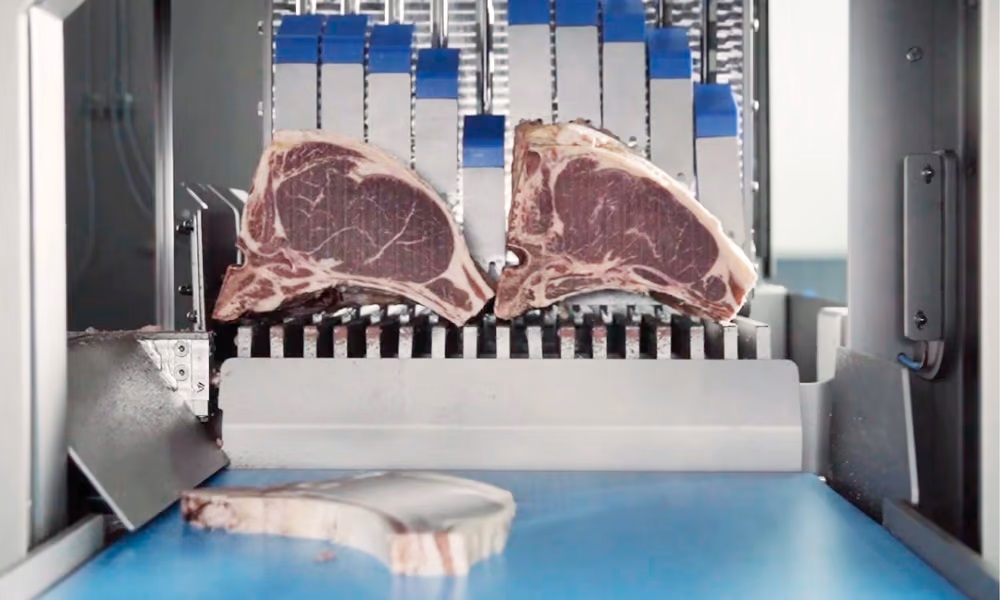

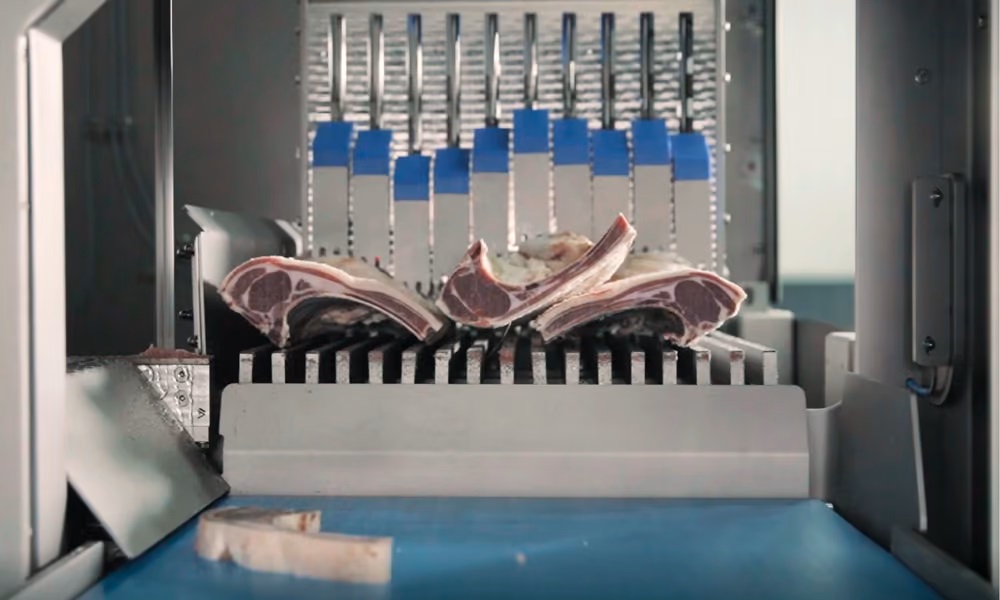

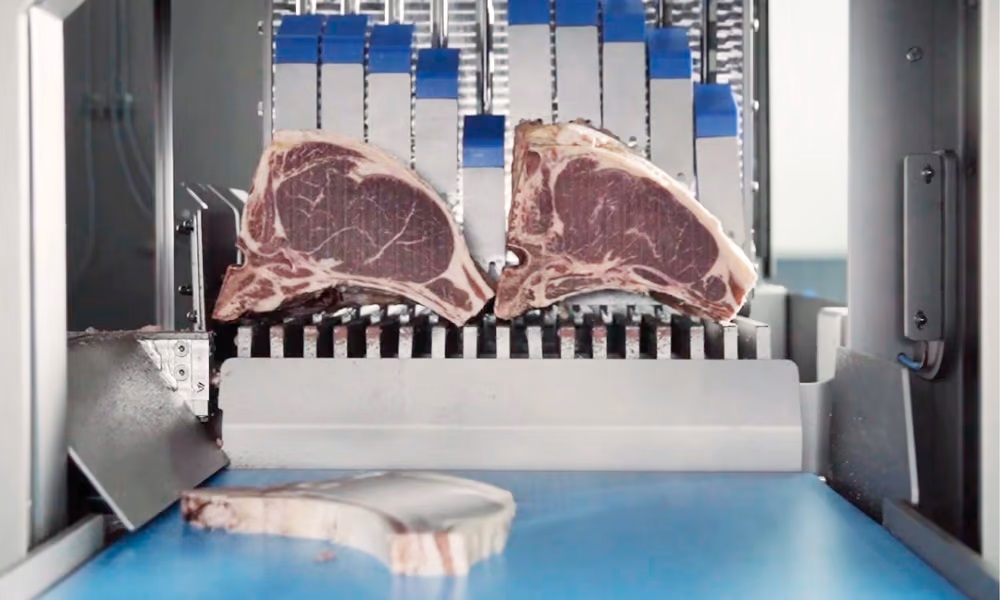

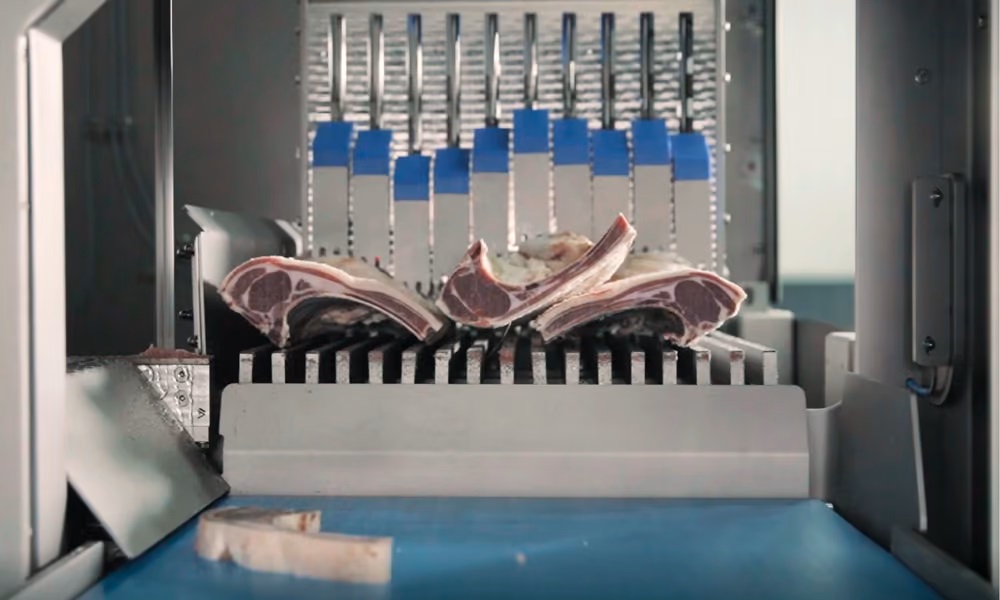

Astech presents the new bandsaw for the automatic cutting of frozen bone-in or boneless product, with very small dimensions and with a totally closed design that makes it very safe for work.

Technical specifications

Additional information

Astech presents the new bandsaw for the automatic cutting of frozen bone-in or boneless product, with very small dimensions and with a totally closed design that makes it very safe for work.

The Deheading Table MS 2510 is a highly efficient manual deheading solution designed for easy handling of salmon. A rotating buffer system automatically transfers the deheaded fish smoothly to the filleting station.

Special Features

Additional information

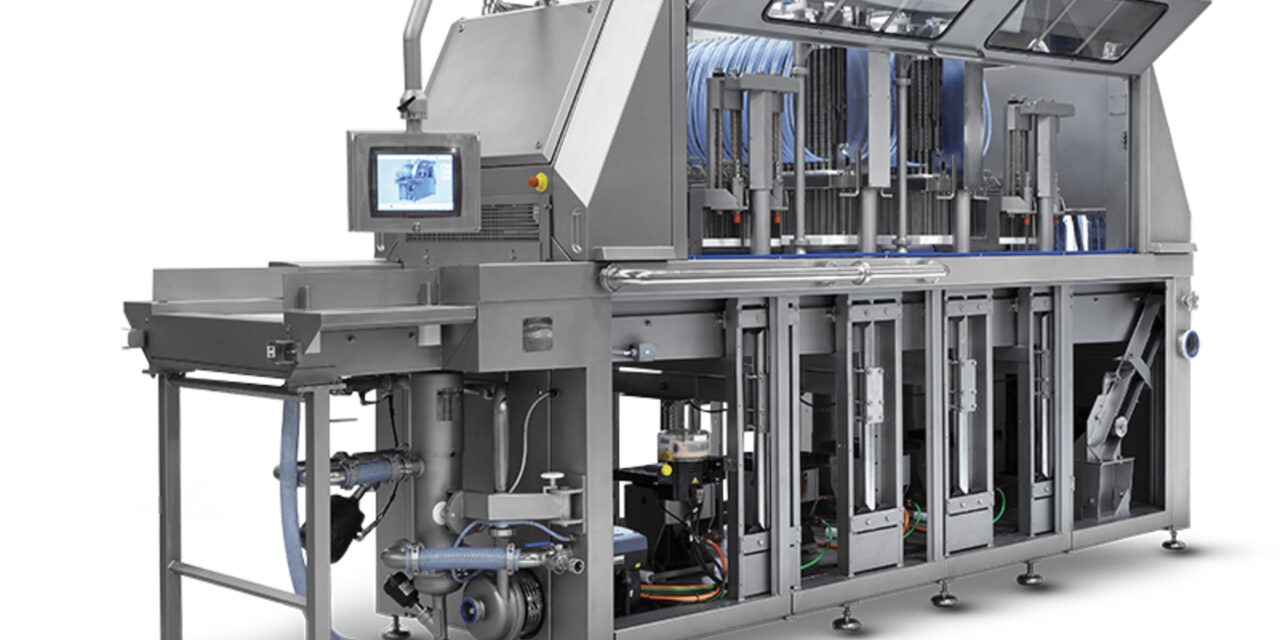

M2 series is both hygienic in production and easy to clean and offers various sizes of injectors depending on width of the transport systems Intuitive settings of pump pressure and production speed together with a constant read-out of brine temperature allows for precise and optimum food production.

Special features

Additional information

The automated beheader MS 2721 V is suitable for precise head and tail removal of salmon and other fish similar in size and texture.

up top 25 fishes/min 500 – 950 mm 58 – 120 mm 100 – 225 mm 2 – 10 kg from 1,8 mm 8 bar 4 l/min 3400x2100x2840 mm 3500 kg

Special Features

Technical Specifications

Maximum machine capacity

Fish length

Fish width

Fish height

Fish weight

Cutting width

Air supply

Water consumption

Dimensions (LxWxH)

Weight

Additional information

Designed for Beheading a wide variety of whitefish, the Curio Heading Machine possesses the ability to consistently process several species within the same parameters without changing equipment.

Special Features

Additional information

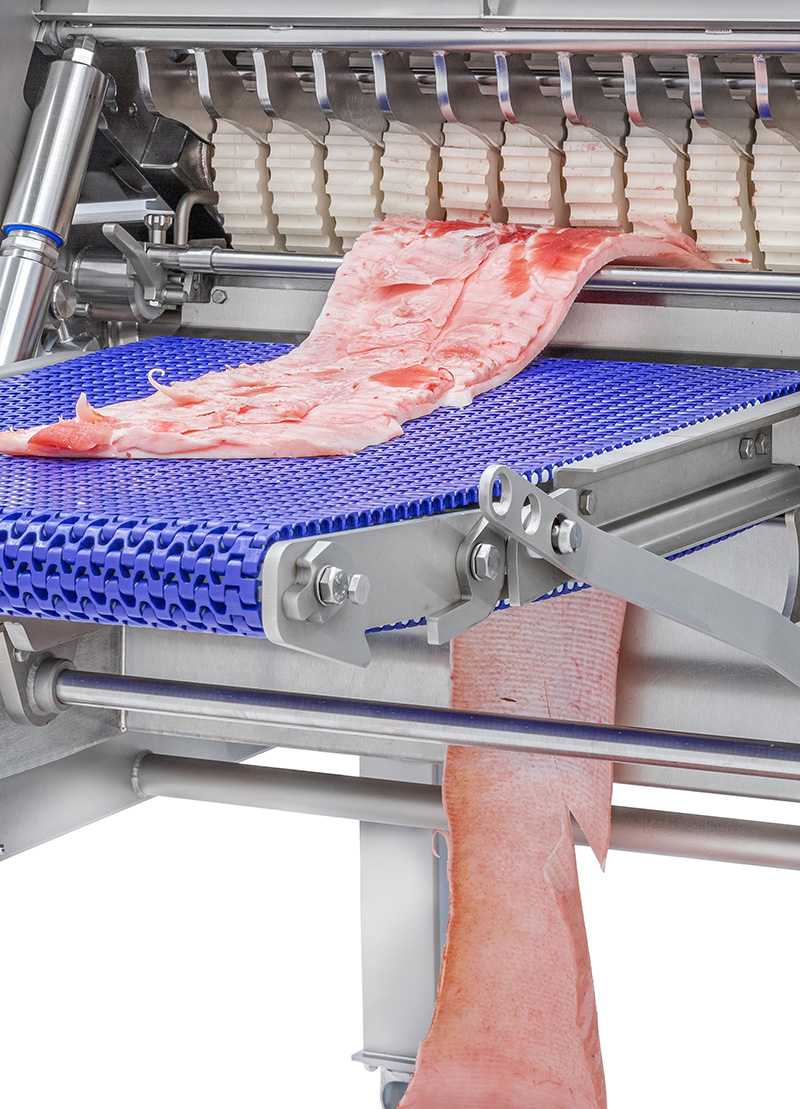

MAJA ESB derinding skinners are made for the safe derinding of flat meat cuts, poultry and fish through an infeed conveyor belt.

ESB 4434 V: Combined version for derinding and membrane skinning

ESB 4434 V: Combined version for derinding and membrane skinning

Special features

Versions

Versions

ESB 4434

4434/1

4600

Cutting width

434 mm

434 mm

599 mm

Dimensions(LxWxH)

853 mm

853 mm

1015 mm

Power

0,75 kW

0,75 kW

0,75 kW

Weight

235 kg

250 kg

280 kg

Versions

Versions

ESB 4434

Cutting width

434 mm

Dimensions(LxWxH)

853 mm

Power

0,75 kW

Weight

235 kg

Versions

4434/1

Cutting width

434 mm

Dimensions(LxWxH)

853 mm

Power

0,75 kW

Weight

250 kg

Versions

4600

Cutting width

599 mm

Dimensions(LxWxH)

1015 mm

Power

0,75 kW

Weight

280 kg

Additional information

The M3 comes in four different sizes, each with a different number of head configurations available, allowing for total customization. Due to the modular design, identical programs and because the exact same construction principles have been applied to all components and controls, installation and use have never been easier.

Special features

Additional information

The A-Skin is a fully automatic derinding skinner designed to easily remove skin and fat from pork and beef, without losing usable meat. Its design allows optimal use of the film removal drum ensuring maximum performance.

Cutting width 434 mm 554 mm 754 mm

Special Features

Versions

Version

A-Skin 45

A-Skin 55

A-Skin 75

Additional information

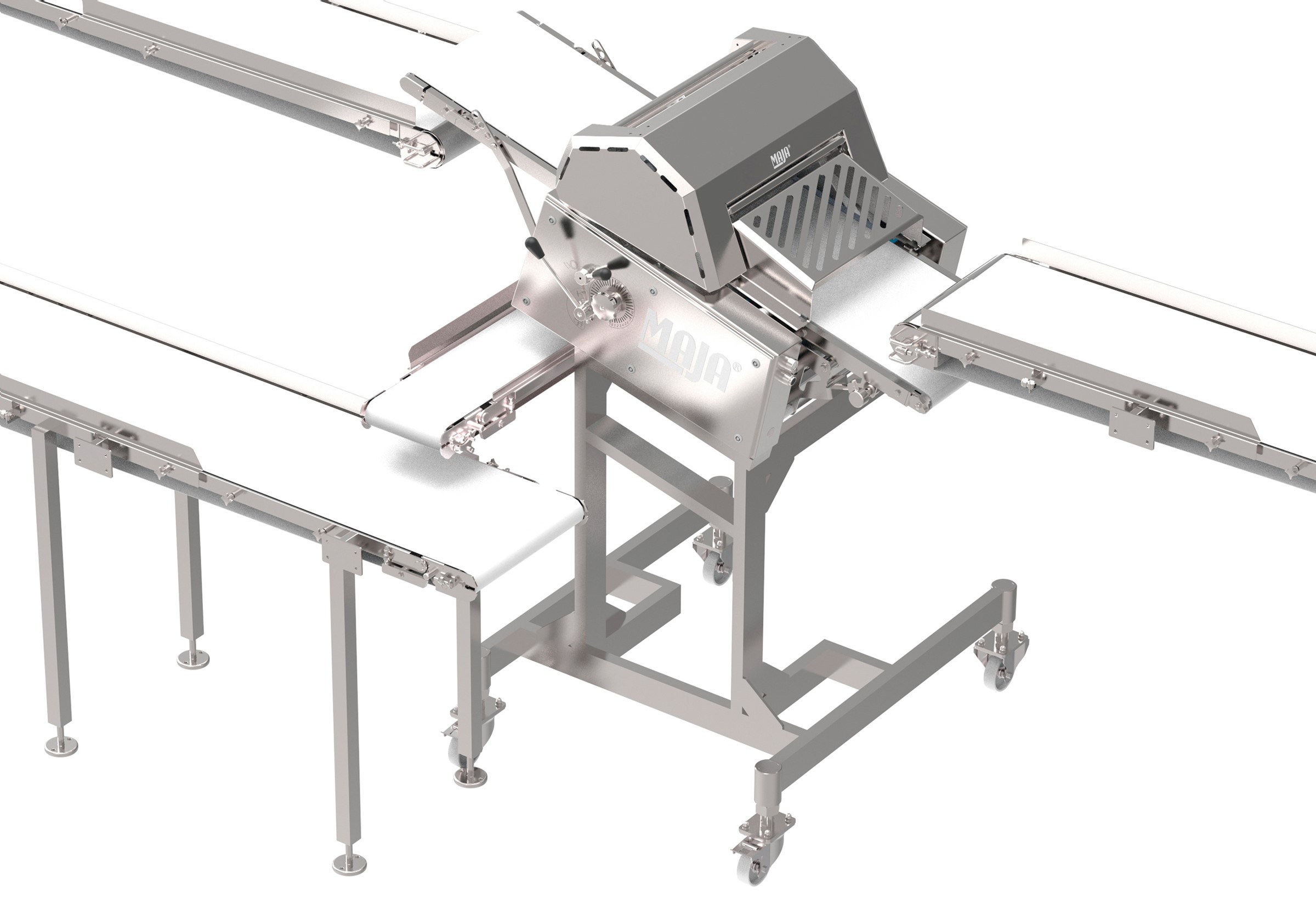

The BXAplus skinners are designed for conveyorized derinding of all fresh pork cuts.

BXAplus 434 BXAplus 754 434 mm 754 mm 1006x1912x1313 mm 1326x1912x1313 mm 1,1 kW 1,1 kW 350 kg 400 kg

BXAplus 434 434 mm 1006x1912x1313 mm 1,1 kW 350 kg

BXAplus 554 554 mm 1126x1912x1313 mm 1,1 kW 375 kg

BXAplus 754 754 mm 1326x1912x1313 mm 1,1 kW 400 kg

Special Features

Versions

Version

BXAplus 554

Cutting width

554 mm

Dimensions (LxWxH)

1126x1912x1313 mm

Power

1,1 kW

Weight

375 kg

Versions

Cutting width

Dimensions(LxWxH)

Power

Weight

Cutting width

Dimensions(LxWxH)

Power

Weight

Cutting width

Dimensions(LxWxH)

Power

Weight

Additional information

Skinner suitable for automatically skinning chicken breasts and legs bone in or boneless coming from air cooling. The system has an input and output conveyor belt. The machine has a special drum for processing the above products to minimize product damage and effective skinning. A special drum with springs automatically adjusts to each product entering the line.

Special Features

Special Features

Cutting width

434 mm

Dimensions (LxWxH)

853x1757x1242 mm

Power

0,55 / 0,88 kW

Weight

290 kg

Additional information