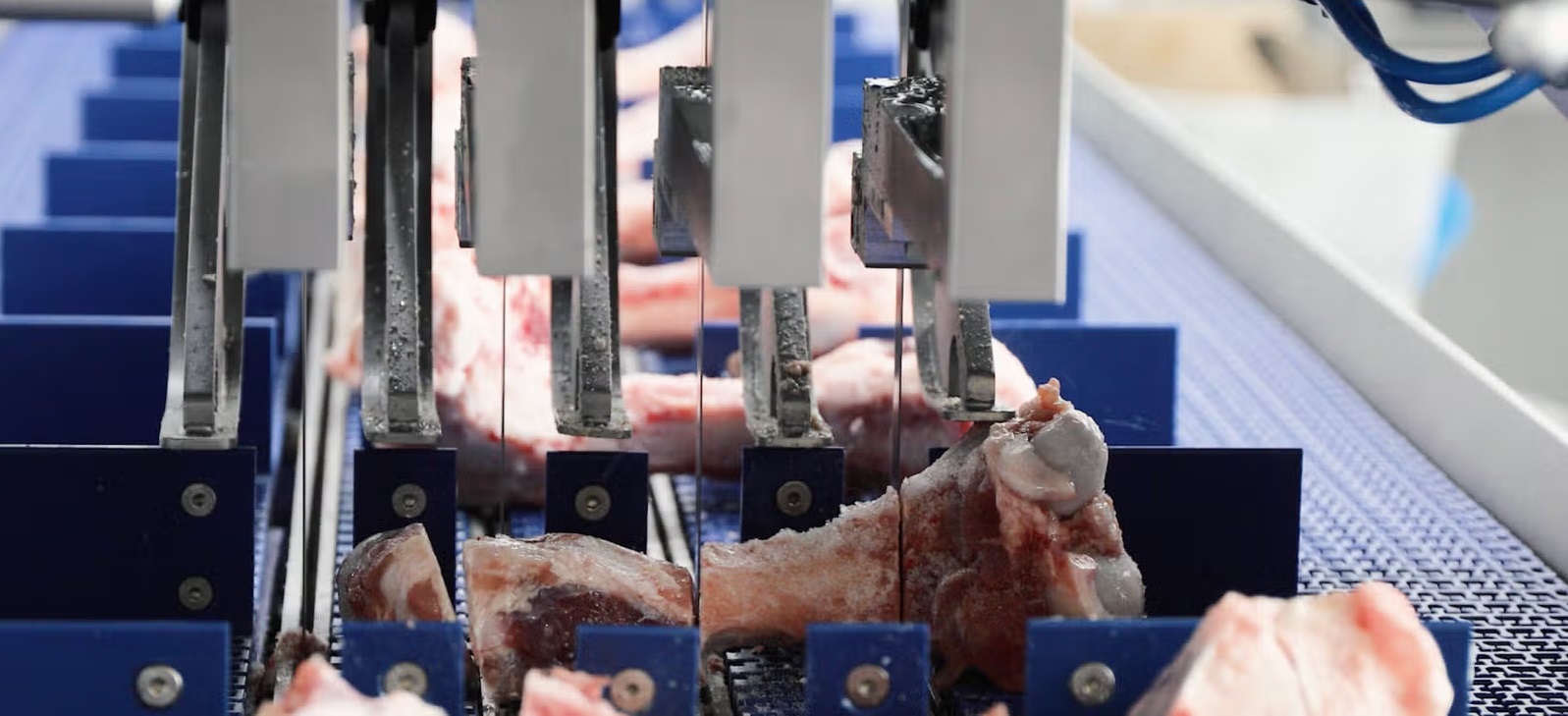

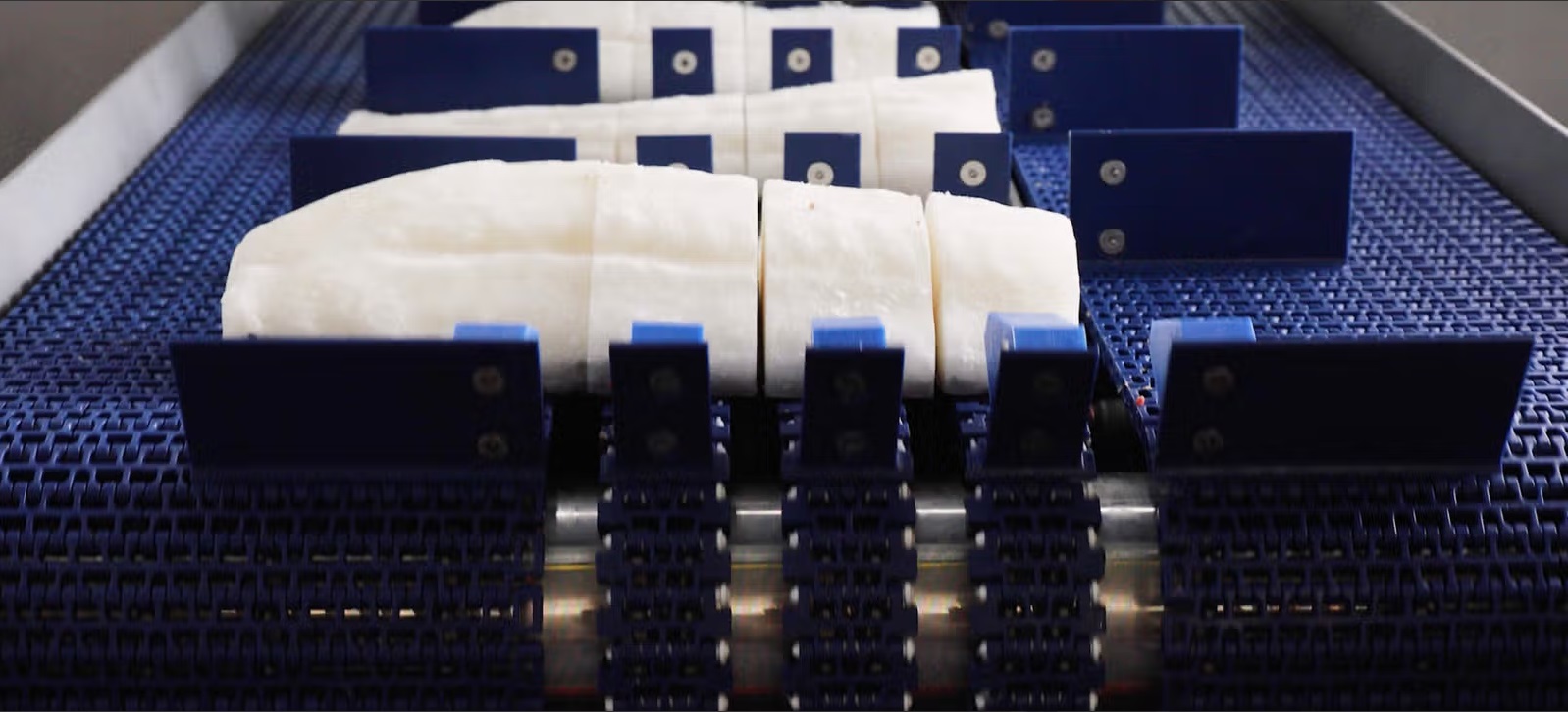

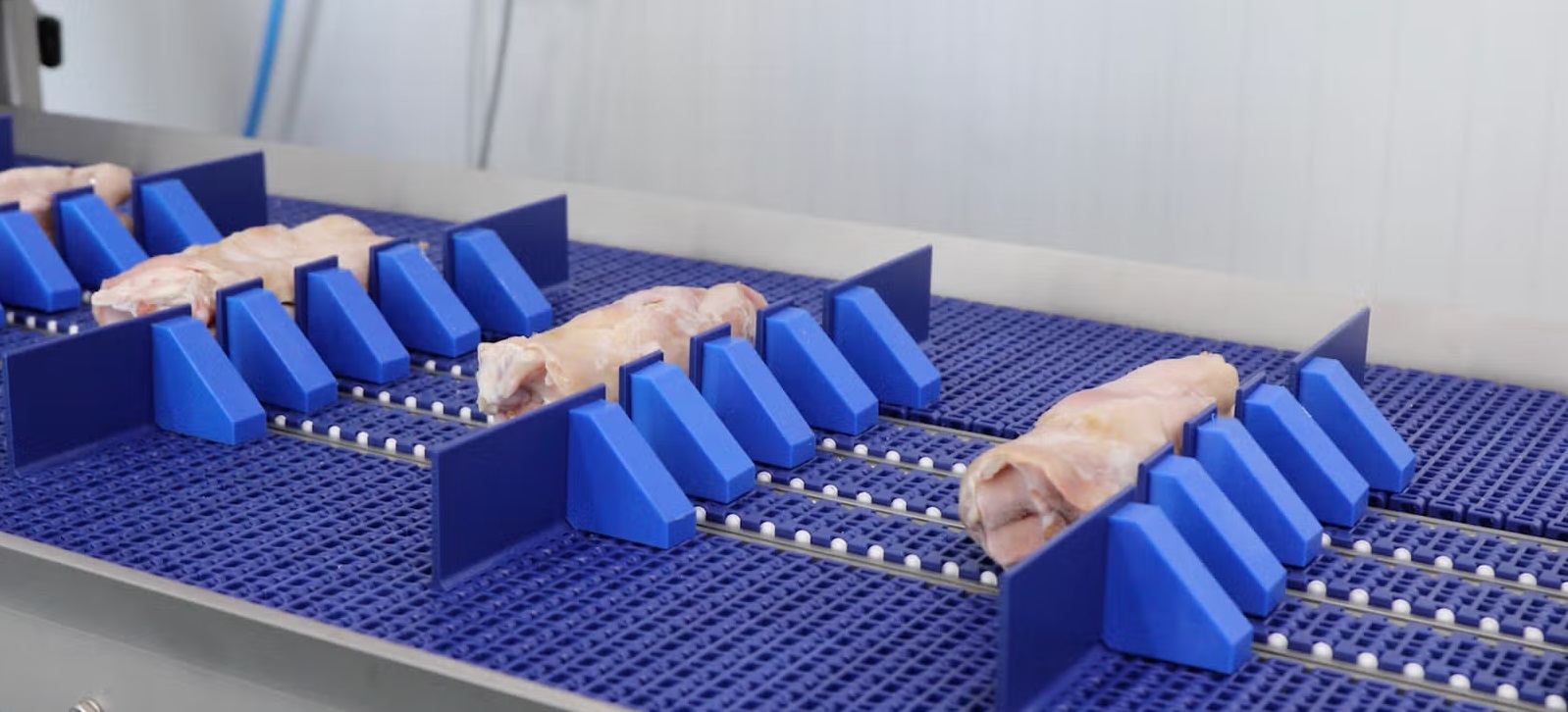

M2 series is both hygienic in production and easy to clean and offers various sizes of injectors depending on width of the transport systems Intuitive settings of pump pressure and production speed together with a constant read-out of brine temperature allows for precise and optimum food production.

- Accurate injection minimal return brine

- Maximum control

- Consistent brine distribution

- No blocked needles

- Hygienic design

- User friendly control panel

- Customized applications

|

FGM 26 M2

|

| Number of needles |

26 single, double or quadro

|

| Needle head |

20-90 Srokes per min.

|

| Trasnport system |

Conveyor belt – stainless steel or plastic (PEHD, Intralox) |

| Transport system (width) |

350 mm

|

| Product movement |

30 mm and 50 mm per stroke

|

| Stroke height (max) |

230 mm

|

| Product height (max) |

200 mm

|

| Weight |

700 kg

|

|

FGM 44 M2

|

| Number of needles |

44 single, double or quadro

|

| Needle head |

20-90 Srokes per min.

|

| Trasnport system |

Conveyor belt – stainless steel or plastic (PEHD, Intralox) |

| Transport system (width) |

575 mm

|

| Product movement |

30 mm and 50 mm per stroke

|

| Stroke height (max) |

230 mm

|

| Product height (max) |

200 mm

|

| Weight |

780 kg

|

|

FGM 54 M2

|

| Number of needles |

54 single, double or quadro

|

| Needle head |

20-90 Srokes per min.

|

| Trasnport system |

Conveyor belt – stainless steel or plastic (PEHD, Intralox) |

| Transport system (width) |

700 mm

|

| Product movement |

30 mm and 50 mm per stroke

|

| Stroke height (max) |

230 mm

|

| Product height (max) |

200 mm

|

| Weight |

850 kg

|