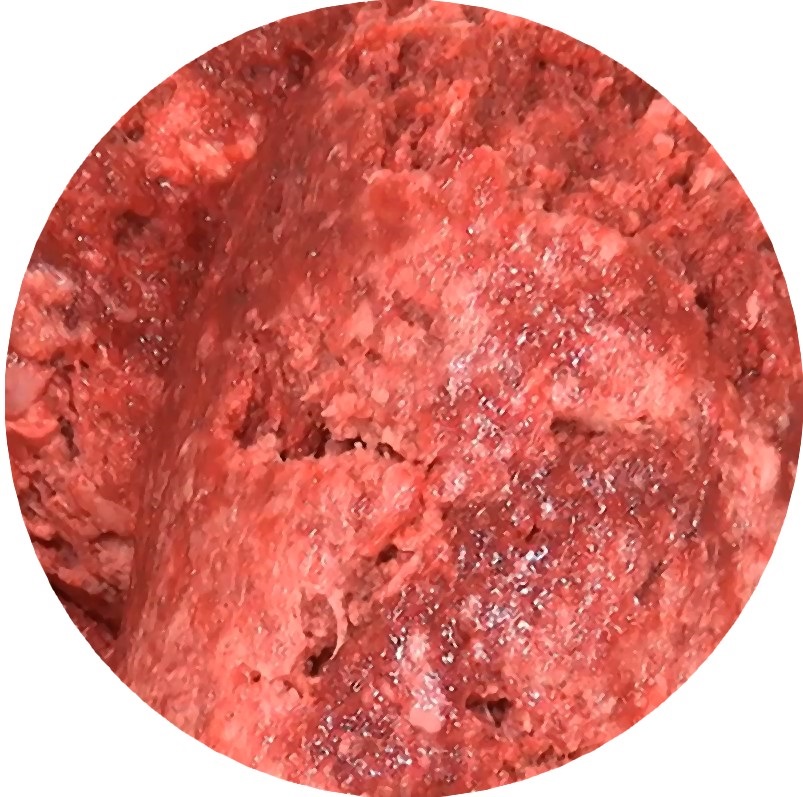

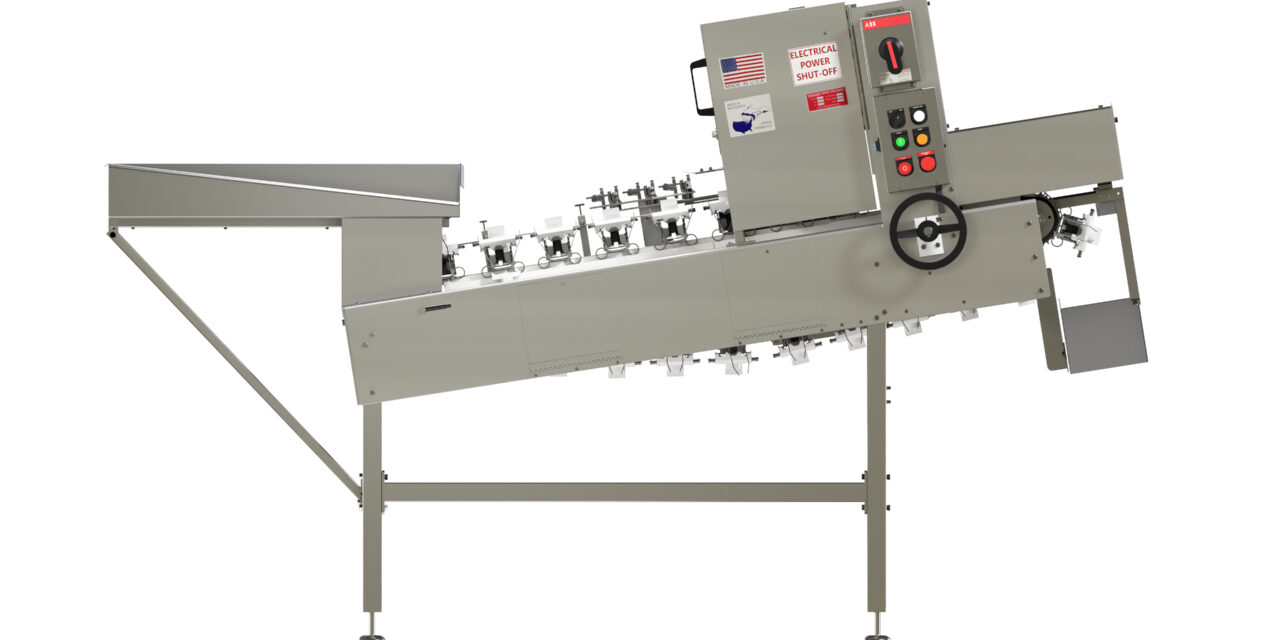

The DD/DDS DDM/DDSM series machines are specially designed for grinding and de-tissueing red meat (boneless) raw material, such as boneless beef shanks, tendons or other cuts of meat. During the process, optimal performance is achieved with high technical characteristics and sanitary process. The D/DDS DDM/DDSM model range is equipped with a pre-breaking arm system which enables to feed the hopper with raw materials of big dimension without having to pre-cut them. LIMA offers 84 different models from 100 to 113.000 kg/hr to match each customer’s product type and performance.

Special features

Additional information