Versatile application

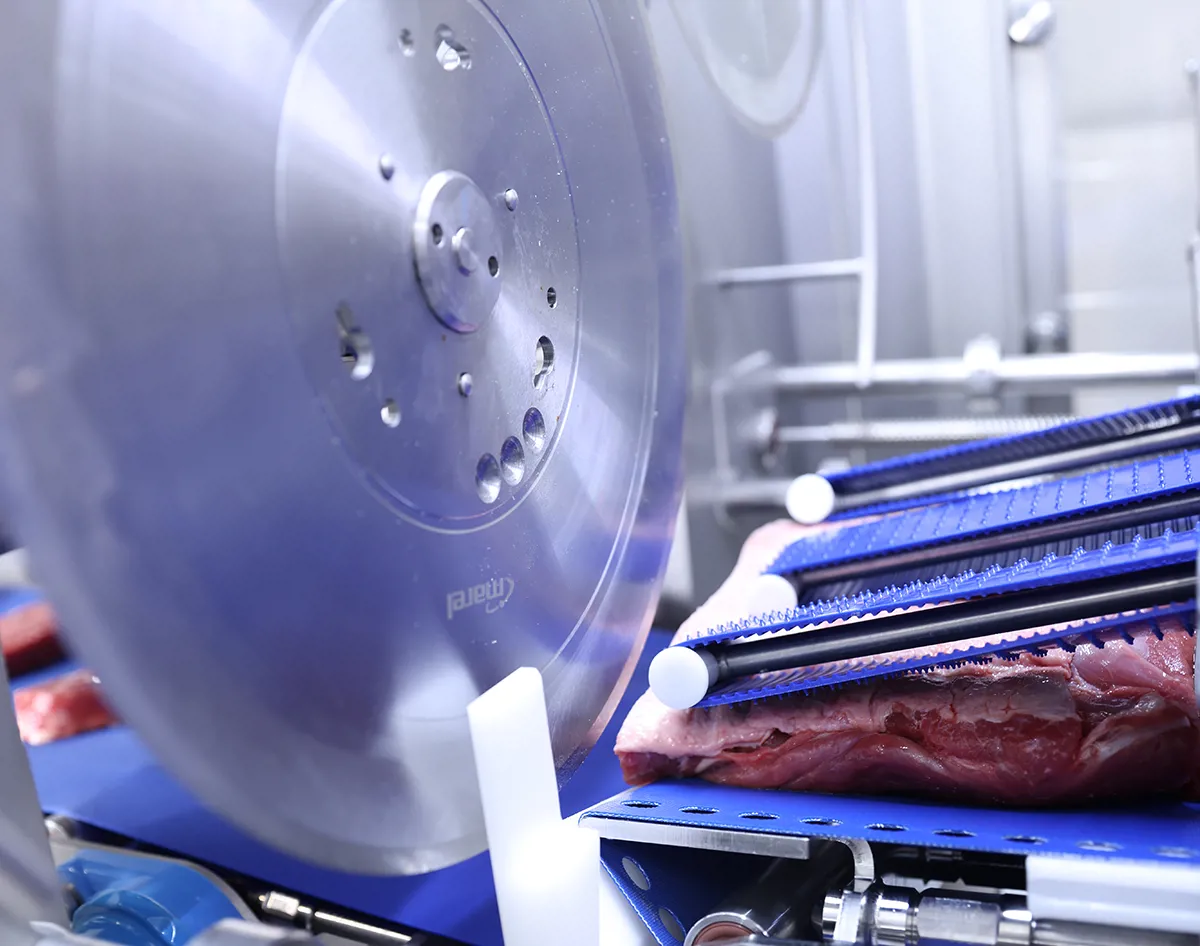

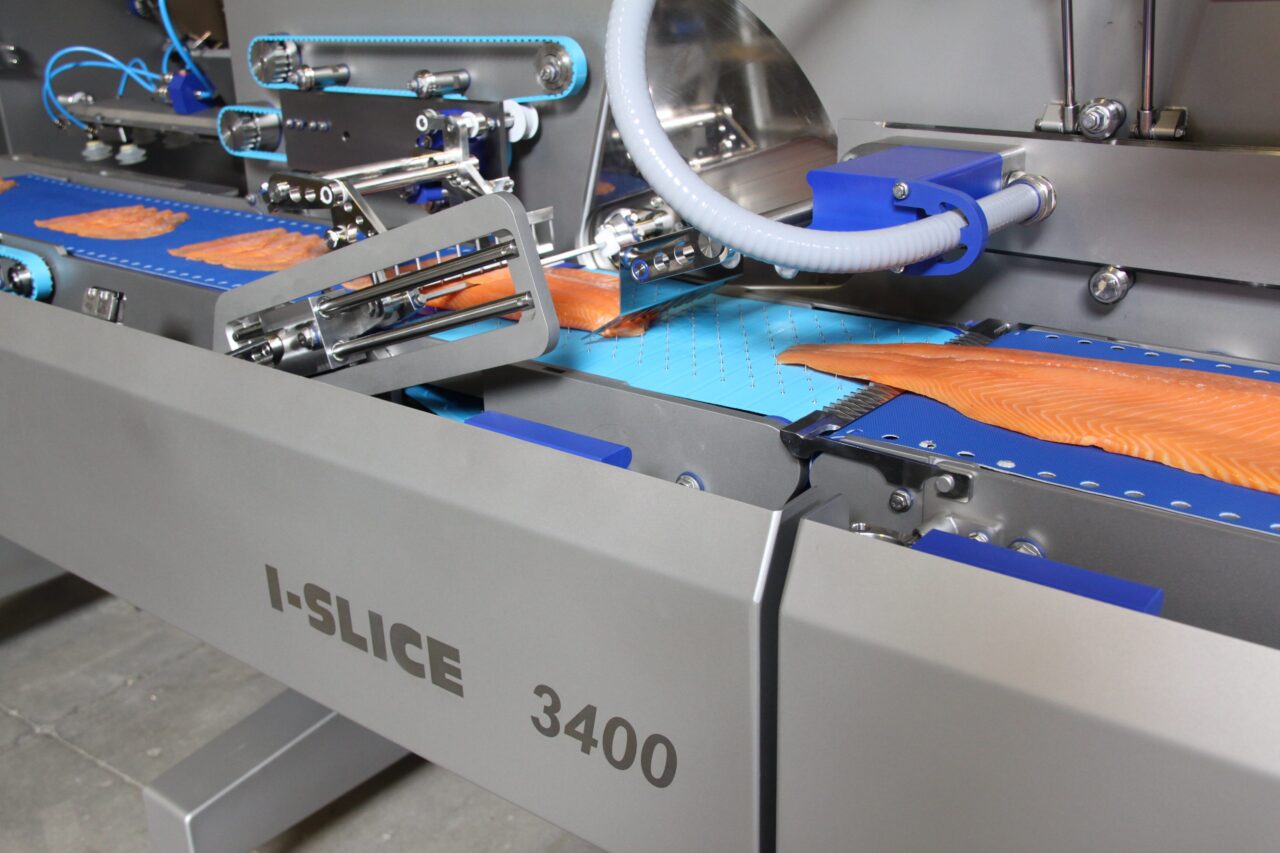

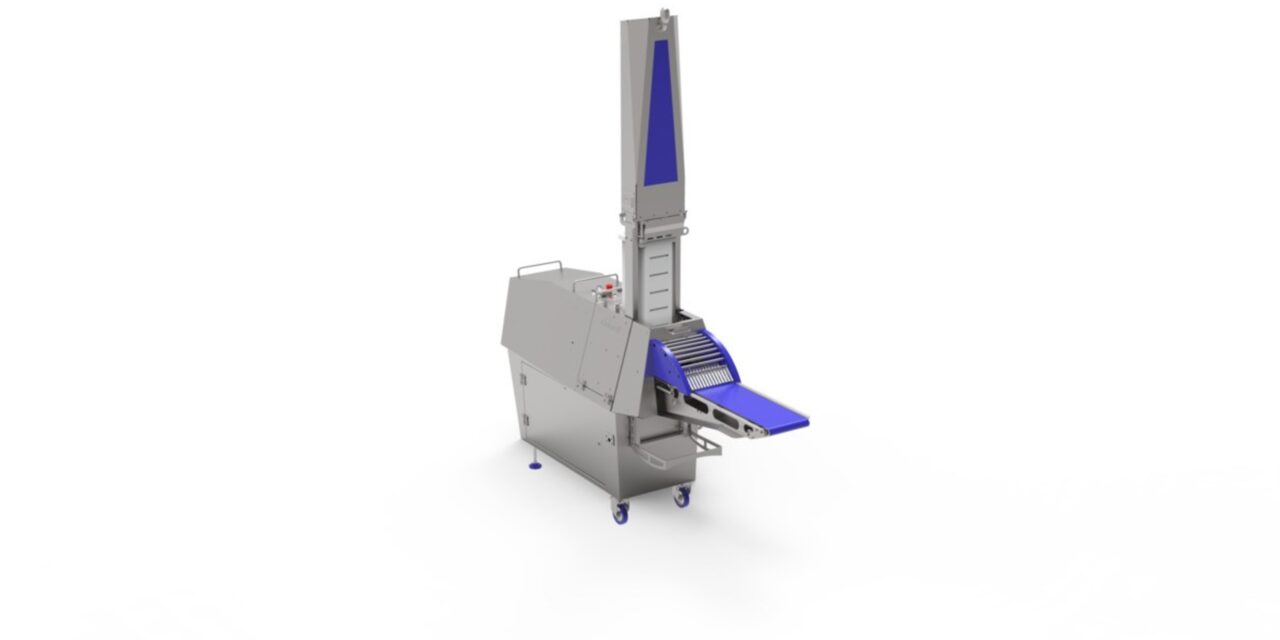

The circular blade cutting machine STC 400 is suitable for a big variety of slicing applications, e.g. slicing of fresh boneless poultry cuts from broilers, turkey and duck.

User friendly operation

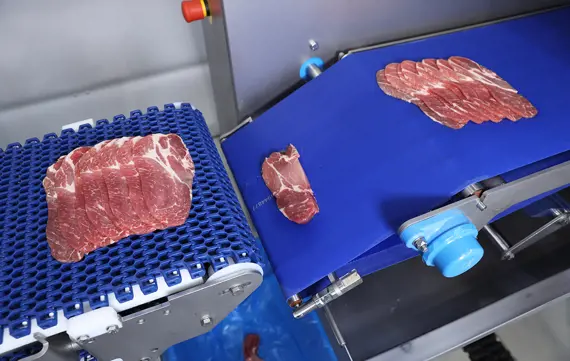

- The operator puts the cuts on the continuously driven infeed conveyor belt. They pass the circular cutting roller and within seconds, they are sliced to regular portions of consistent thickness

Large choice of cutting rollers

- The STC 400 is supplied without cutting rollers, as they have to be ordered separately according to individual cutting needs. Different rollers are necessary for different slice thicknesses, as the distance between the circular blades determines the cutting width, starting with 6 mm.

Short setup times for high operational availability

- Time-saving tool-free mounting and removal of machine parts for routine sanitation and upkeep

High safety standards

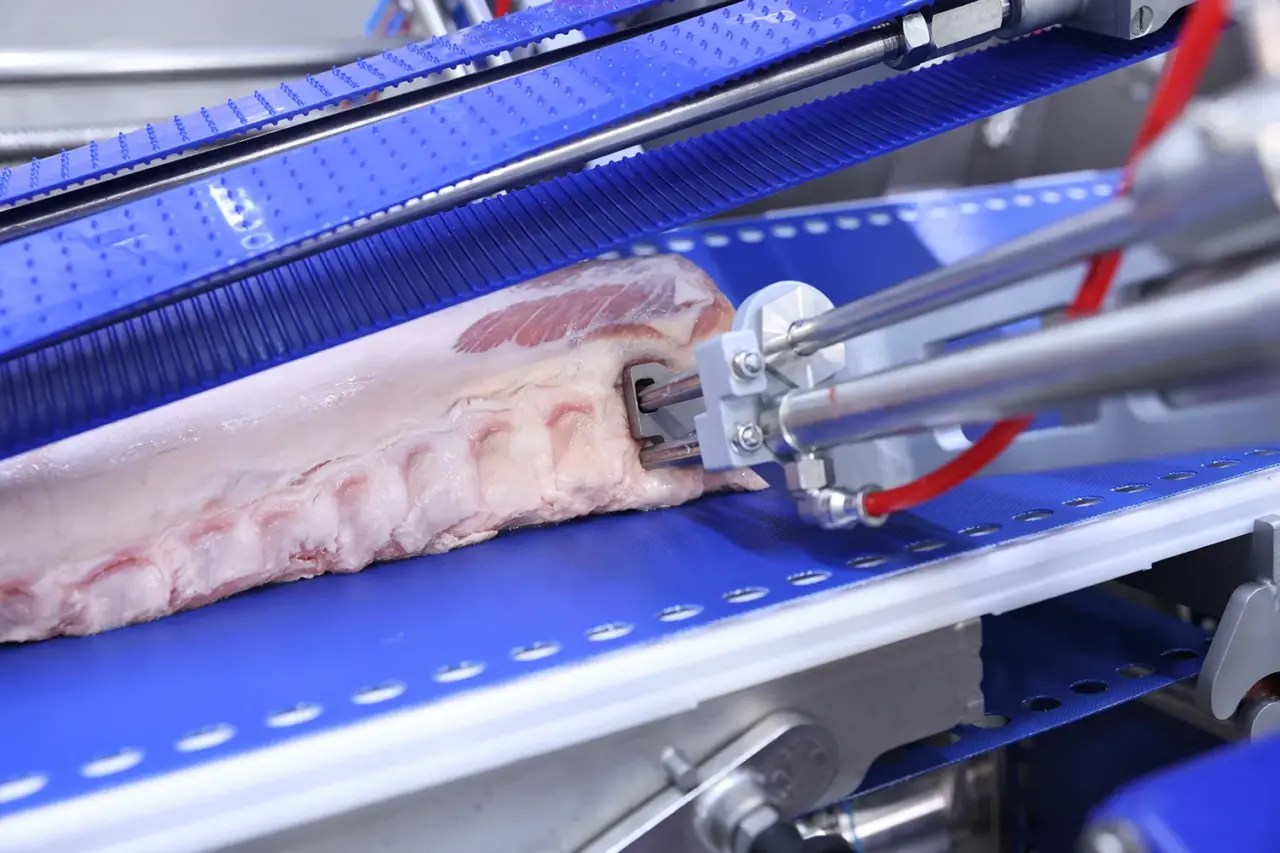

- For the safe mounting and removal of the circular blade roller, its holding device can be locked in a special setup position.

- Special safety handles for easy and safe removal of the cutting roller are included to allow cleaning and blade changes.

- For safe cutting roller cleaning, it is kept in a special cleaning box.

- Special protection covers on infeed and discharge conveyor belt according to current EU-regulations.

| Total cutting width |

283 mm |

| Max. product thickness |

~95 mm depending on the product |

| Dimensions (LxWxH) |

2185x766x1282 mm |

| Power |

1,5 kW |

| Weight |

265 kg |