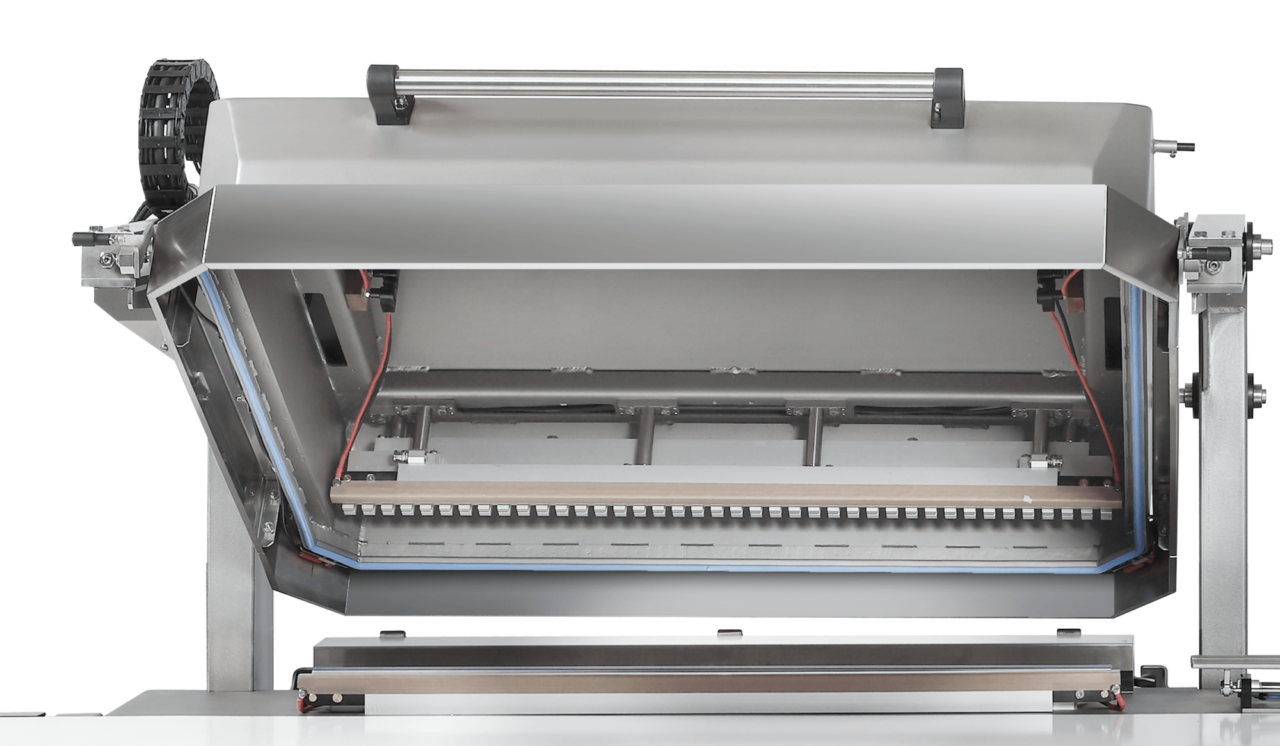

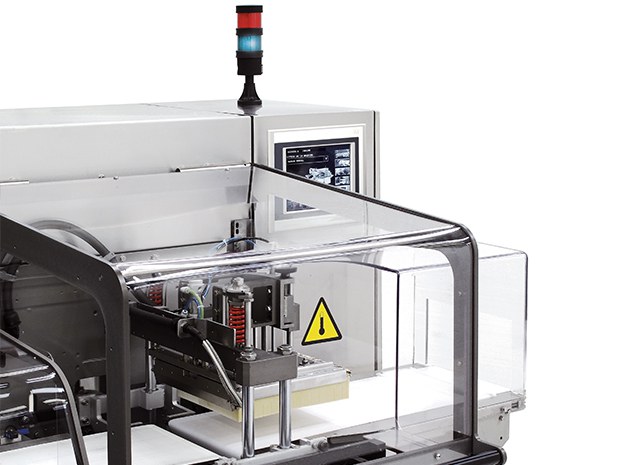

The WEBOMATIC easyPACK-mk³ table machine is used for quick vacuum packaging in food trade, supermarkets, gastronomy.

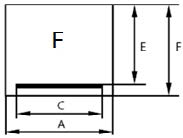

400x520x375 mm 360x395x140 mm 355 mm 2-3 cycles/min* ~55 kg 18 m³/h *Depending on package size and vacuum

Special Features

Technical Features

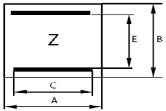

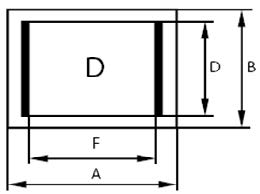

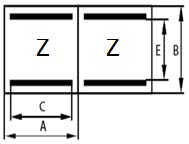

Dimensions (LxWxH)

Chamber dimensions (LxWxH)

Seal bar length

Capacity

Weight

Pump

Additional information