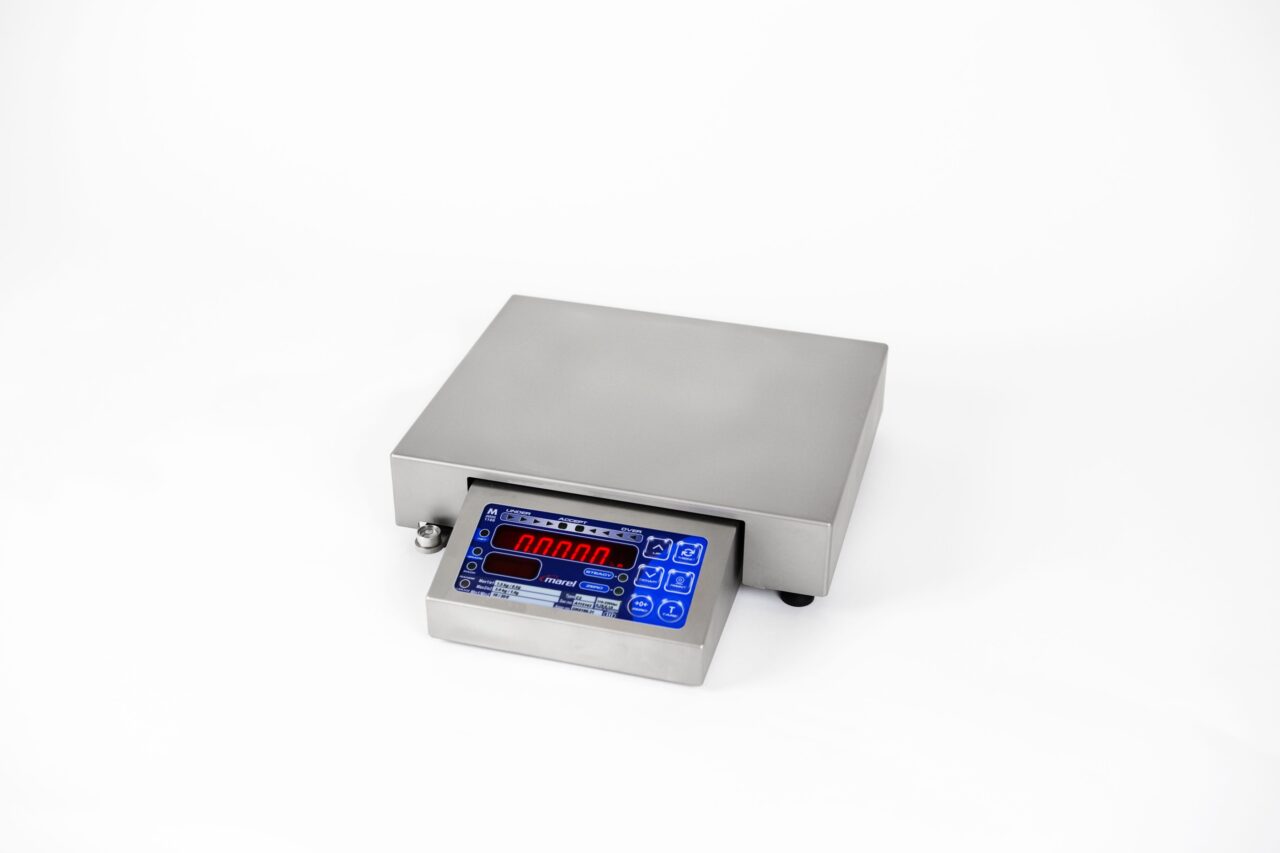

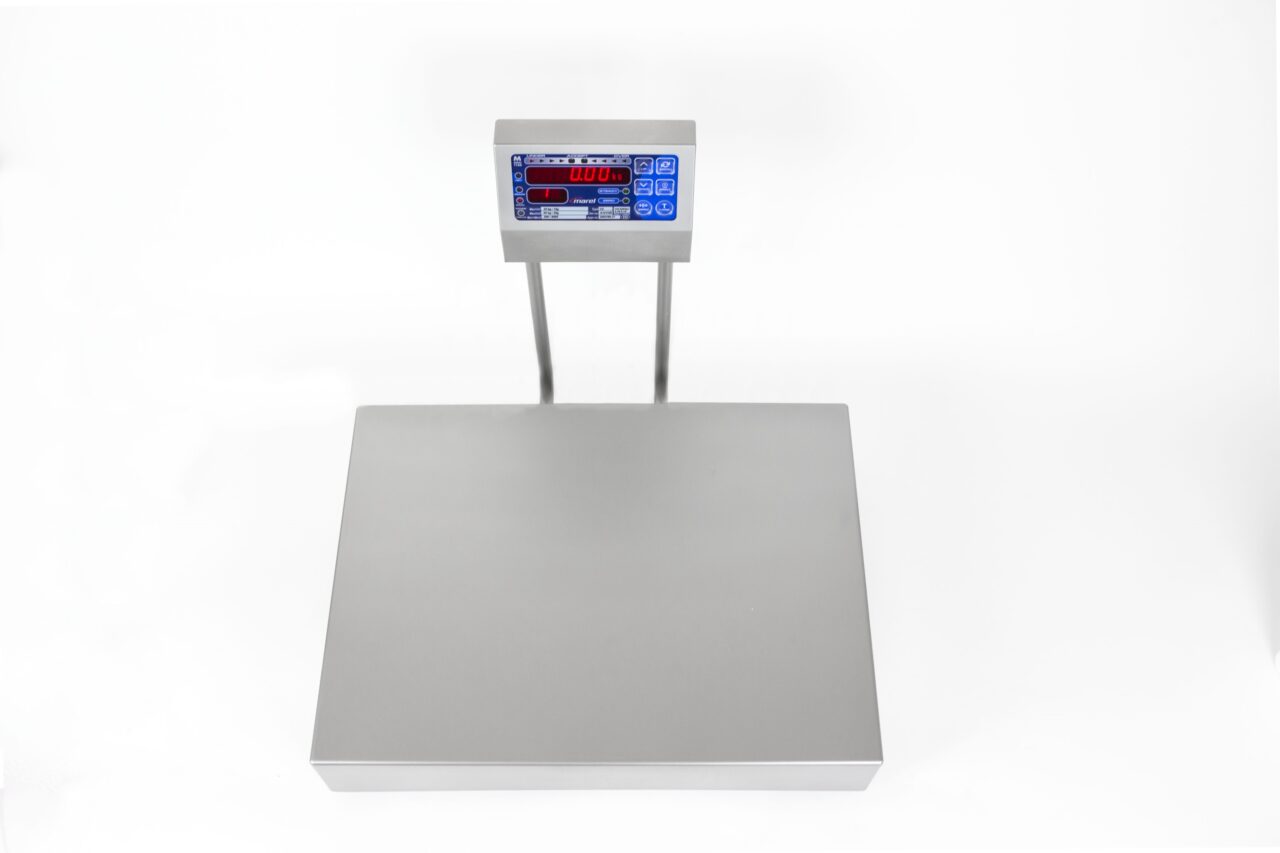

The Marel standard bench scales are suitable for all food processing industries in wet and dry environments. The scales are certifiable and can handle multiple weighing jobs. The M1100 series can help you monitor your process, lowering your give-away, increasing your yields, and ensuring better production control.

- Capable of accurately registering and recording weights in 0.5-1.0 seconds

- Water-resistant to IP67/IP69K standards

- Designed for minimal maintenance

- M1100 easy to read indicator

- Power supply: Mains, DC, and battery version.

- Weighing capacity up to 300 kg

- Platform dimensions from 250x178mm to 500x600mm

- Accuracy from 0,5g

| Version |

PL 1000

|

PL 2020 |

PL 2062 |

PL 3020 |

PL 4020 |

PL 4026 |

PL 5020

|

| Dimensions |

250×178 mm

|

246×296 mm |

292×242 mm |

296×396 mm |

400×550 mm |

400×600 mm |

500×600 mm

|

| Type |

| Short pillar |

x

|

x |

|

x |

|

|

|

| Long pillar |

x

|

x |

|

x |

x |

x |

x

|

| Wallmount |

x

|

x |

|

x |

x |

x |

x

|

| Portable |

|

|

x |

|

|

|

|

| Weighing range accuracy |

| 1,5-3kg(0,5-1g) |

x

|

x |

x |

|

|

|

|

| 3-6kg(1-2g) |

|

x |

x |

|

|

|

|

| 6-15kg(2-5g) |

|

x |

x |

x |

|

|

|

| 15-30kg(5-10g) |

|

|

|

x |

|

x |

x

|

| 30-60kg(10-20g) |

|

|

|

|

x |

|

x

|

| 60-150kg(20-50g) |

|

|

|

|

|

|

x

|

| 150-300kg(50-100g) |

|

|

|

|

|

|

x |

|

PL 1000 |

|

| Dimensions |

250×178 mm |

|

| Type |

| Short pillar |

x |

|

| Long pillar |

x |

|

| Wallmount |

x |

|

| Portable |

|

|

| Weighing range accuracy |

| 1,5-3kg(0,5-1g) |

x |

|

|

PL 2020

|

|

| Dimensions |

246×296 mm

|

|

| Type |

| Short pillar |

x

|

|

| Long pillar |

x

|

|

| Wallmount |

x

|

|

| Portable |

|

|

| Weighing range accuracy |

| 1,5-3kg(0,5-1g) |

x

|

|

| 3-6kg(1-2g) |

x

|

|

| 6-15kg(2-5g) |

x

|

|

|

PL 2062

|

|

| Dimensions |

292×242 mm

|

|

| Type |

| Short pillar |

|

|

| Long pillar |

|

|

| Wallmount |

|

|

| Portable |

x

|

|

| Weighing range accuracy |

| 1,5-3kg(0,5-1g) |

x

|

|

| 3-6kg(1-2g) |

x

|

|

| 6-15kg(2-5g) |

x

|

|

|

PL 3020

|

|

| Dimensions |

296×396 mm

|

|

| Type |

| Short pillar |

x

|

|

| Long pillar |

x

|

|

| Wallmount |

x

|

|

| Portable |

|

|

| Weighing range accuracy |

| 1,5-3kg(0,5-1g) |

|

|

| 3-6kg(1-2g) |

|

|

| 6-15kg(2-5g) |

x

|

|

| 15-30kg(5-10g) |

x

|

|

|

PL 4020

|

|

| Dimensions |

400×550 mm

|

|

| Type |

| Short pillar |

|

|

| Long pillar |

x

|

|

| Wallmount |

x

|

|

| Portable |

|

|

| Weighing range accuracy |

| 1,5-3kg(0,5-1g) |

|

|

| 3-6kg(1-2g) |

|

|

| 6-15kg(2-5g) |

|

|

| 15-30kg(5-10g) |

|

|

| 30-60kg(10-20g) |

x

|

|

| Versions |

PL 4026

|

|

| Dimensions |

400×600 mm

|

|

| Type |

| Short pillar |

|

|

| Long pillar |

x

|

|

| Wallmount |

x

|

|

| Portable |

|

|

| Weighing range accuracy |

| 1,5-3kg(0,5-1g) |

|

|

| 3-6kg(1-2g) |

|

|

| 6-15kg(2-5g) |

|

|

| 15-30kg(5-10g) |

x

|

|

| Versions |

PL 5020

|

|

| Dimensions |

500×600 mm

|

|

| Type |

| Short pillar |

|

|

| Long pillar |

x

|

|

| Wallmount |

x

|

|

| Portable |

|

|

| Weighing range accuracy |

| 1,5-3kg(0,5-1g) |

|

|

| 3-6kg(1-2g) |

|

|

| 6-15kg(2-5g) |

|

|

| 15-30kg(5-10g) |

x

|

|

| 30-60kg(10-20g) |

x

|

|

| 60-150kg(20-50g) |

x

|

|

| 150-300kg(50-100g) |

x

|

|