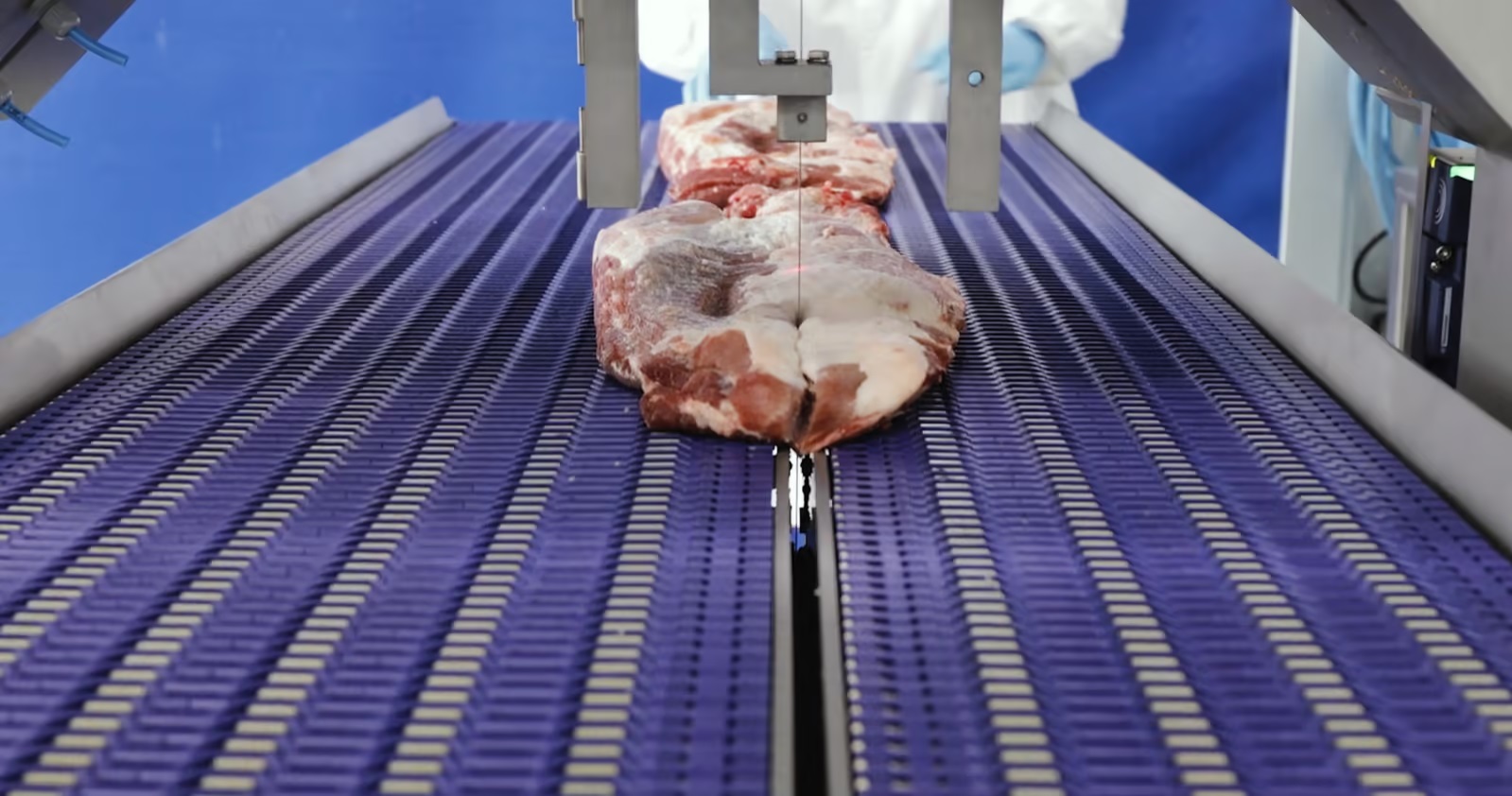

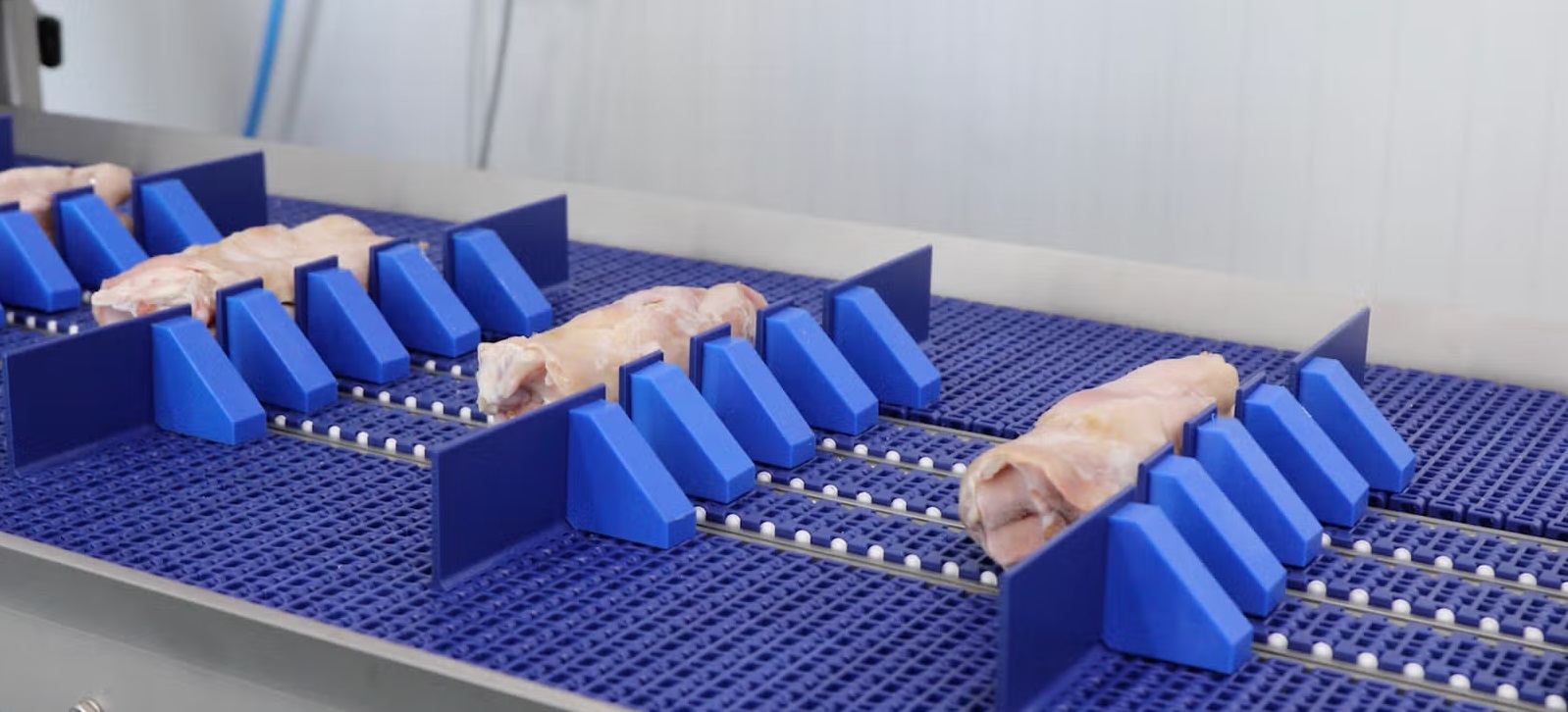

The Horizontal Slicer MSC 650-45 is a slicer capable of horizontal cutting suitable for salmon and other fish species similar in size and texture. It is single line and can handle fresh and smoked products providing flexibility.

120 kg/h Horizontal 45 mm 230 mm 650 mm from 1,8 mm 1,3 kW 2700x900x1200 mm 340 kg

Special Features

Technical Specifications

Maximum machine capacity

Cutting angle

Max. product height

Max cutting width:

Max. cut-off length

Cutting width

Power

Dimensions (LxWxH)

Weight

Additional information