High capacity D-Cutting machine for salmon suitable for fresh or smoked salmon fillets. and other fish species similar in size and texture.

Special Features

Additional information

High capacity D-Cutting machine for salmon suitable for fresh or smoked salmon fillets. and other fish species similar in size and texture.

Special Features

Additional information

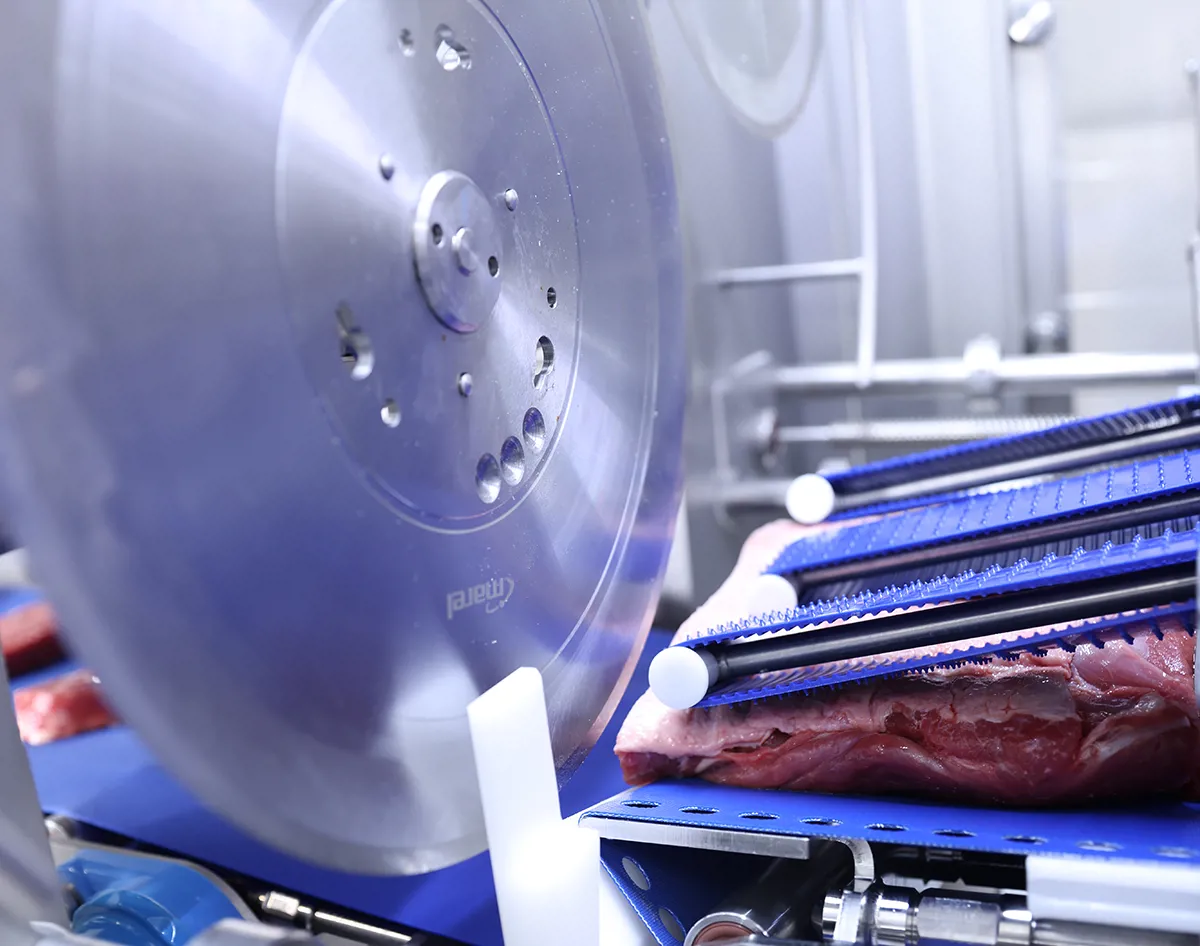

The I-CUT 360 is suitable for processing non-frozen meat products to fixed weight and/or uniform dimensions. The Marel cutting machine offers high speed and precision in combination with modern cutting processing software. The I Cut 360 is a flexible tool suitable for all needs and throughputs.

Special Features

Technical Specifications

Lenght

3510 mm

Width

1410 mm

Height

1865 mm

Footprint

4.9 m²

Weight

1200 kg

Additional information

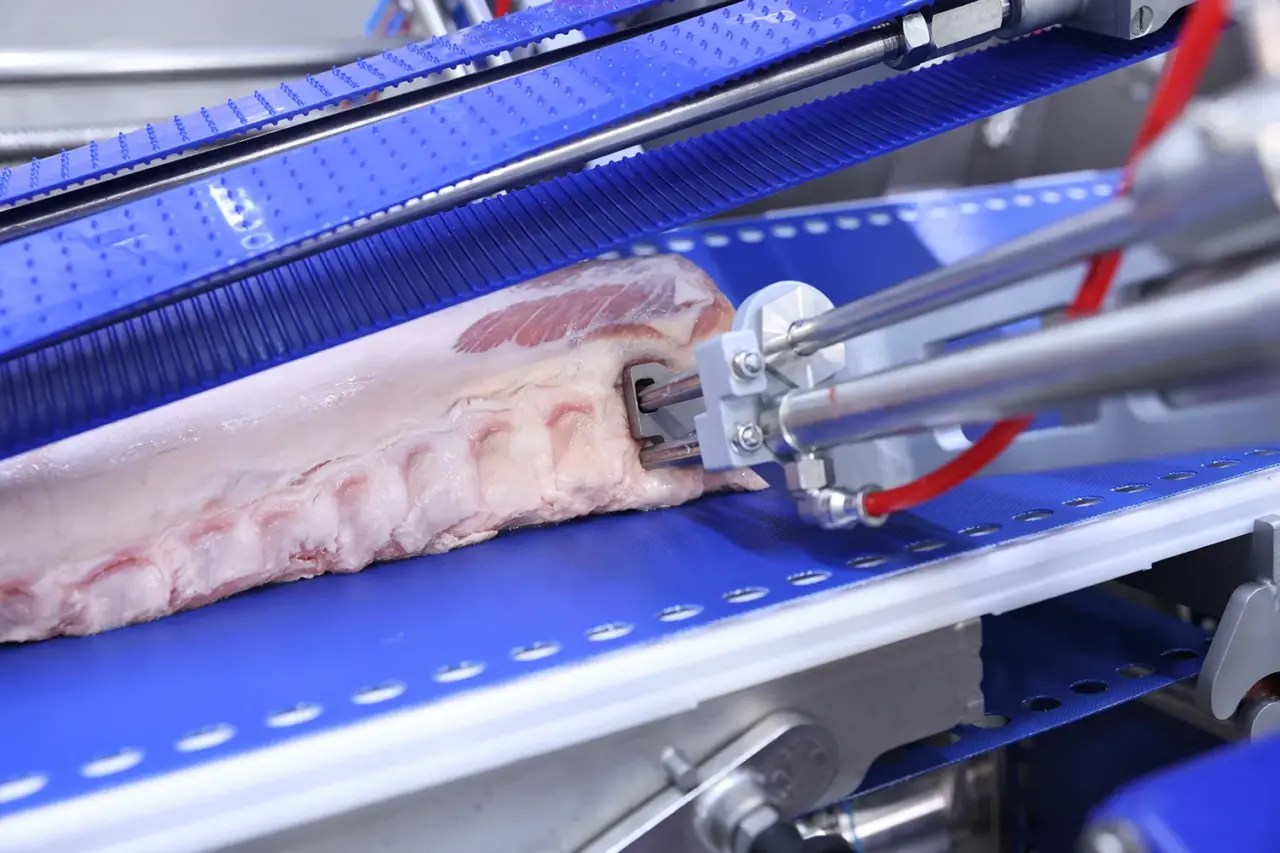

Cutting machine suitable for portion cutting into fixed weight or thickness, for bone-in or boneless products.

up to 500 kg/h 2760x1200x2300 mm 1650 kg 70 m/s 6 80 l/min, 60 bar

Special Features

Technical Specifications

Productivity

Housing dimensions (LxWxH)

Weight

Blade speed

Product magazines

Air supply

Additional information

Cutting machine for salmon. It pre-slices whole sides of fresh or smoked salmon fillets and similar products and has a cutting angle of 10°-68° or 8°- 66°.

130 kg/h 8 ο – 68 ο 250 mm from 2 mm 1,8 kW 3640x980x1485 mm 720 kg 8 bar

Special Features

Technical Specifications

Maximum machine capacity

Cutting angle

Max. slice length

Cutting width

Power

Dimensions (LxWxH)

Weight

Air supply

Additional information

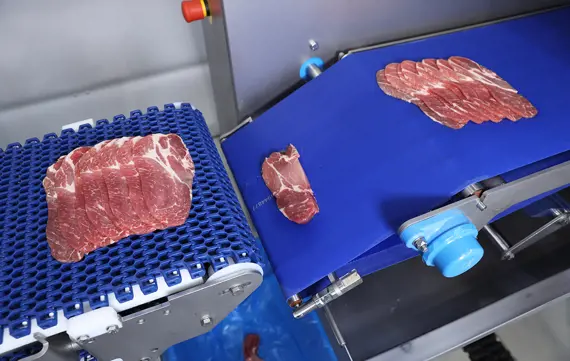

Versatile application The circular blade cutting machine STC 400 is suitable for a big variety of slicing applications, e.g. slicing of fresh boneless poultry cuts from broilers, turkey and duck. User friendly operation Large choice of cutting rollers Short setup times for high operational availability High safety standards

Technical Specifications

Total cutting width

283 mm

Max. product thickness

~95 mm depending on the product

Dimensions (LxWxH)

2185x766x1282 mm

Power

1,5 kW

Weight

265 kg

Additional information

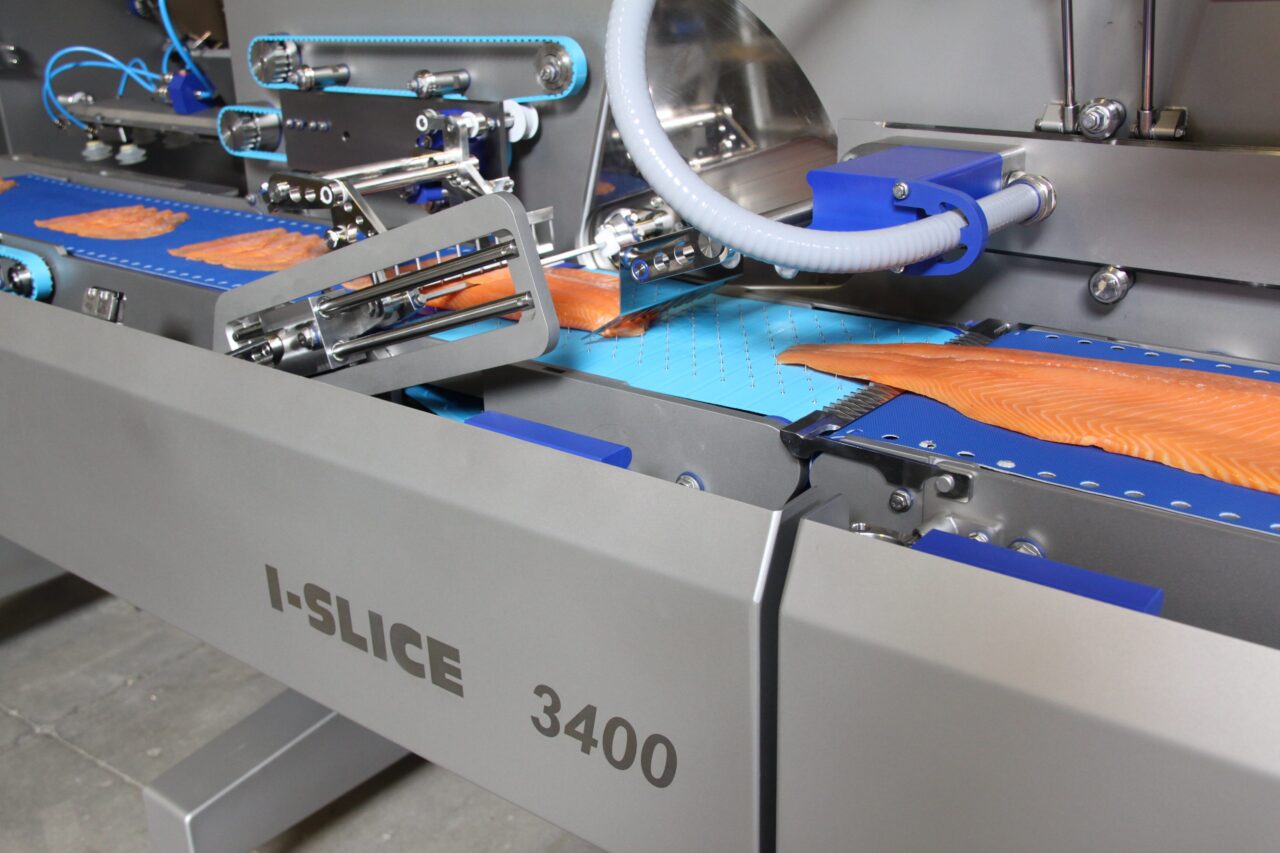

The I-Slice 3400 slices, and batches salmon and other fish species similar in weight and texture to fit every pack’s size and weight. The salmon fillets are first weighed and scanned to calculate optimal utilization. Each slice is then cut to match the defined target weight, and the slices are aligned in accurate batches in accordance with the pack size.

90 kg/h 8 ο – 40 ο / 8 ο – 72 ο optional 200 mm 2 – 20 mm 750x250x60 mm 3,3 kW 3330x1380x1610 mm 1050 kg 8 bar

90 – 60 mm 65 – 250 mm 40 mm

Special Features

Technical Specifications

Max. capacity

Cutting angle

Max. slice length

Cutting width

Max. fillet dimensions (LxWxH)

Power

Dimensions (LxWxH)

Weight

Air supply

Tray sizes

Standard length

Width

Βάθος

Additional information

After filleting, the MS 2920 QC Scanner scans each fillet to detect colour defects such as melanin, blood spots and cutting defects. The fillets are then sorted according to preselected tolerance settings.

up tp 50 fillets/min 280 mm 7-8 bar 2100x1200x1700 mm 1 kW 500 kg

Special Features

Technical Features

Productivity

Fish fillet width

Air connection

Dimensions

Power

Weight

Additional information

Low pressure forming machine of Marel of filled and unfilled products with a superior handmade look.

Special Features

Additional information

High pressure forming machine of Marel of a variety of convenience products such as: meat balls, schnitzels, burgers, nuggets and whole pieces.

Special Features

Additional information

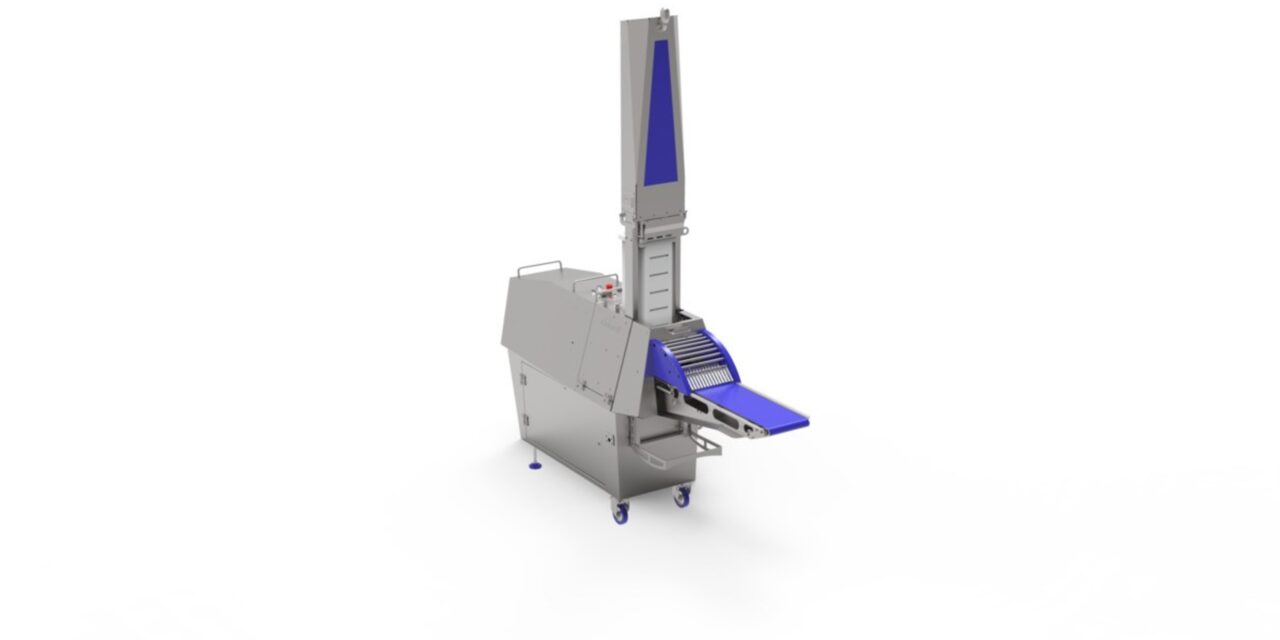

The Marel V-Cut 160 volumetric portion cutter is designed for small to medium-sized production volumes offering a variety of cuts into fixed weight portions of uniform shape. Suitable for cutting meat with or without bones. Also suitable for cutting meat with bones.

965x971x3130-3210 mm 960-1040 mm 0,75 kW ~425 kg

Special Features

Technical Specifications

Dimensions (ΜxΠxΥ):

Exit height:

Power:

Weight:

Additional information