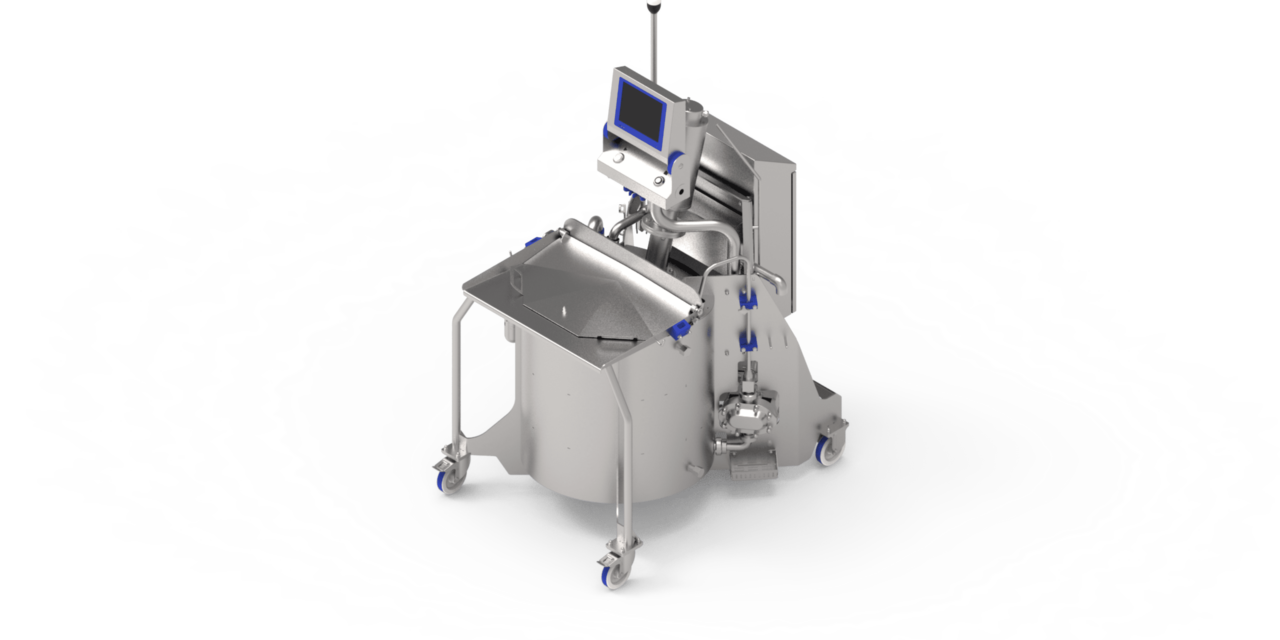

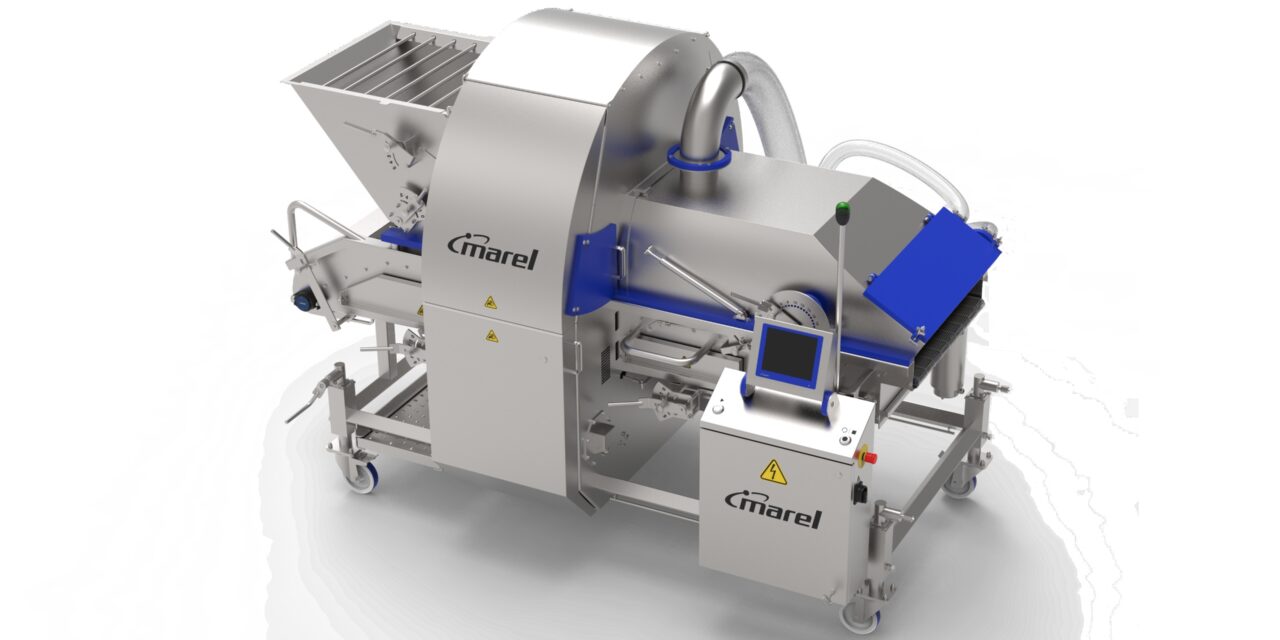

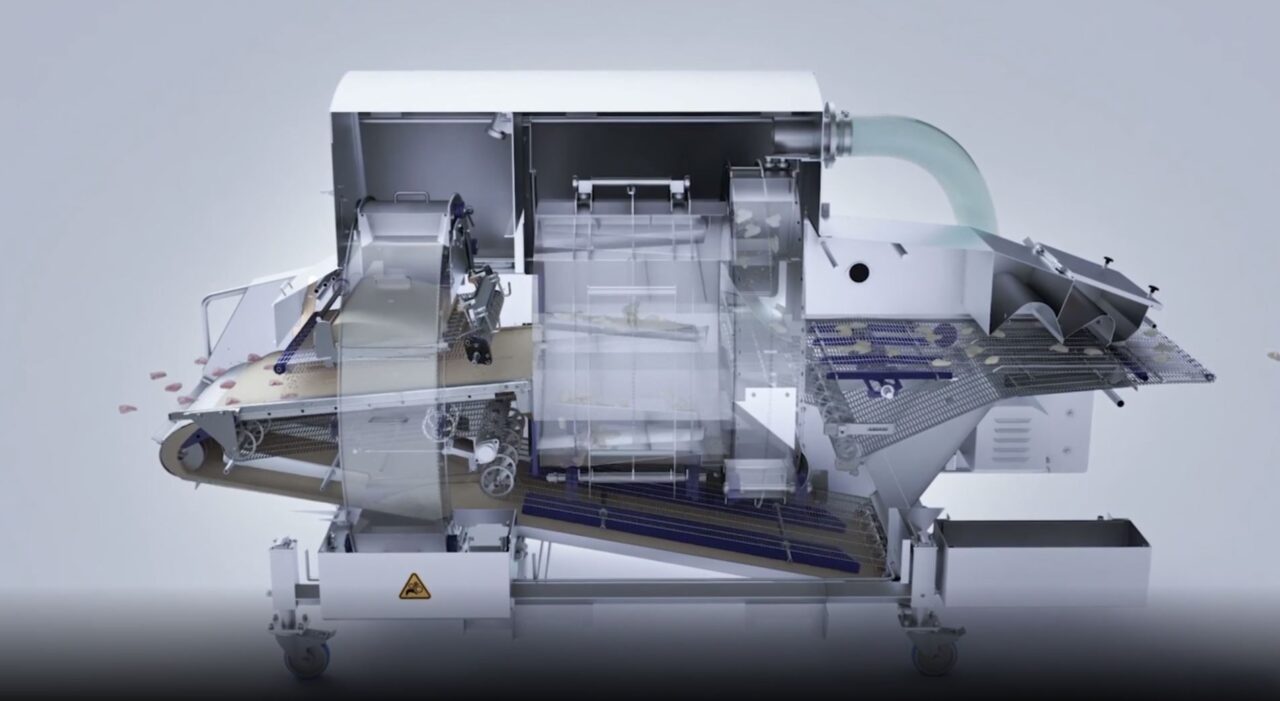

F-LINE F40, F52 and F60 are the entry-level models in the vacuum. Suitable for connection with all additional equipment for the production of burgers, sausages and other meat products. The vacuum pump is sucking off resting air bubbles (gaps) from the product. You get a perfect sausage aspect – the subsequent natural reddening is improved.

- Made entirely of stainless steel

- 150 filling programs

- For straight filling and dosing

- Speed and pause lengths are infinitely variable

- Flow measurement, piece counter, count-based auto stop

- Flow-reverse mechanism and adjustable 1st portion weight

| F-LINE |

F-40 |

F-52 |

F-60 |

| Capacity |

40 l |

25/90 l |

25/90 l |

| Max.performance |

1900 kg/h |

2500 kg/h |

2900 kg/h |

| Filling Pressure up to |

30 bar |

40 bar |

40 bar |

| Chamber capacity |

82 g |

82 g |

82 g |

| Filling chambers |

8 |

8 |

8 |

| Portioning range |

0,1-99.999g |

0,1-99.999g |

0,1-99.999g |

| Power Supply |

3Ph./PE, 400V, 50/60Hz |

3Ph./PE, 400V, 50/60Hz |

3Ph./PE, 400V, 50/60Hz |

| Sucking power of vacuum pump |

16 m/h |

16 m/h |

16 m/h |

| Weight |

380 Kg |

430 Kg |

430 Kg |

| Portioning speed max. |

300 port/min. |

450 port/min. |

530 port/min. |

| F-LINE |

F-40

|

| Capacity |

40 l

|

| Max.performance |

1900 kg/h

|

| Filling Pressure up to |

30 bar

|

| Capacity of the chambers |

82 g

|

| Filling chambers |

8

|

| Portioning range |

0,1-99.999 g

|

| F-LINE |

F-52

|

| Capacity |

25/90 l

|

| Max.performance |

2500 kg/h

|

| Filling Pressure up to |

40 bar

|

| Capacity of the chambers |

82 g

|

| Filling chambers |

8

|

| Portioning range |

0,1-99.999 g

|

| F-LINE |

F-60

|

| Capacity |

25/90 l

|

| Max.performance |

2900 kg/h

|

| Filling Pressure up to |

40 bar

|

| Capacity of the chambers |

82 g

|

| Filling chambers |

8

|

| Portioning range |

0,1-99.999 g

|