Forming machine PlateFormer

High pressure forming machine of Marel of a variety of convenience products such as: meat balls, schnitzels, burgers, nuggets and whole pieces.

Special Features

Additional information

High pressure forming machine of Marel of a variety of convenience products such as: meat balls, schnitzels, burgers, nuggets and whole pieces.

Special Features

Additional information

The TG9 Tray Grader grades trays by fixed count, fixed weight or a combination of both.

Special Features

Additional information

System suitable for diverting the trays into fixed weight, fixed count or combination of both.

Special Features

Additional information

The Multi-Lane converger is suitable for converging products from multiple lines into one. Fully adjustable from 2 to six lines.

Special Features

Additional information

The Pack Turner turns packs to wide-edge leading to ensure the correct presentation when the pack reaches a labeler. This auxiliary unit integrates easily into a packing line, reducing manual handling and increasing line efficiency.

Additional information

MCheck 2 combines high levels of accuracy with flexibility and capacity, making it the ideal choice for any food processing company–both in wet and dry production environments and end-of-line applications.

150 packs/min up to 80 m/min 40-6000 kg 80x50x10 mm 589x350x125 mm 1,25 l/min 120 kg

Special Features

Technical Specifications

Productivity

Belt Speed

Weighing range

Minimum pack dimensions (LxWxH)

Maximim pack dimensions (LxWxH)

Air consumption

Weight

Additional information

Low pressure forming machine of Marel forfor producing products of uniform shape and accurate weight with high quality and productivity.

Special Features

Additional information

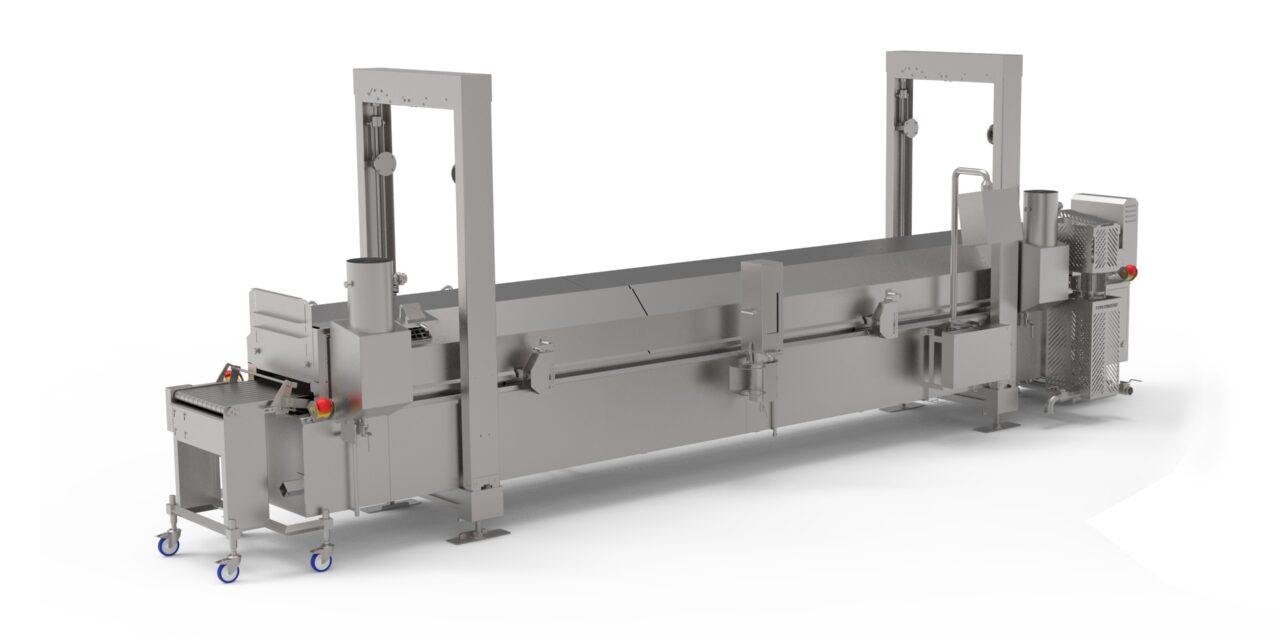

GoldFryer produces a beautifully fried end product with an attractive color, perfect coating adhesion and enhanced taste and texture. The oil flow in the GoldFryer has the highest circulation speed in the industry. This ensures a highly stable frying environment and maximum transfer of heat to products.

Special Features

Additional information

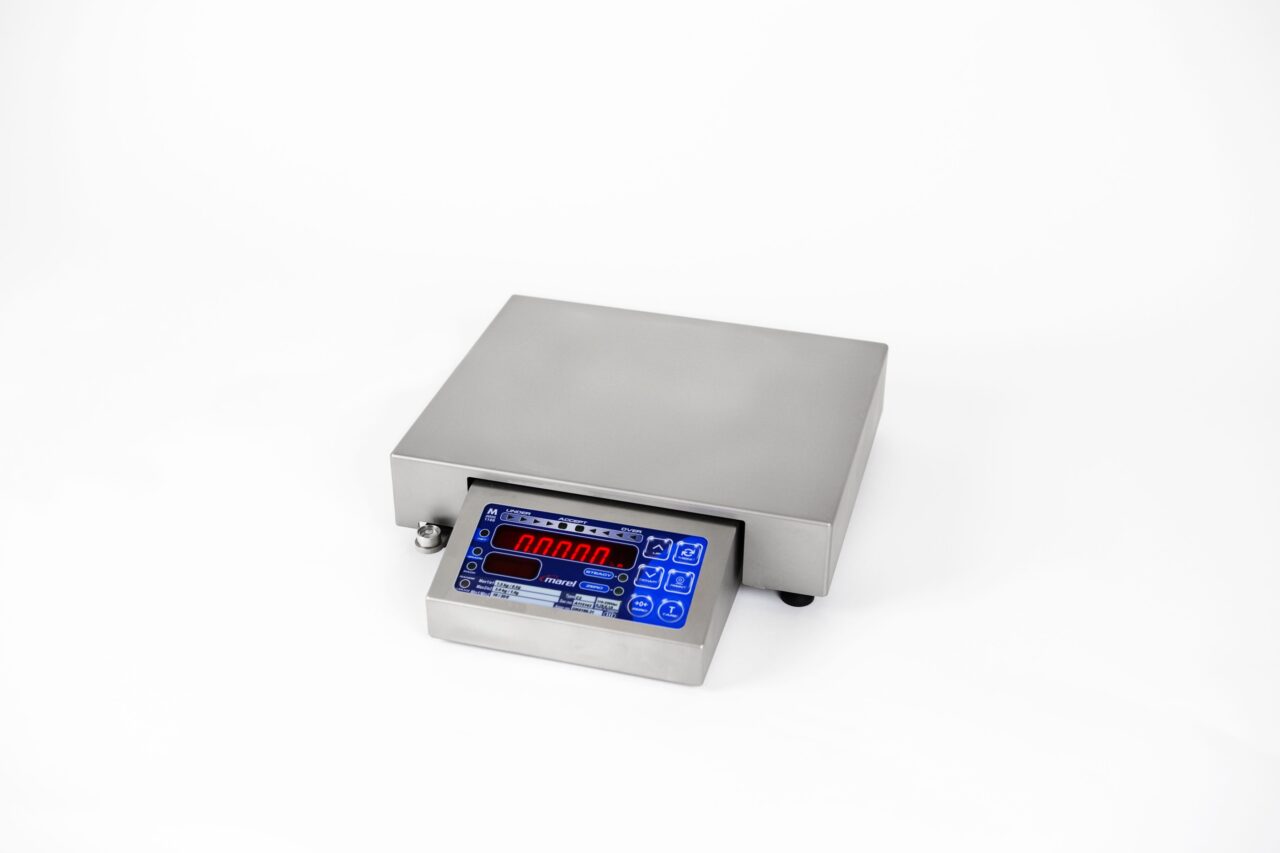

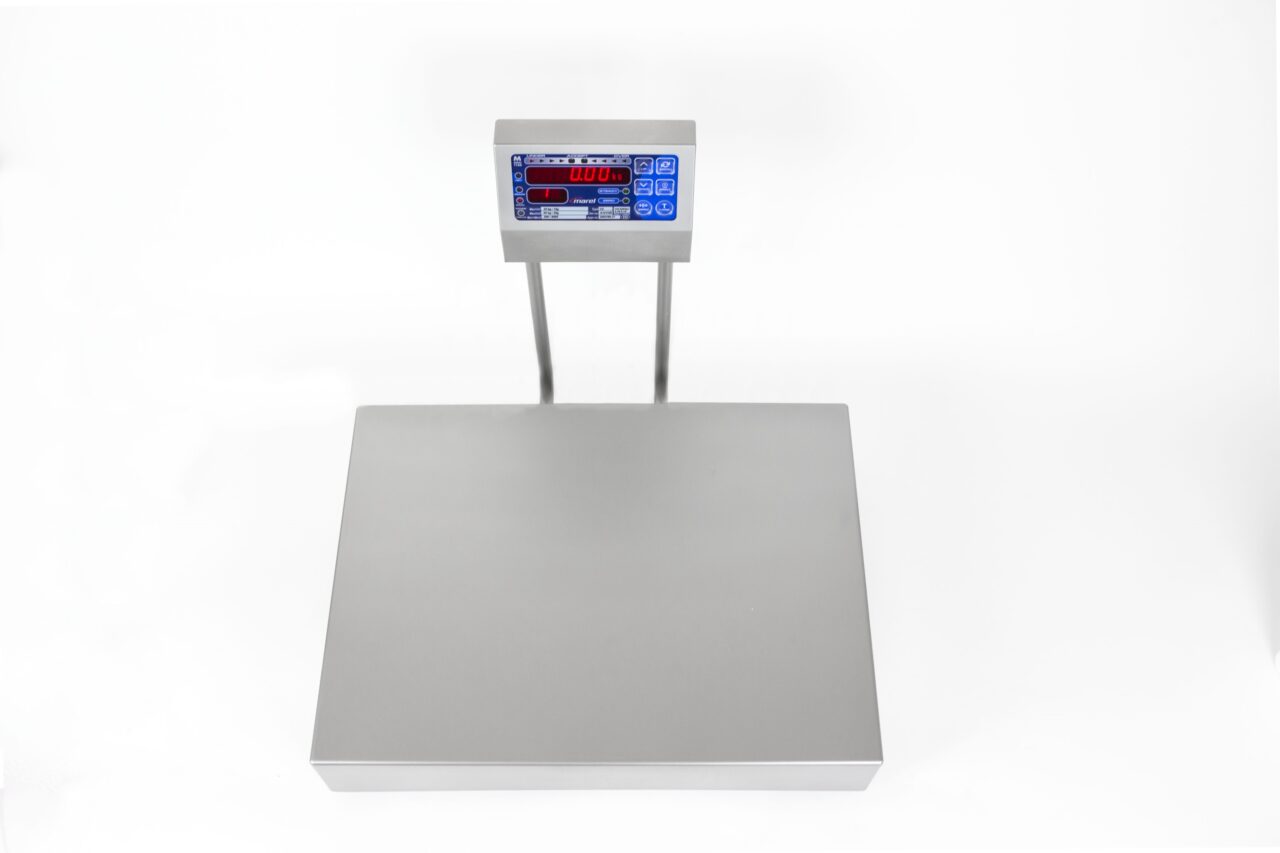

The Marel standard bench scales are suitable for all food processing industries in wet and dry environments. The scales are certifiable and can handle multiple weighing jobs. The M1100 series can help you monitor your process, lowering your give-away, increasing your yields, and ensuring better production control.

PL 1000 PL 5020 250×178 mm 500×600 mm x

x x x x

x

x

x

x

PL 2020 246×296 mm x x x x x x

PL 2062 292×242 mm x x x x

PL 3020 296×396 mm x x x x x

PL 4020 400×550 mm x x x

PL 4026 400×600 mm x x x

PL 5020 500×600 mm x x x x x x

Special Features

Versions

Version

PL 2020

PL 2062

PL 3020

PL 4020

PL 4026

Dimensions

246×296 mm

292×242 mm

296×396 mm

400×550 mm

400×600 mm

Type

Short pillar

x

x

Long pillar

x

x

x

x

Wallmount

x

x

x

x

Portable

x

Weighing range accuracy

1,5-3kg(0,5-1g)

x

x

3-6kg(1-2g)

x

x

6-15kg(2-5g)

x

x

x

15-30kg(5-10g)

x

x

30-60kg(10-20g)

x

60-150kg(20-50g)

150-300kg(50-100g)

x

Versions

PL 1000

Dimensions

250×178 mm

Type

Short pillar

x

Long pillar

x

Wallmount

x

Portable

Weighing range accuracy

1,5-3kg(0,5-1g)

x

Dimensions

Type

Short pillar

Long pillar

Wallmount

Portable

Weighing range accuracy

1,5-3kg(0,5-1g)

3-6kg(1-2g)

6-15kg(2-5g)

Dimensions

Type

Short pillar

Long pillar

Wallmount

Portable

Weighing range accuracy

1,5-3kg(0,5-1g)

3-6kg(1-2g)

6-15kg(2-5g)

Dimensions

Type

Short pillar

Long pillar

Wallmount

Portable

Weighing range accuracy

1,5-3kg(0,5-1g)

3-6kg(1-2g)

6-15kg(2-5g)

15-30kg(5-10g)

Dimensions

Type

Short pillar

Long pillar

Wallmount

Portable

Weighing range accuracy

1,5-3kg(0,5-1g)

3-6kg(1-2g)

6-15kg(2-5g)

15-30kg(5-10g)

30-60kg(10-20g)

Versions

Dimensions

Type

Short pillar

Long pillar

Wallmount

Portable

Weighing range accuracy

1,5-3kg(0,5-1g)

3-6kg(1-2g)

6-15kg(2-5g)

15-30kg(5-10g)

Versions

Dimensions

Type

Short pillar

Long pillar

Wallmount

Portable

Weighing range accuracy

1,5-3kg(0,5-1g)

3-6kg(1-2g)

6-15kg(2-5g)

15-30kg(5-10g)

30-60kg(10-20g)

60-150kg(20-50g)

150-300kg(50-100g)

Additional information

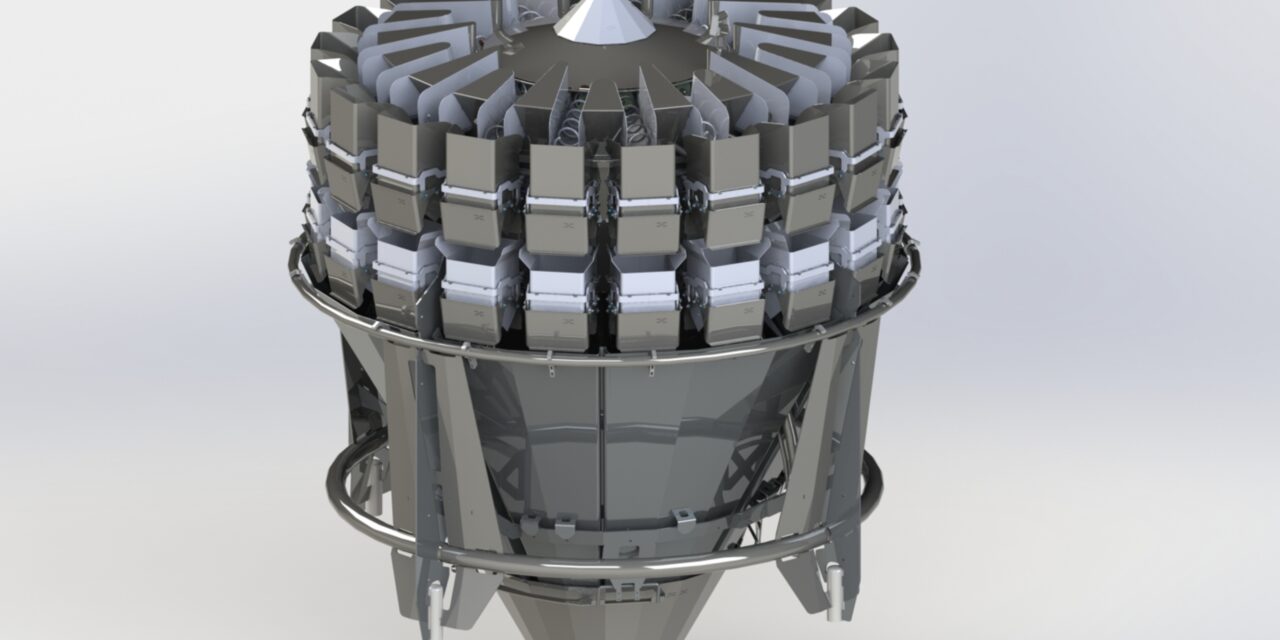

Marel Multi-Head Weigher suitable for weighing products, creating portions of constant weight and placing them securely to the next stage of the production process.

Special Features

Additional information